Method for realizing changing content on-line print and mixing digital printing system

A digital printing and content technology, which is applied to the general parts of printing machinery, printing, printing machines, etc., can solve the problems of rotary printing machines that cannot be docked, and achieve high work efficiency and product cost, strong anti-counterfeiting capabilities, and low printing costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

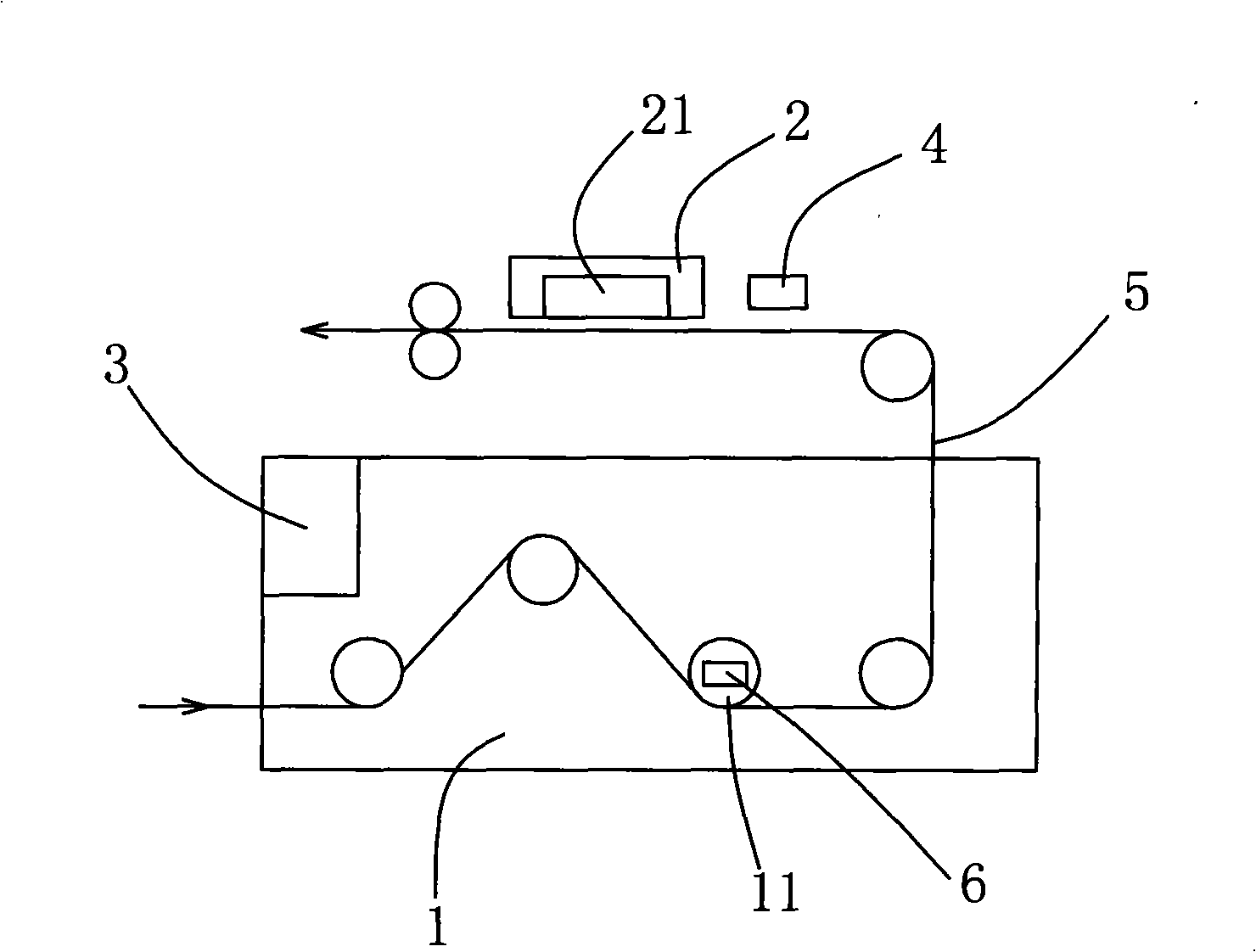

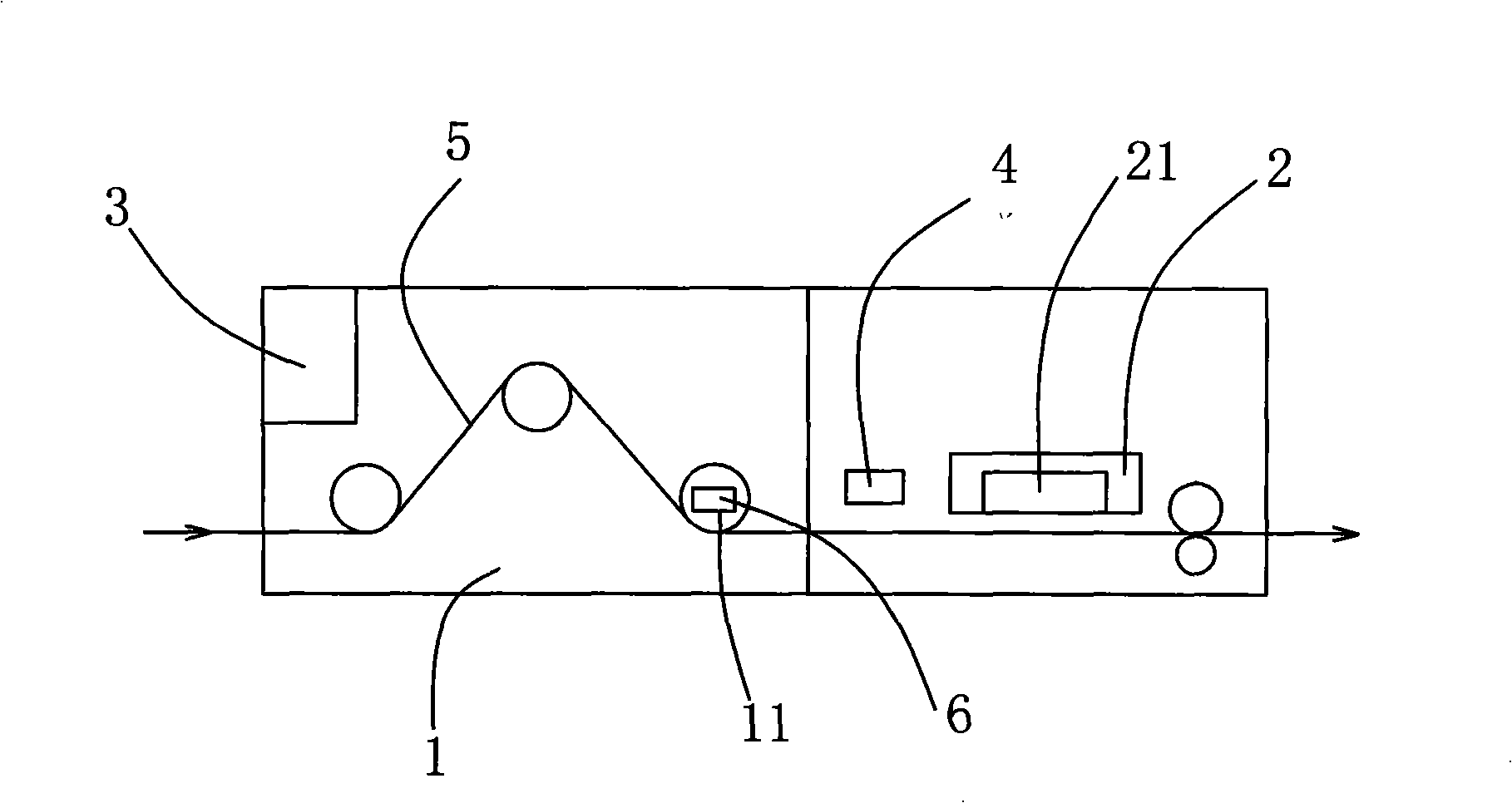

