Natural oil for wood products

A natural oil and product technology, applied in the direction of oxidized linseed oil paint, etc., can solve the problem of unsatisfactory use effect of natural paint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

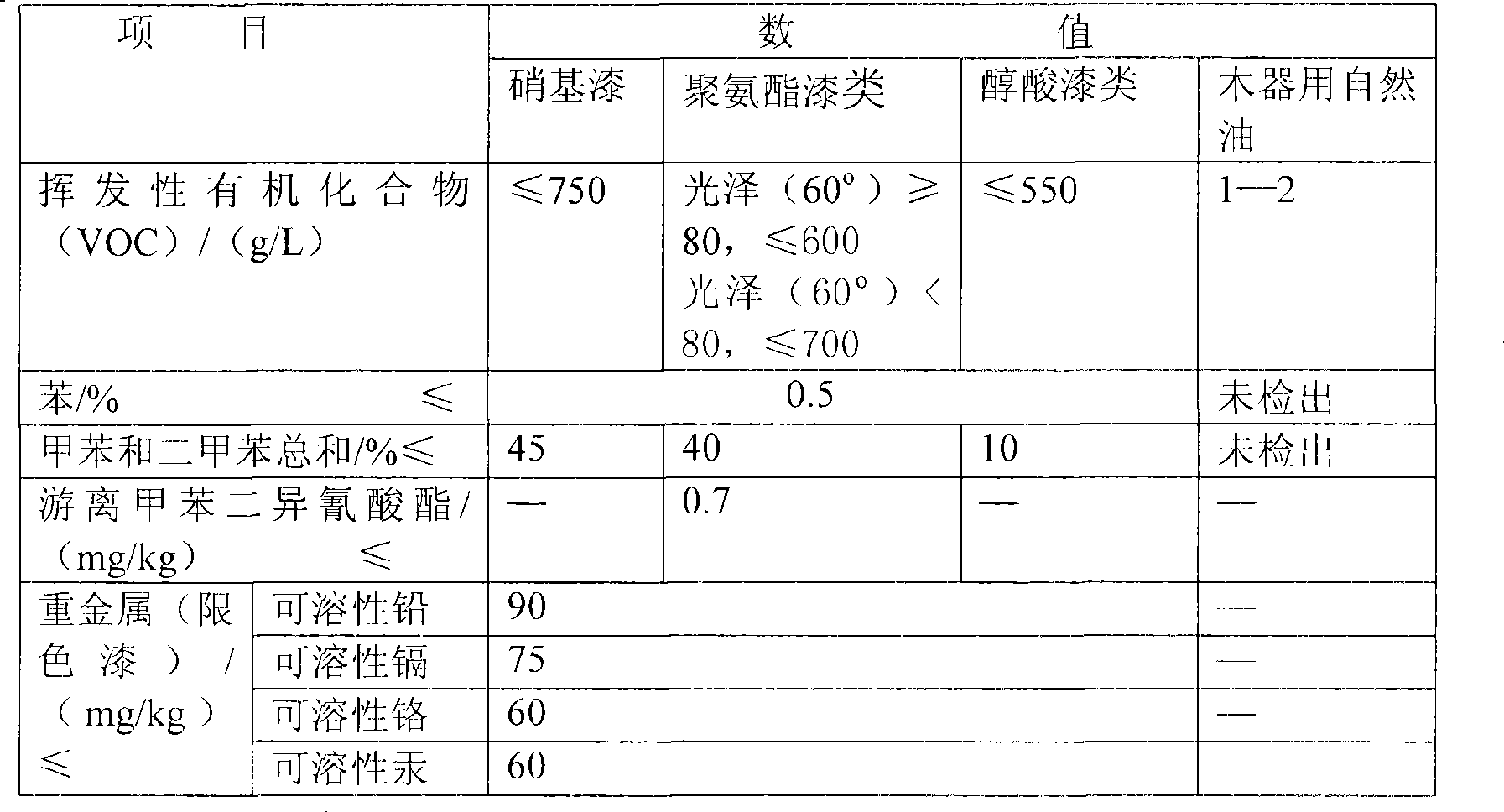

Image

Examples

example 1

[0071] Add the refined linseed oil into a three-necked bottle, stir, ventilate, and react for 8 hours at 145°C to make polymerized linseed oil. Take 785 grams of polymerized linseed oil, 25 grams of carnauba wax, 20 grams of candelilla wax, 21 grams of beeswax, 6 grams of cobalt naphthenate, 6 grams of anti-skinning agent, 4 grams of ultraviolet absorber and 8 grams of antifoaming agent, carnauba wax, candelilla wax, beeswax are respectively heated to melting temperature respectively, Add together into polymerized linseed oil and mix well, cool down to 30°C, then add cobalt naphthenate and mix well, add anti-skinning agent and mix well, add ultraviolet absorber and stir mix well, add defoamer and stir mix Uniform, made into natural oil for wood products.

example 2

[0073] Take 500 grams of polymerized linseed oil, 100 grams of carnauba wax, 100 grams of candelilla wax, 2 grams of manganese naphthenate, 8 grams of anti-skinning agent, 6 grams of ultraviolet absorber and 1 gram of defoamer, and mix carnauba wax , candelilla wax were heated to their respective melting temperatures and melted, then added to the polymerized linseed oil and stirred evenly, cooled down to 20°C, then manganese naphthenate was added in turn, stirred evenly, and anti-skinning agent was added, stirred evenly, Add the ultraviolet absorber and stir and mix evenly, add the defoamer and stir and mix evenly, and make the natural oil for woodware products.

example 3

[0075] Add the refined linseed oil into a three-necked bottle, stir, ventilate, heat up to 140°C and react for 8 hours to make polymerized linseed oil. Take 900 grams of polymerized linseed oil, 45 grams of carnauba wax, 15 grams of rare earth naphthenate, 3 grams of anti-skinning agent, 1 gram of ultraviolet absorber, heat the carnauba wax to the melting temperature and melt, add to the polymerized linseed oil and stir and mix evenly, cool down to 35 ° C, then add the rare earth naphthenic acid in turn, stir and mix evenly, Add anti-skinning agent and stir to mix evenly, add ultraviolet absorber to stir and mix evenly to make natural oil for wood products.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap