Experimental apparatus for testing sliding friction property of friction materials

An experimental device, sliding friction technology, applied in the direction of measuring device, analyzing materials, using mechanical devices, etc., can solve the problem of not specifically measuring the sliding friction properties of friction materials, and achieve the effect of wide loading range, high work efficiency and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

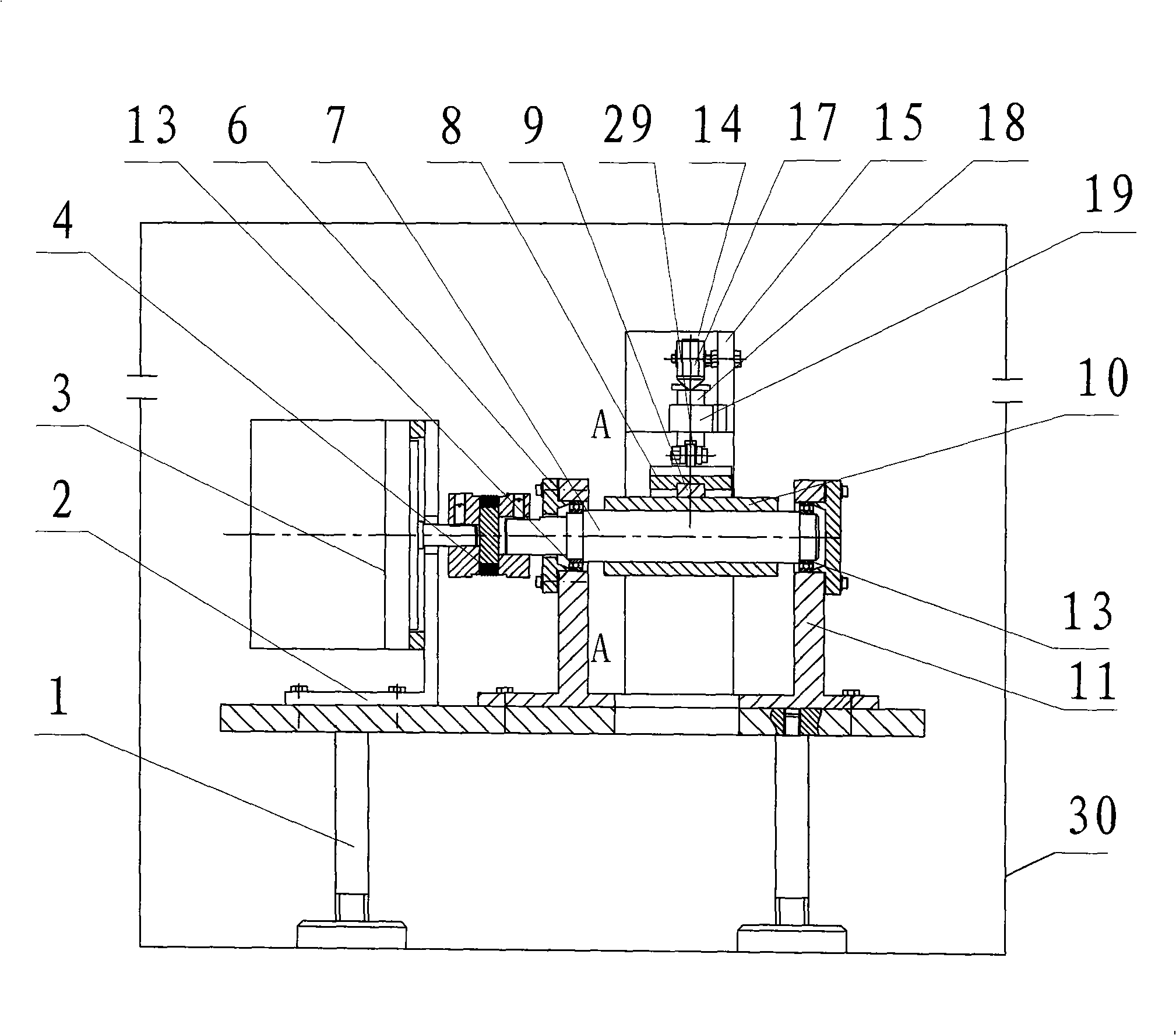

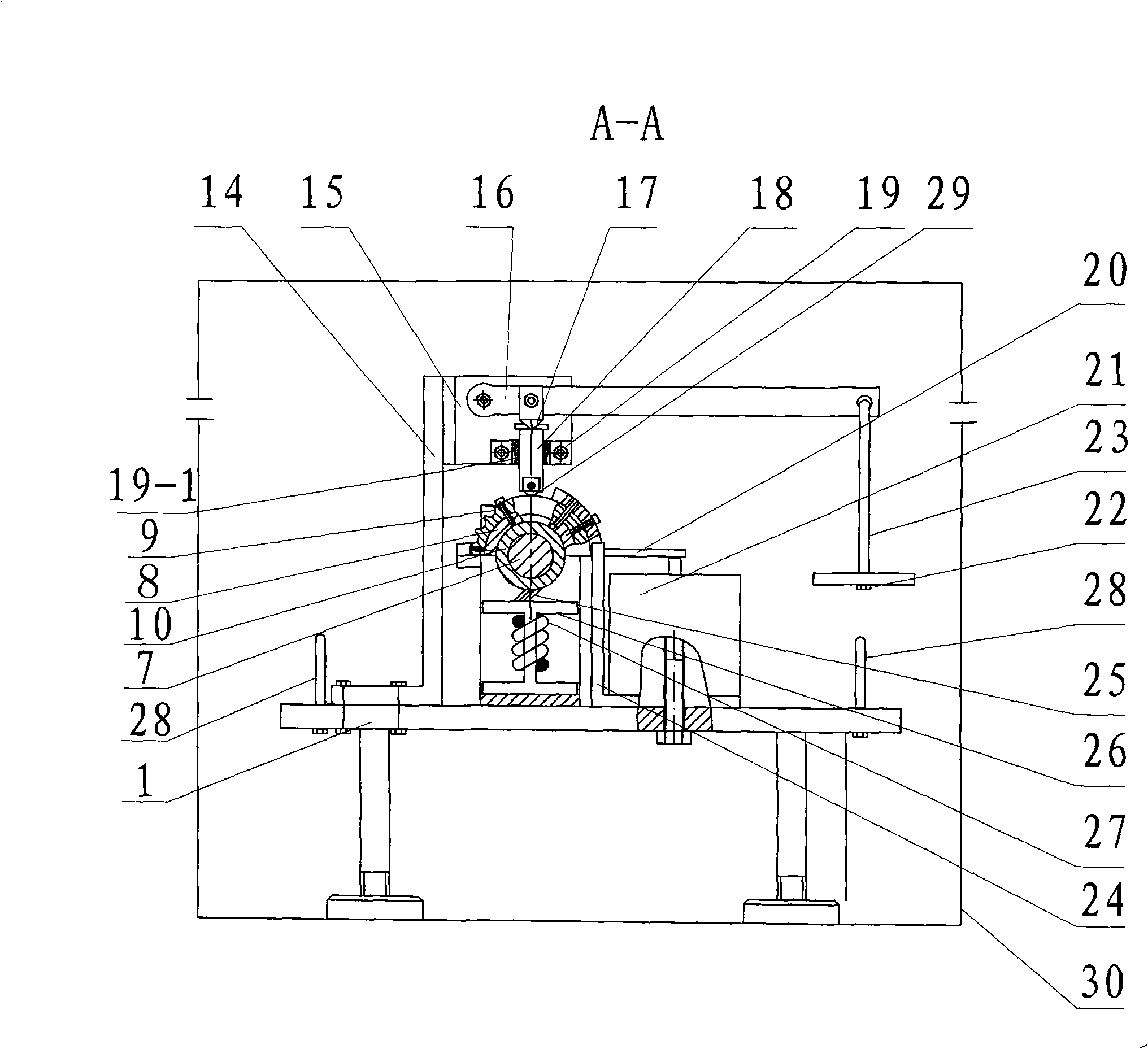

[0007] Specific implementation mode one: as Figure 1~2 As shown, the experimental device for testing the sliding friction performance of friction materials described in this embodiment is composed of a base 1, a transmission device, a loading device, a measuring device and a refrigeration device. The transmission device includes a motor support 2, a motor 3, an elastic coupling Shaft device 4, main shaft 7, axle sleeve 10, bearing block 11 and two bearings 13; Loading device comprises loading bracket 14, loading support plate 15, lever 16, loading pressure bar 17, loading shaft 18, pressure bar bearing 19, Weight plate 22 and connecting rod 23; Described measuring device is made up of bearing bush 8, bearing bush seat 9, sensor pressure bar 20, pressure sensor 21 and sensor support 24; Described refrigeration device comprises copper brush 25, copper brush support 26 and liquid Nitrogen spiral copper tube 27; the motor 3 is affixed to the upper end surface of the base 1 throug...

specific Embodiment approach 2

[0008] Specific implementation mode two: as figure 1 As shown, the motor 3 in this embodiment is a rare earth permanent magnet DC torque motor. Rare earth permanent magnet DC torque motor has the advantages of low speed, large torque and strong overload capacity; compared with DC brush torque motor, it has the advantages of simple structure, high reliability of motor body and maintenance-free. Other components and connections are the same as those in the first embodiment.

specific Embodiment approach 3

[0009] Specific implementation mode three: as figure 2 As shown, the loading compression rod 17 in this embodiment divides the moment arm length ratio of the lever 16 into 1:8. In this way, the weight of the weight can be magnified eight times by the lever 16, and then transmitted to the friction member through the loading pressure rod 17 and the loading shaft 18, so as to load the friction test and facilitate data calculation. Other compositions and connections are the same as those in Embodiment 1 or 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com