Process for producing nitride semiconductor, crystal growth rate enhancement agent, nitride single crystal, wafer and device

A technology of nitride semiconductors and manufacturing methods, which is applied in semiconductor/solid-state device manufacturing, single crystal growth, single crystal growth, etc., and can solve problems such as different growth rates, impurity concentrations, and number of crystal defects, and the inability to obtain uniform quality wafers, etc. , to achieve the effect of increased growth rate, excellent quality and homogeneous quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

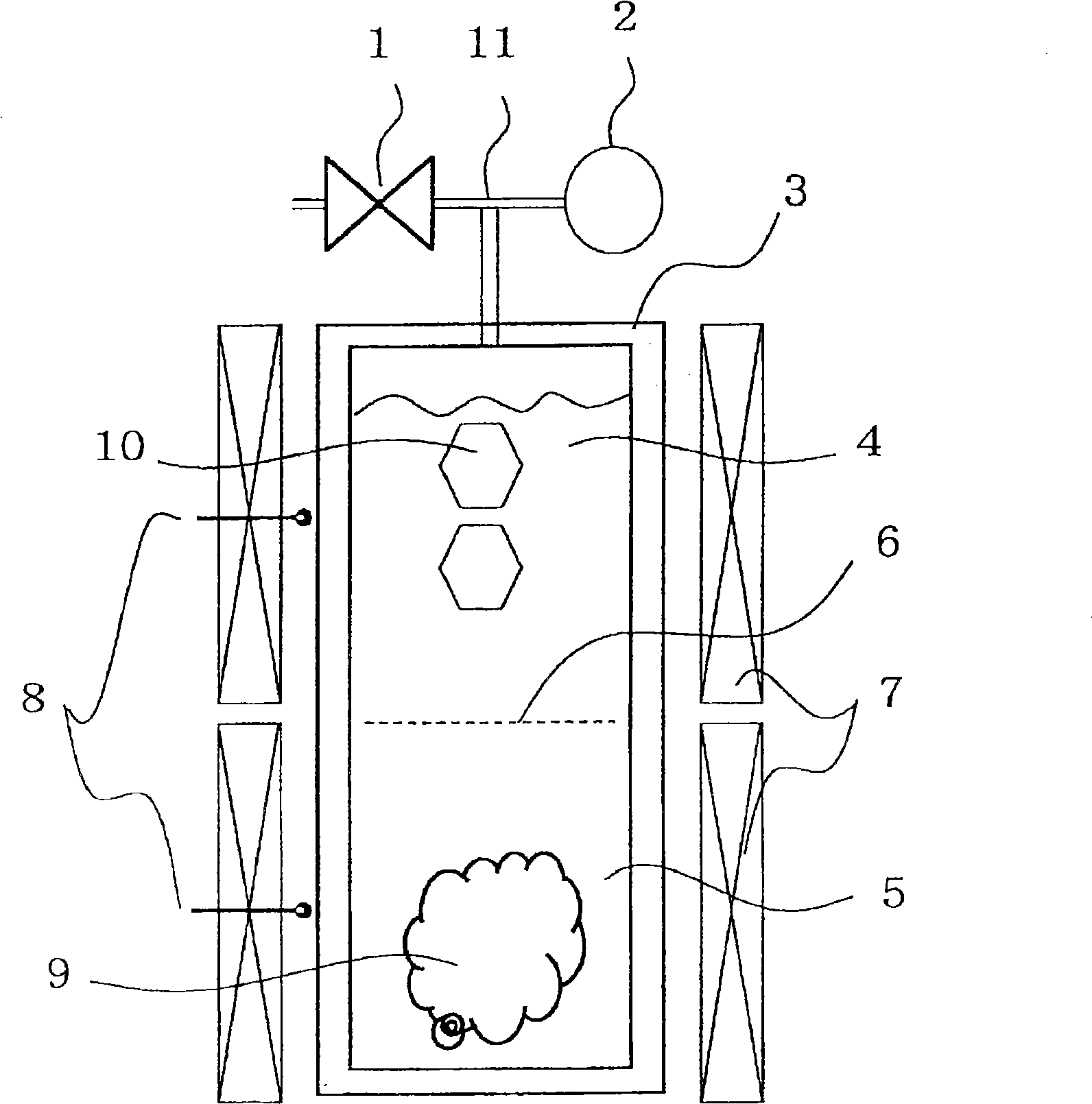

[0126] use figure 2 The shown setup was used for crystal growth.

[0127] Using a platinum-lined autoclave 3 (manufactured by Incone 1625, about 30 ml) with an internal size of 16 mm in diameter and 160 mm in length, 7.4 g of GaN polycrystals produced by HVPE were charged as a raw material 9 into the raw material filling part 5 of the autoclave, and then Filled with fully dried powdered NH 4 Cl (purity 99.99%) 1.57g was used as a mineralizer.

