Method for designing loading trajectory of airplane skin lengthwise stretch forming and generating numerical control codes

A technology for loading trajectory and aircraft skin, applied in digital control, position/direction control, electrical program control, etc., can solve the problem of lack, the precise control function of numerical control drawing equipment fails to play, and it is difficult to meet the production of new aircraft skin parts requirements, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

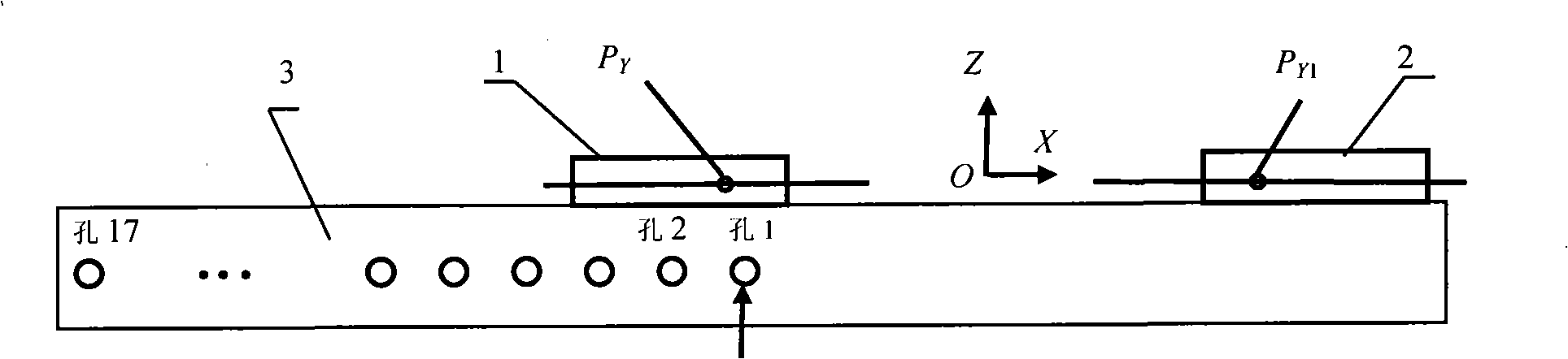

[0077] As shown in the accompanying drawings, a method for designing the loading trajectory of aircraft skin longitudinal stretching shape and NC code generation based on the numerical control longitudinal stretching machine, the specific implementation steps of the method are as follows:

[0078] Step 1: Longitudinal tensile loading trajectory design

[0079] 1. Initial hole position calculation

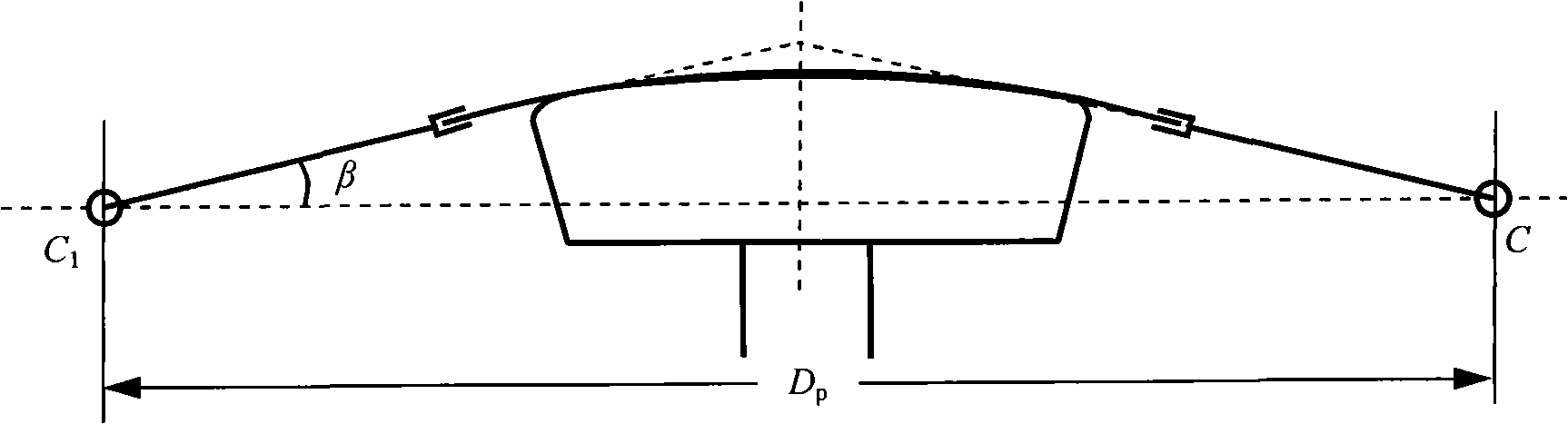

[0080] The initial hole position design is mainly based on the length of the wool and the Y rotation angle of the main shaft. figure 2 Shown is the geometric relationship of the tension state, the rotation angle of the main axis Y is β, and the fulcrum of the main axis is C 1 and C, C 1 The distance between and C is D p .

[0081] Let the wool length be L, the hole spacing be W, and the hole position be an integer n, then C 1 and the distance D between C p =D 0 +(n-1)W, when the hole position is 1, C 1 The distance between and C is D 0 . When the spindle extension is 0, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com