Manufacture method of zinc-iron alloy standard template

A production method and a technology of standard templates, which are applied in the preparation of test samples, test metals, and measuring devices, can solve problems such as long time periods, inability to ensure accuracy, and poor control of iron content, and achieve zinc consumption reduction, The effect of improving product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0026] (1) Sampling: DC56 is used as the strip steel steel, and the steel specification is 0.65×1100mm. The steel is hot-dip galvanized, and the process parameters are set as air knife height 300mm, air knife distance 8.5mm / 8.5mm, unit speed 80m / min, and zinc pot temperature 460°C. In this case, the air knife pressure is 200- 650mbar, the air knife power is 20-70, the air knife pressure value is 200mbar, 350mbar, 500mbar, 650mbar in equal proportion, and the air knife power value is 20, 30, 40, 50, 60, 70, as shown in Table 1 Sampling form, samples of 24 specifications can be collected, each specification produces 100-150m meters, after production, the strip steel of each specification is sent to the finishing cross-cutting machine for cutting, and six pieces are reserved for each specification, and the final target sample is required The size is 200*200mm.

[0027] Table 1 Formulation table for sample sampling

[0028]

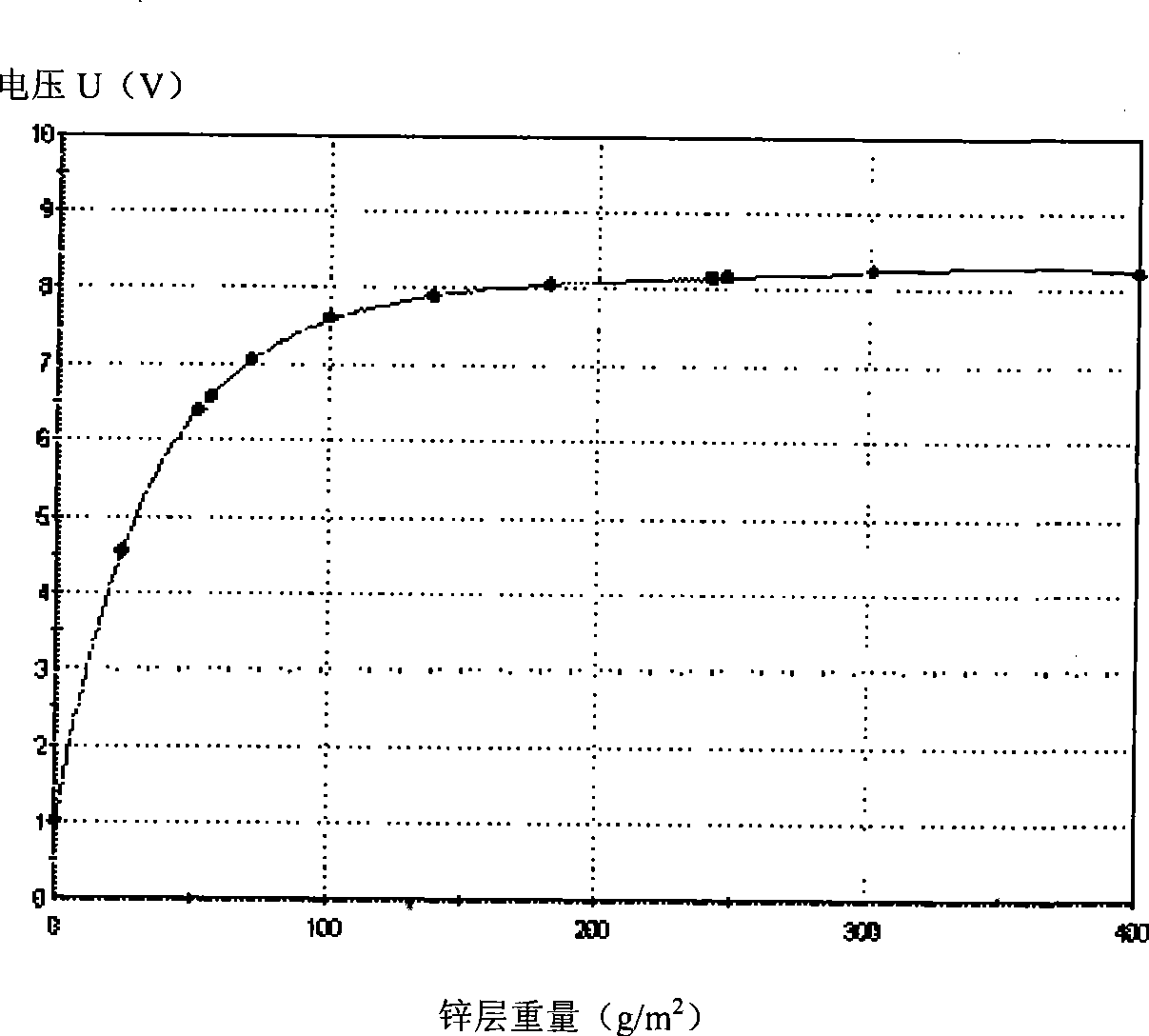

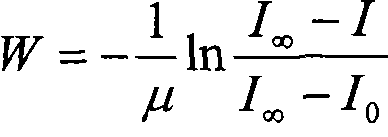

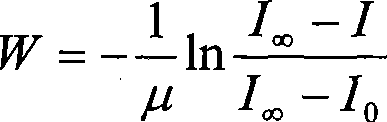

[0029] (2) Uniformity test: use the high-precision...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com