[0128] Next, the baffle 6 was placed at a position 80 mm from the bottom, and GaN seed crystals were placed on the crystal growth portion 4 thereon, and the lid of the autoclave equipped with a valve was quickly closed, and then the measurement of the autoclave 3 was performed. The GaN seed crystal 10 used here has a thickness of 50 μm in the c-axis direction, a C-plane of 5 mm square, and one of the sides becomes an M-plane by cleavage. Next, the operation is to connect the conduit 11 to the vacuum pump through the valve 1 attached...

Embodiment 2~7、 comparative example 1~2

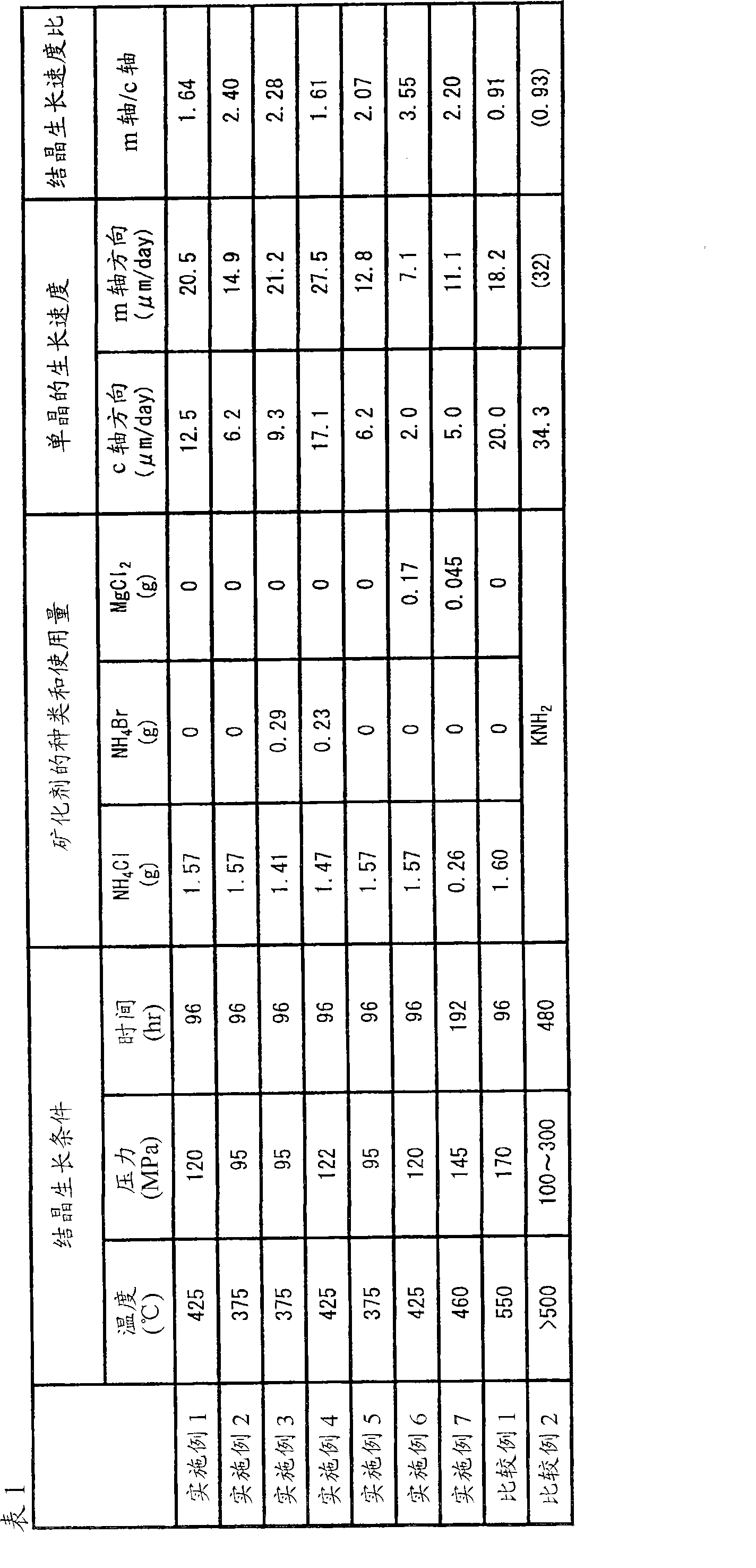

[0132]Except changing the crystal growth conditions of Example 1 and the type and usage amount of the mineralizer as shown in Table 1, the growth of GaN crystals was attempted in the same manner as in Example 1 (Examples 2 to 4, 6, 7 and Comparative Example 1). In Example 5, growth of a GaN crystal was attempted in the same manner as in Example 2, except that a seed crystal having an M-plane produced by slicing instead of cleavage was used. Comparative Example 2 is a technique described in a known document (Journal of Crystal Crowth 287 (2006) 376-380).

[0133] In Examples 2 to 7, the GaN crystal grown on the surface of the seed crystal was taken out and the state of the crystal surface was observed with a SEM (scanning electron microscope). As a result, as in Example 1, no needle crystals and grains were observed. The result of X-ray diffraction measurement is that the crystal shape is hexagonal, and the crystal growth orientation is the same as that of the seed crystal, or...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com