High temperature valve

A valve, high-temperature technology, applied in the field of high-temperature valve devices, can solve the problems of difficult popularization, short service life, hidden safety hazards, etc., and achieve the effects of reducing production costs, improving service life, and reducing cracks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

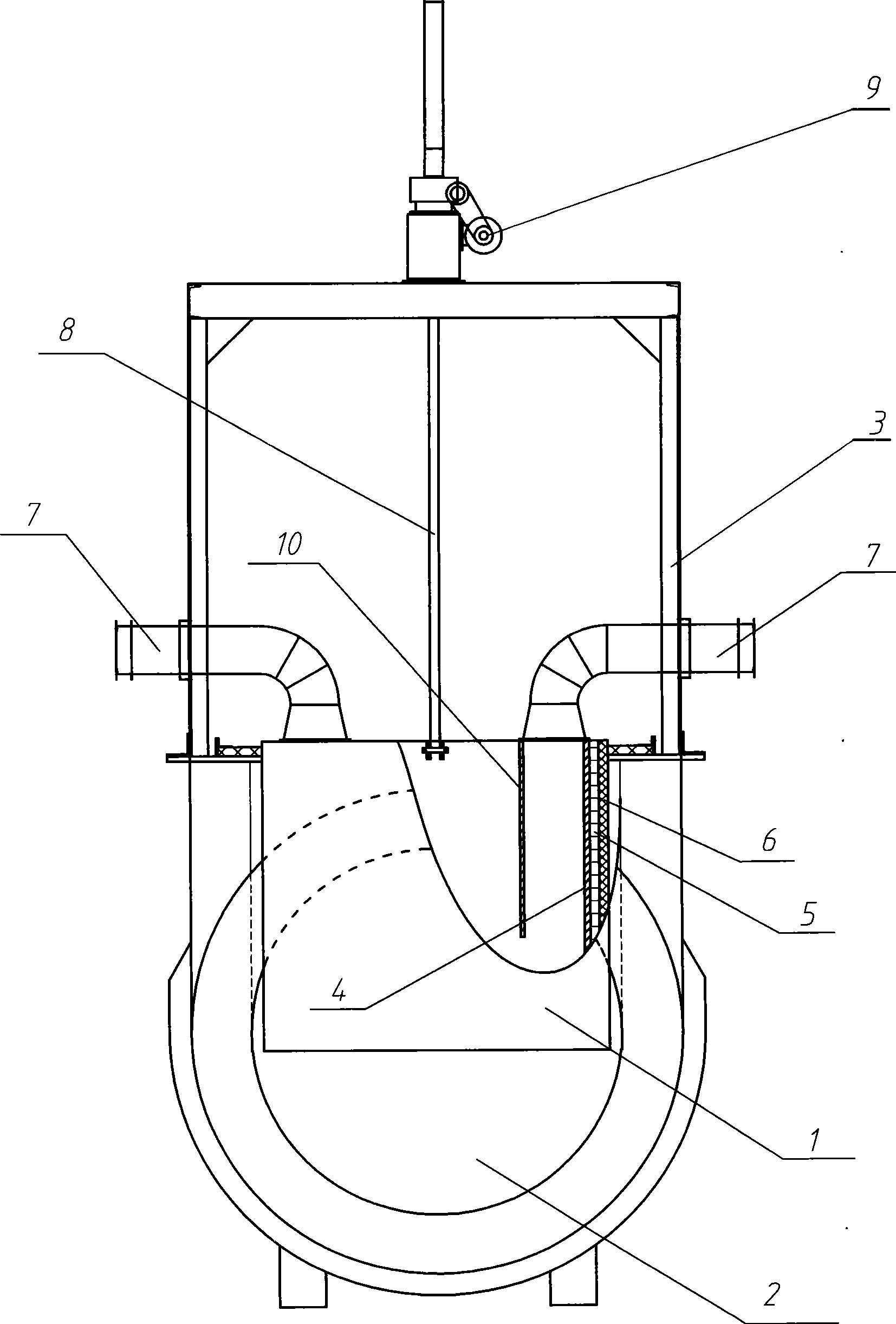

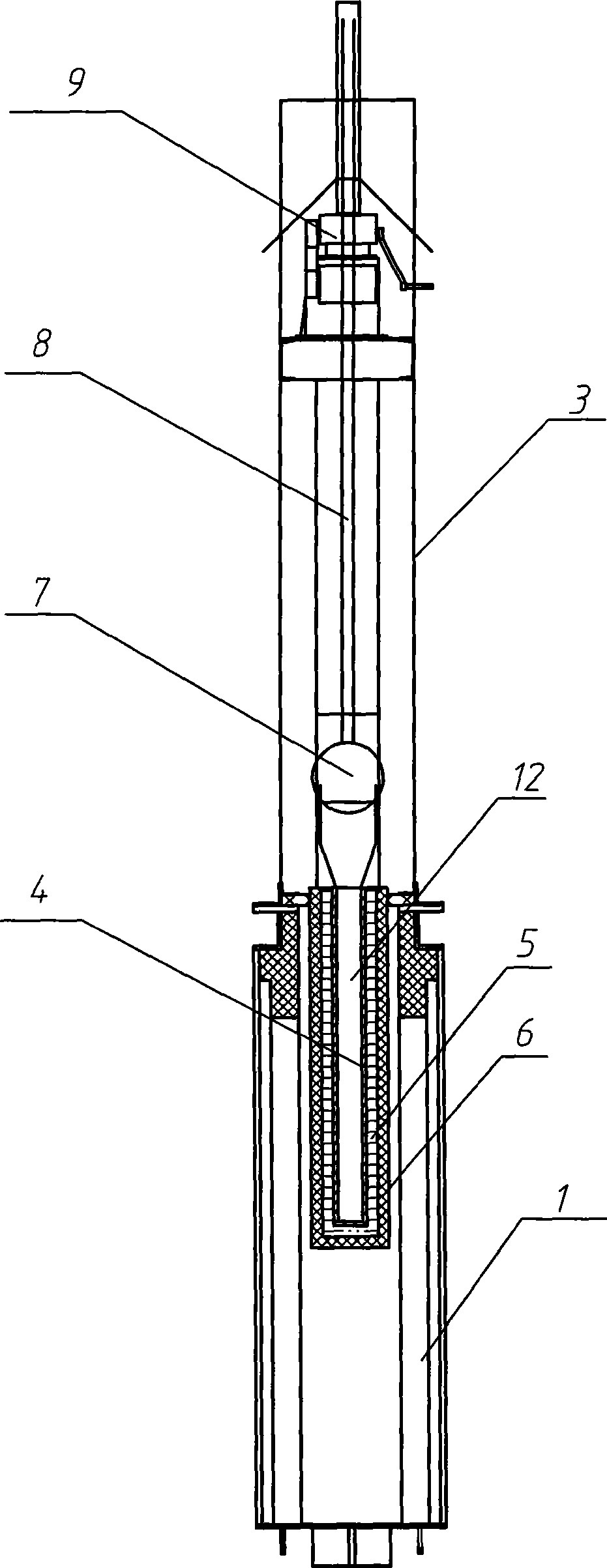

[0012] Such as figure 1 As shown, the valve plate 2 on the valve body 1 is movably connected to the lower part of the door frame 3, and the hoist 9 is installed on the door frame 3, and connected to the valve plate 2 through a screw rod 8, which is used to adjust the valve plate 2 to the valve body 1. opening and closing. The valve plate 2 is a cavity structure, and the left and right air inlet pipes 7, 17 are respectively installed on the top of the valve plate 2 through the air inlets 13, 23 on the valve plate 2 and connected to the cavity 12. The other ends of the air inlet pipes 7, 17 Connect the external fan, and the external fan blows cold air into the cavity 12 through the air inlet pipes 7 and 17; figure 1 The middle curve A is the partial cross-sectional line of the valve plate 2. As shown in this partial cross-sectional view, the cold air sent by the air inlet pipe 7 enters the inner cavity of the valve plate 2, and is guided by the inner cavity wall 4 and the air d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com