Plate blank tundish for preventing cast-on downward flow and preparation method thereof

A tundish and slab technology, which is applied in the field of slab tundish and its preparation, can solve the problems of downflow of the tundish, heavy scouring, slag falling off of the lining of the tundish cover, etc. The effect of consumption of refractory and prevention of steel penetration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

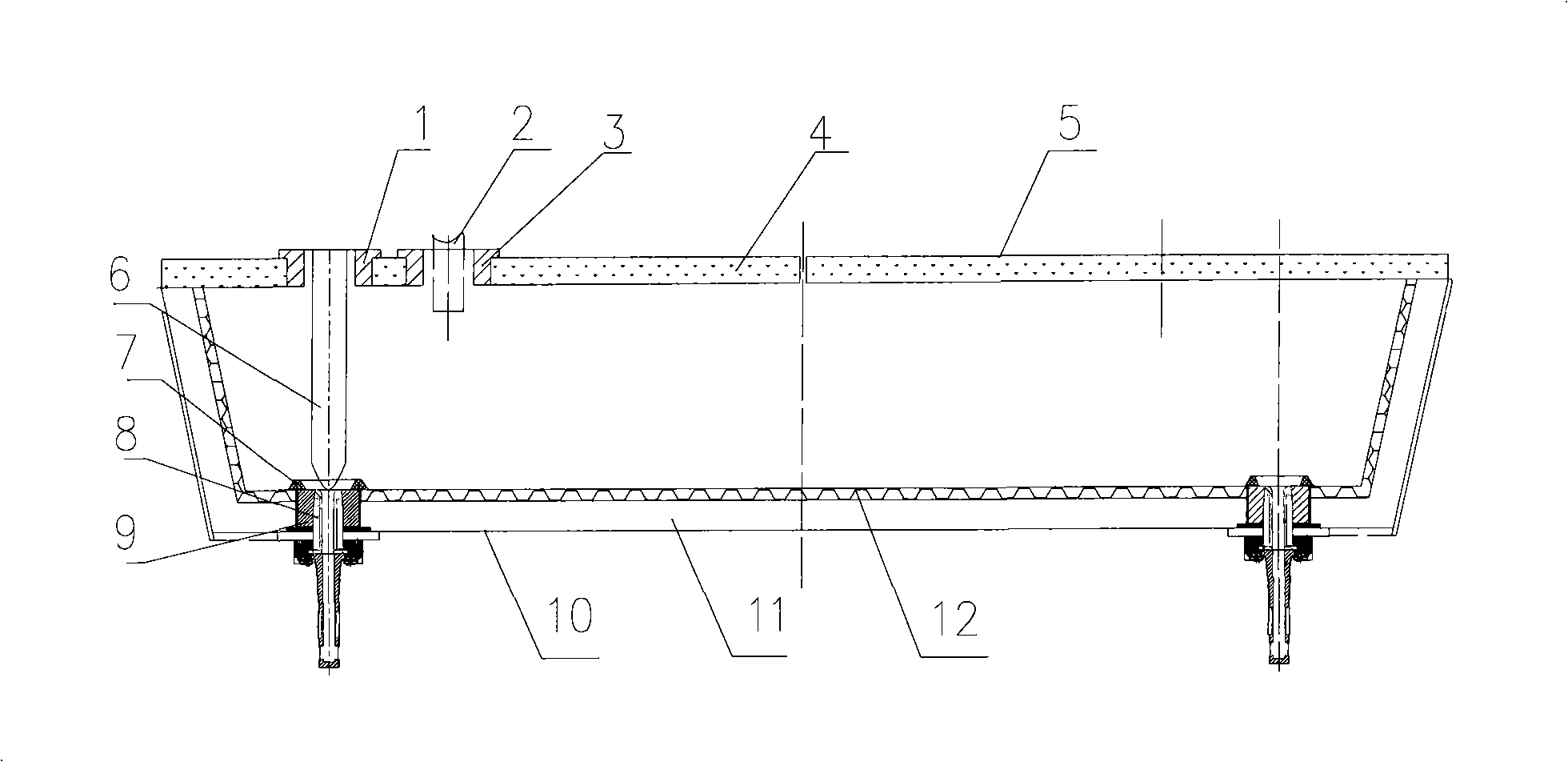

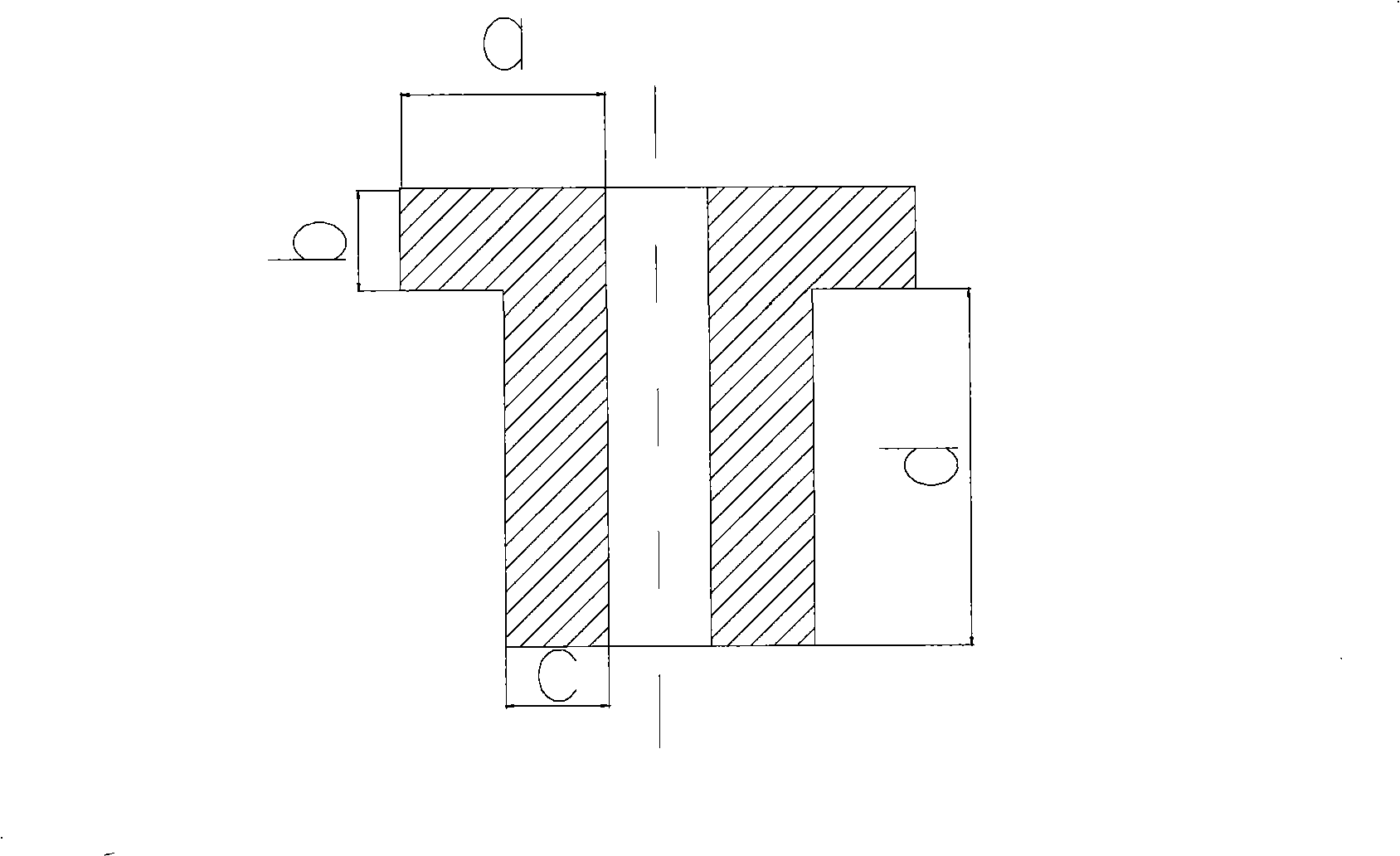

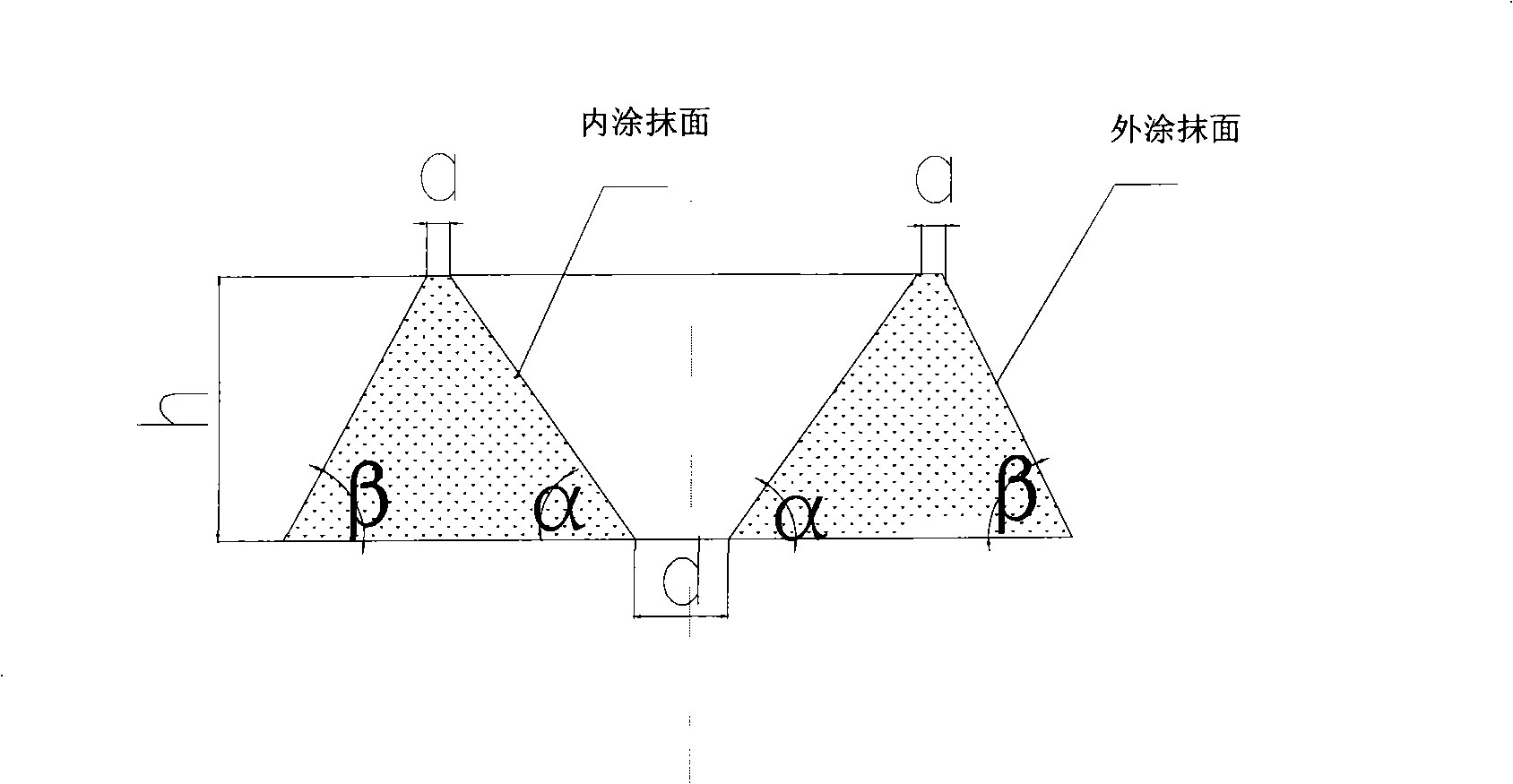

[0039] A slab tundish for preventing open pouring, comprising a shell 10, a permanent lining 11, a working lining 12, an upper nozzle 8, an upper nozzle seat brick 9, an upper nozzle cofferdam 7, a cover 5, and a cover inner lining for pouring Material 4, stopper rod installation hole prefabrication 1, roaster