Copper based metal powder

A technology of metal powder and copper powder, applied in the field of copper, copper alloy and copper-based mixed powder, to achieve the effect of improving productivity and improving fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

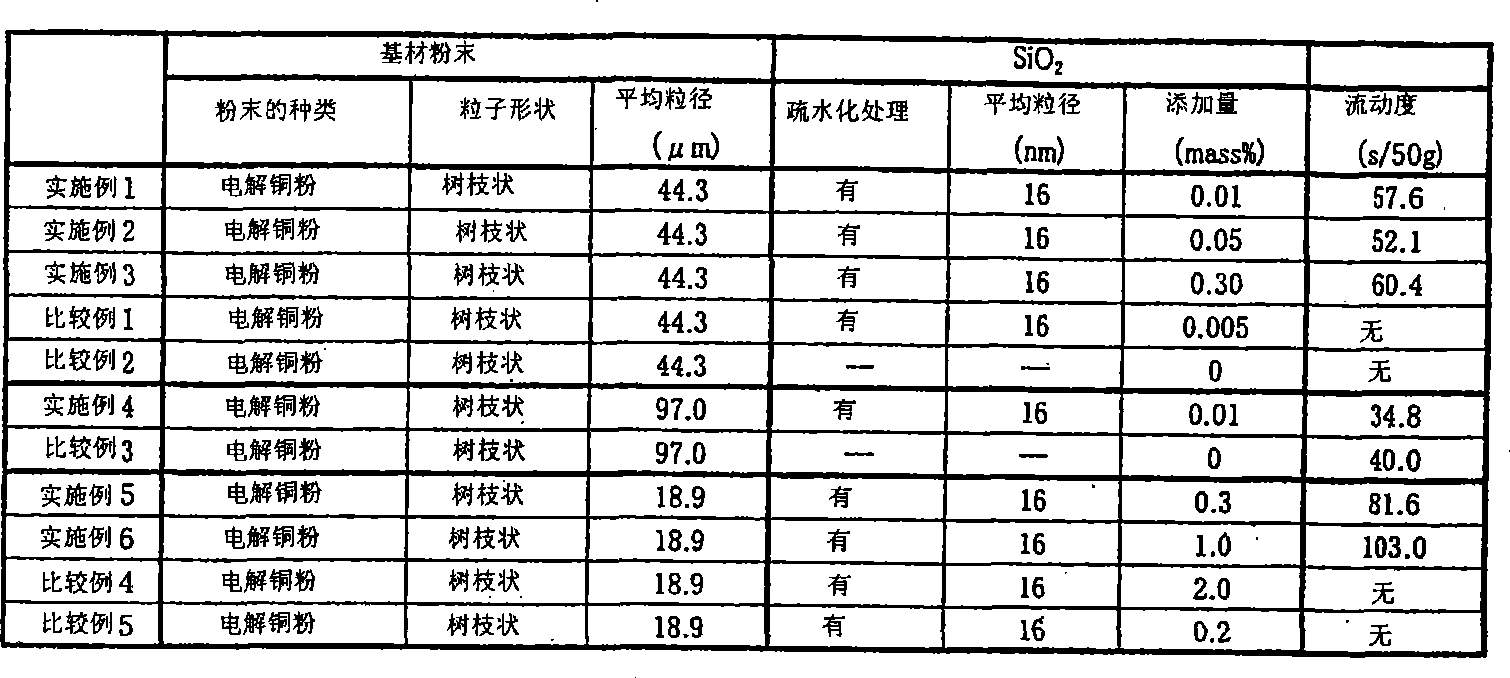

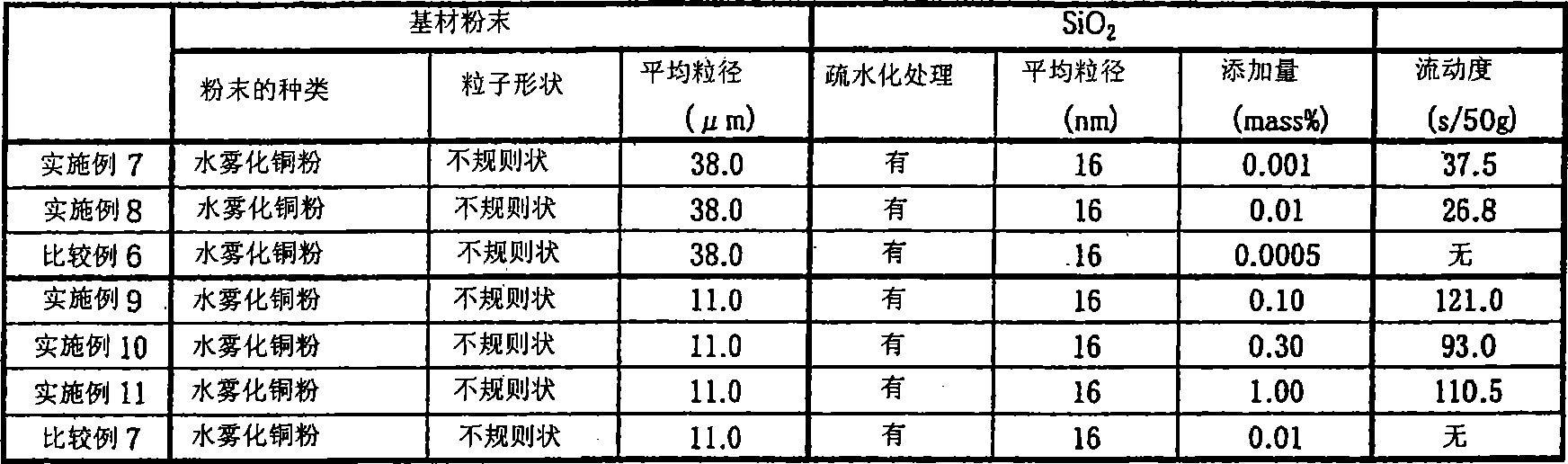

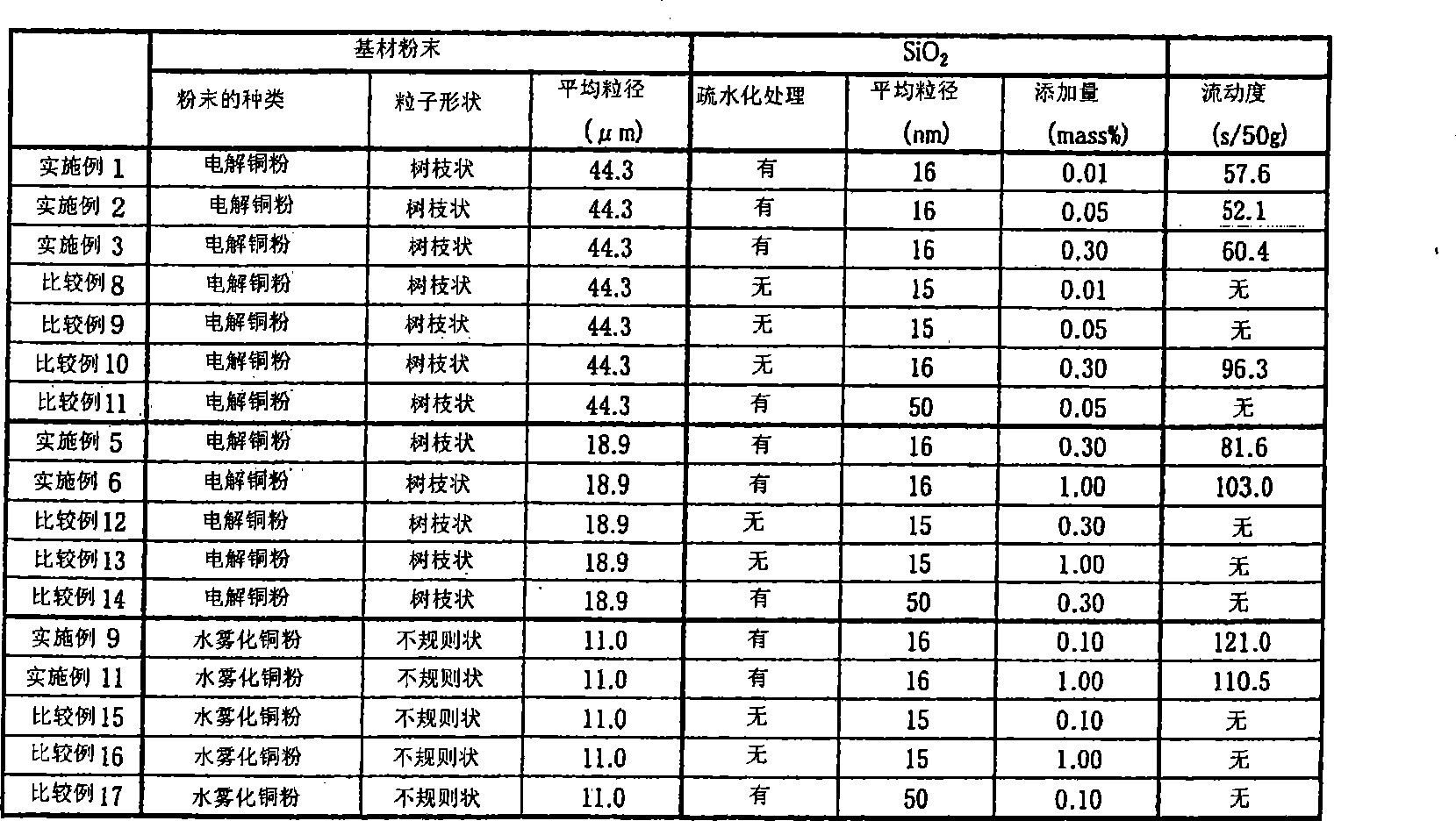

Examples

Embodiment 12

[0054] Example 12 shows the addition of SiO to water atomized bronze powder with an average particle size of 35.6 μm 2 The effect of improving fluidity is shown in Example 13 by adding SiO to water atomized bronze powder with an average particle size of 10.3 μm 2 Although the fluidity improvement effect brought about was substantially equivalent to that of water atomized copper powder having an average particle diameter of the same level, the improvement effect was confirmed.

