Air finishing machine

An air conditioning and rack technology, which is used in dryers, progressive dryers, textile materials processing, etc., can solve the problems of wasting fabrics, manpower, and raw materials, and achieves uniform smoothness and reduced The effect of labor cost and production cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

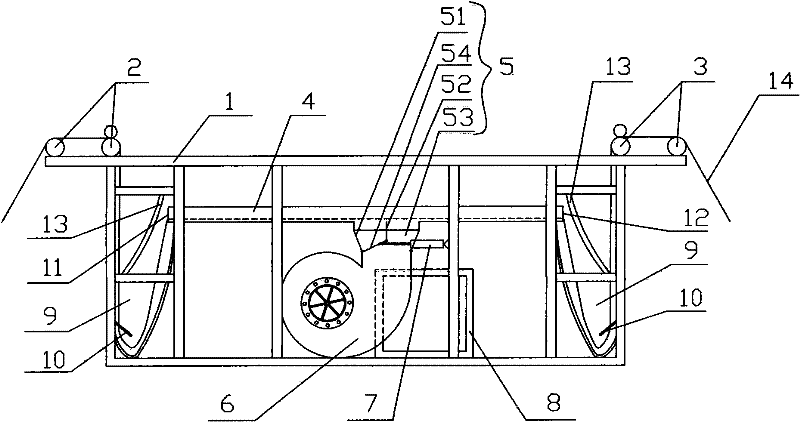

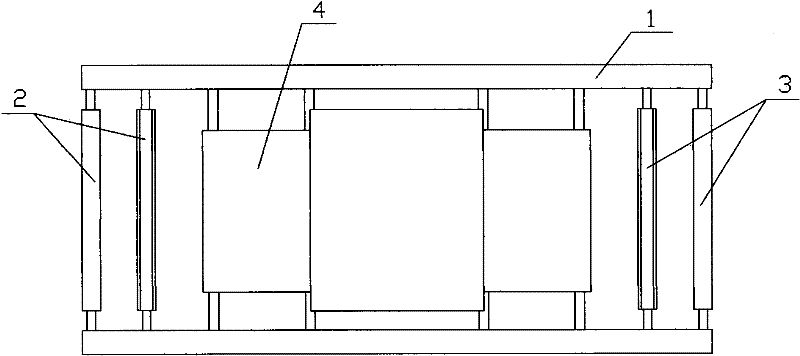

[0021] Embodiment 1: refer to figure 1 , figure 2 As shown, it is a preferred embodiment of the present invention, a kind of air finishing machine, comprising a frame 1, positioned at the top of the frame 1 and cloth feeding rollers 2 and cloth discharging rollers 3 are respectively installed on the left and right sides of the frame. An air duct 4 for fabric 14 to pass is installed in the frame 1, and a tuyere box 5 is communicated in the middle of the air duct 4, and the air inlet of the tuyere box 5 communicates with the air outlet of the blower 6, and the tuyere box 5 includes a box body 51, a partition 52 is arranged in the box body 51, and two air inlet passages 53 are formed in the box body 51 through the partition board 52, and one end of the partition board 52 is hinged to be used for closing one of the air inlet passages. 53 of the movable wind plate 54, the movable wind plate 54 is connected with the cylinder 7, the work of the cylinder 7 can swing the movable wind...

Embodiment 2

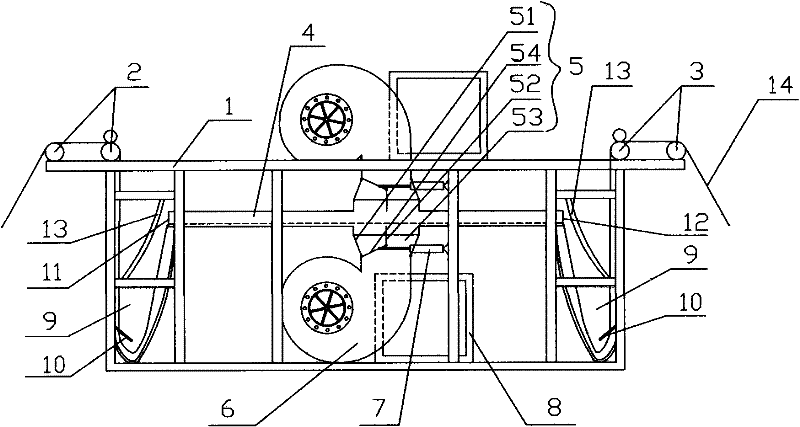

[0023] Embodiment 2: refer to image 3 As shown, it is another preferred embodiment of the present invention. The difference between this embodiment and Embodiment 1 is that there is a tuyere box 5 in the middle of the air duct 4 and connected to the upper and lower sides, each The air nozzle box 5 is connected with blower 6 and cylinder 7 independently, and on the air inlet that is positioned at blower 6 on frame 1, also all is equipped with cooling box 8. When in use, the wind force produced by the upper and lower blowers 6 can act on the fabric 14 in the air duct 4 simultaneously according to the requirements of the fabric 14, so that the fabric 14 moves back and forth faster and more efficiently. The rest of this embodiment is the same as that of Embodiment 1, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com