burner installation hole prefabrication 3, stopper 6, roaster burner 2, the inner side of the shell 10 is the permanent lining 11, and the outer side of the permanent lining 11 is the working lining 12 , the upper nozzle block 9 is located in the bottom permanent lining 11 and the working lining 12, the upper nozzle 8 is installed in the upper nozzle block 9, the upper nozzle cofferdam 7 is located on the upper surface of the nozzle block 9, and the cover 5 is placed in the cladding 10, the inner side of the cover 5 is the cover lining castable 4, the stopper 6 passes through the stopper 6 on the cover 5 and the prefabricated part 1 is positioned at the steel connection p...

Embodiment 2

[0058] A slab tundish for preventing open pouring, comprising a shell 10, a permanent lining 11, a working lining 12, an upper nozzle 8, an upper nozzle seat brick 9, an upper nozzle cofferdam 7, a cover 5, and a cover inner lining for pouring Material 4, stopper rod installation hole prefabrication 1, roaster burner installation hole prefabrication 3, stopper 6, roaster burner 2, the inner side of the shell 10 is the permanent lining 11, and the outer side of the permanent lining 11 is the working lining 12 , the upper nozzle block 9 is located in the bottom permanent lining 11 and the working lining 12, the upper nozzle 8 is installed in the upper nozzle block 9, the upper nozzle cofferdam 7 is located on the upper surface of the nozzle block 9, and the cover 5 is placed in the cladding 10, the inner side of the cover 5 is the cover lining castable 4, the stopper 6 passes through the stopper 6 on the cover 5 and the prefabricated part 1 is positioned at the steel connection p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com