Method and device for utilizing flying ash in electric power plant to produce floating beads

A technology of fly ash and floating beads, which is applied in the field of producing floating beads by using fly ash of power plants, can solve the problems of low coal ash utilization level and unreachable utilization rate, and achieve good market application prospects and industrialization prospects , short payback period and small investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

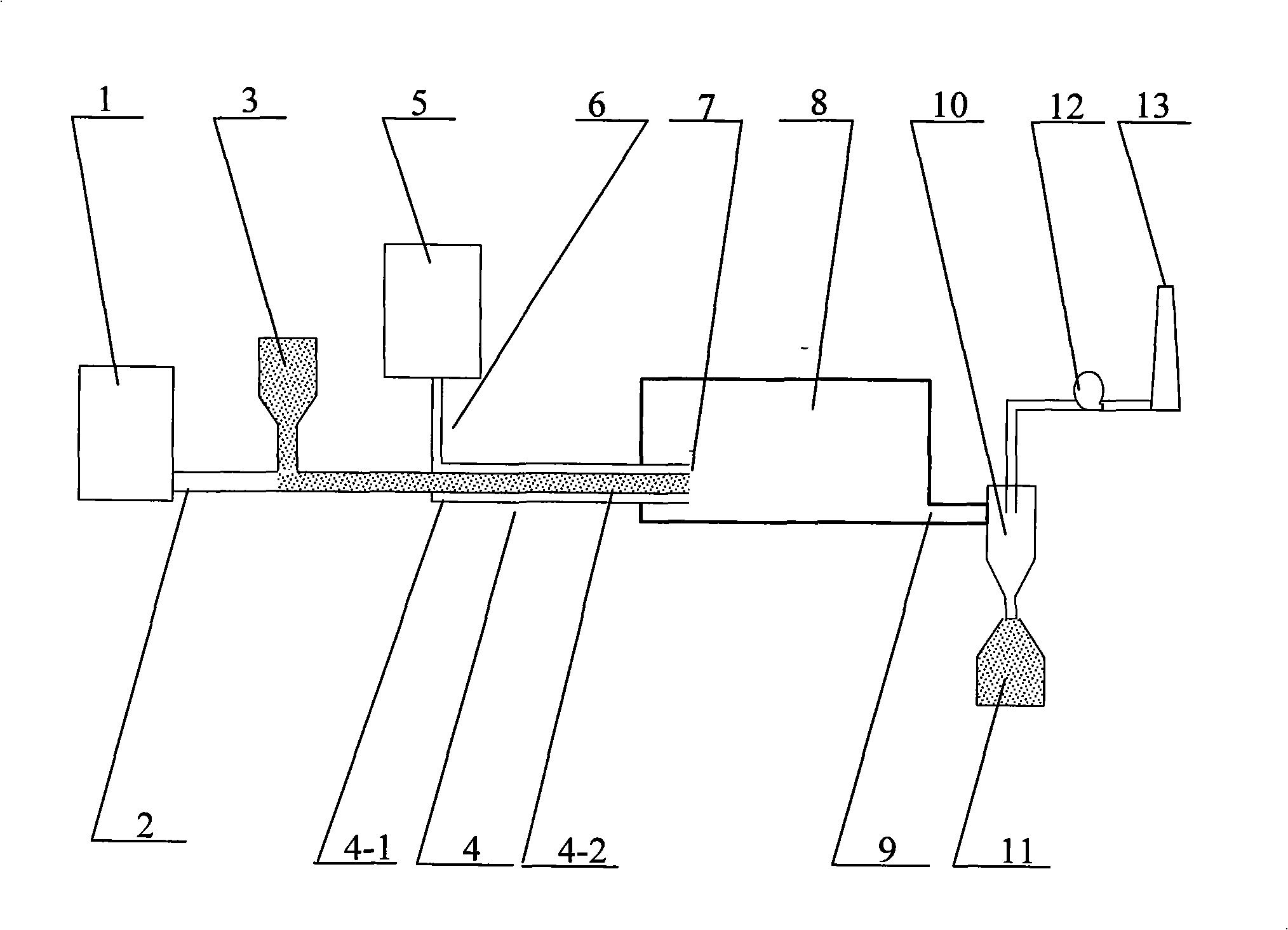

[0018] The equipment for producing drift beads by using fly ash in power plants is composed of fuel gas tanks, fly ash bins, nozzles, small air separation machines, combustion chambers, gas-solid separators, and exhaust gas discharge outlets. The fly ash produced by the combustion of the power plant with a particle size of less than 200μ is placed in the fly ash bin 3, and the fuel gas in the fuel gas tank 1, such as methane or acetylene, enters the nozzle 4 through the fuel gas inlet 2, and carries the fly ash through the outlet of the nozzle 7 into the combustion chamber 8. The nozzle 4 consists of concentric tubes, the inner tube 4-2 is the feed tube for fuel gas and fly ash. The outer tube 4-1 is an air inlet for pure oxygen. The pure oxygen produced by the small air separation machine 5 enters the nozzle through the inlet 6 of pure oxygen, and also enters the combustion chamber through the outlet 7 of the nozzle. The fuel gas and pure oxygen are mixed and burned in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com