[0055] Table 5 shows the effect of improving fluidity of powders in which auxiliary component powders and lubricants are mixed with copper powders as additional powders. Also, SiO in the following Table 5 2 The added amount is out% with respect to the total mass of copper powder, subcomponent powder, and lubricant.

[0056] 【table 5】

[0057]

Embodiment 14

[0058] Example 14 shows that SiO is added to a mixed powder of electrolytic copper powder and 10% water atomized tin powder, in which 0.5out% of zinc stearate is added as a forming lubricant. 2 The result of 0.05% in Comparative Example 18 is to show that no addition of SiO 2 results when adding SiO 2 When the content is 0.05%, the fluidity improvement effect is seen.

Embodiment 15

[0059] As shown in Example 15, SiO was added to a mixed powder of electrolytic copper powder and 2% graphite powder, in which 0.5 out% of EBS resin was added as a wax-based lubricant as a molding lubricant. 2 The results of Comparative Example 19 showed no addition of SiO 2 results when adding SiO 2 When it reaches 0.05%, the fluidity improvement effect is seen.

[0060] As shown in Table 6, Al is used as a fluidity improving material 2 o 3 , or use TiO 2 , MgO, and SiO mixed in a ratio of 1:1:1:1 using 2 、Al 2 o 3 、TiO 2 , The fluidity improvement effect of the mixture of MgO. Also, SiO with hydrophobic treatment 2 、Al 2 o 3 、TiO 2 and MgO are used on the market.

[0061] 【Table 6】

[0062]

[0063] *: Mix SiO at a ratio of 1:1:1:1 2 , Al 2 o 3 ,TiO 2 , MgO

[0064] As shown in Examples 16 to 19, the fluidity improvement effect was obtained in all.

[0065] As described above, if the fluidity improving material used in the present invention is not subje...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com