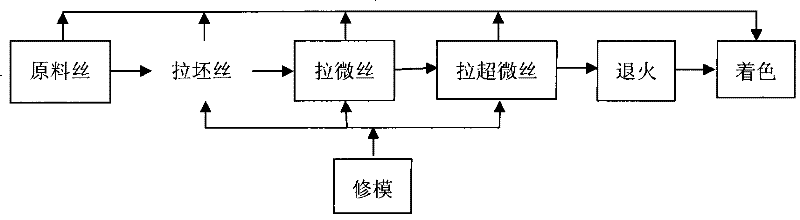

Production process of stainless steel superfine wire

A production process, stainless steel technology, applied in wire drawing dies, manufacturing tools, furnace types, etc., can solve problems such as high cost, disproportionate input and output, no profit, etc., to extend service life, ensure yield, and improve production efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0008] Embodiment 1: colored stainless steel ultrafine wire production process, it comprises stainless steel microwire process and stainless steel wire drawing machine, described stainless steel ultrafine wire drawing process is on the basis of stainless steel wire drawing process: (1) raw material selection: select φ0. 2mm stainless steel wire is used as raw material and drawn to φ0.035mm by a stainless steel wire drawing machine, as a billet wire drawn from φ0.018mm to 0.015mm; The inner diameters of the drawing dies are 0.030, 0.027, 0.025, 0.023, 0.021, 0.020, 0.019; , the billet is drawn through the above-mentioned set die and forming die to obtain microfilaments. (3) The microfilament passes through the high-temperature oxidizing atmosphere at a speed of less than 10 meters per second, and a transparent film with a thickness of tens to hundreds of nanometers is formed on the surface of the microfilament. Films with different thicknesses and different compositions present...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com