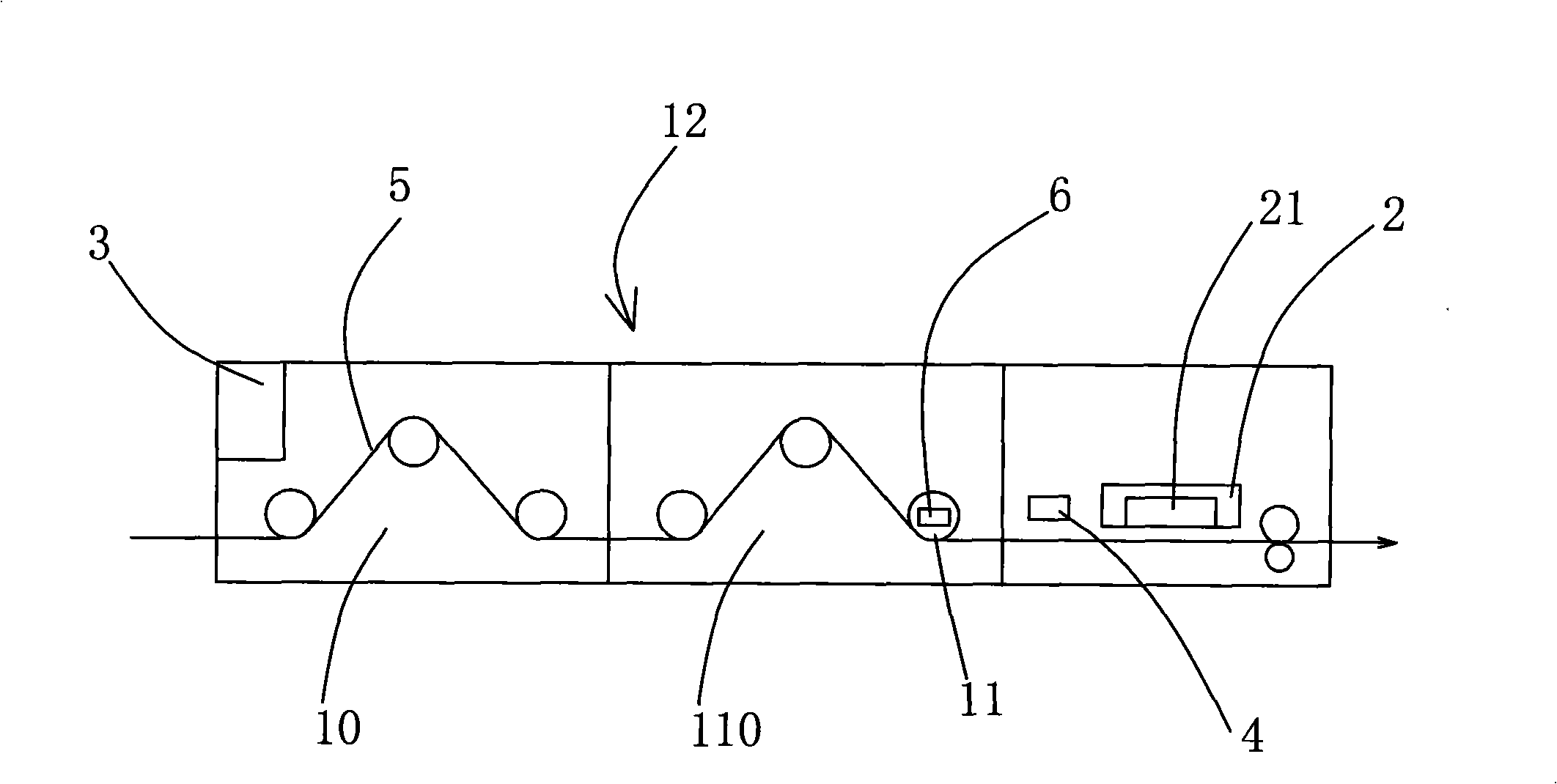

[0038] See figure 1 , figure 1 It is a structural schematic diagram of an embodiment of the present invention. It is a hybrid digital printing system, including a rotary printing machine 1, the rotary printing machine in this embodiment is an offset printing machine; above the offset printing machine, a multi-color inkjet digital printing unit 2 is provided, and the multi-color inkjet digital printing unit 2 is provided. The color inkjet digital printing unit 2 is a four-color inkjet digital printing machine, which is produced by a company in Beijing. Obviously, the multi-color inkjet digital printing unit 2 can also use six colors and four color inkjet digital printing machine; a central control unit 3, the central control unit 3 is arranged on the rotary printing machine 1, obviously, the central control unit 3 can also be set up separately, as long as it is convenient to operate; the central control unit The unit includes a rotary encoding control subunit, a color code in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com