Reinforcement frame for a display panel using extruded aluminum alloy and apparatus and method for manufacturing the same

A technology of aluminum alloy and display panel, which is applied in the direction of manufacturing tools, metal processing equipment, instruments, etc., can solve the problems of long welding cycle, increased manufacturing cost, difficulty in maintaining connection strength, etc., and achieves the effect of facilitating welding operation and reducing welding time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The above objects of the present invention are achieved by adopting aluminum alloy rolled parts and a rotational friction welding method.

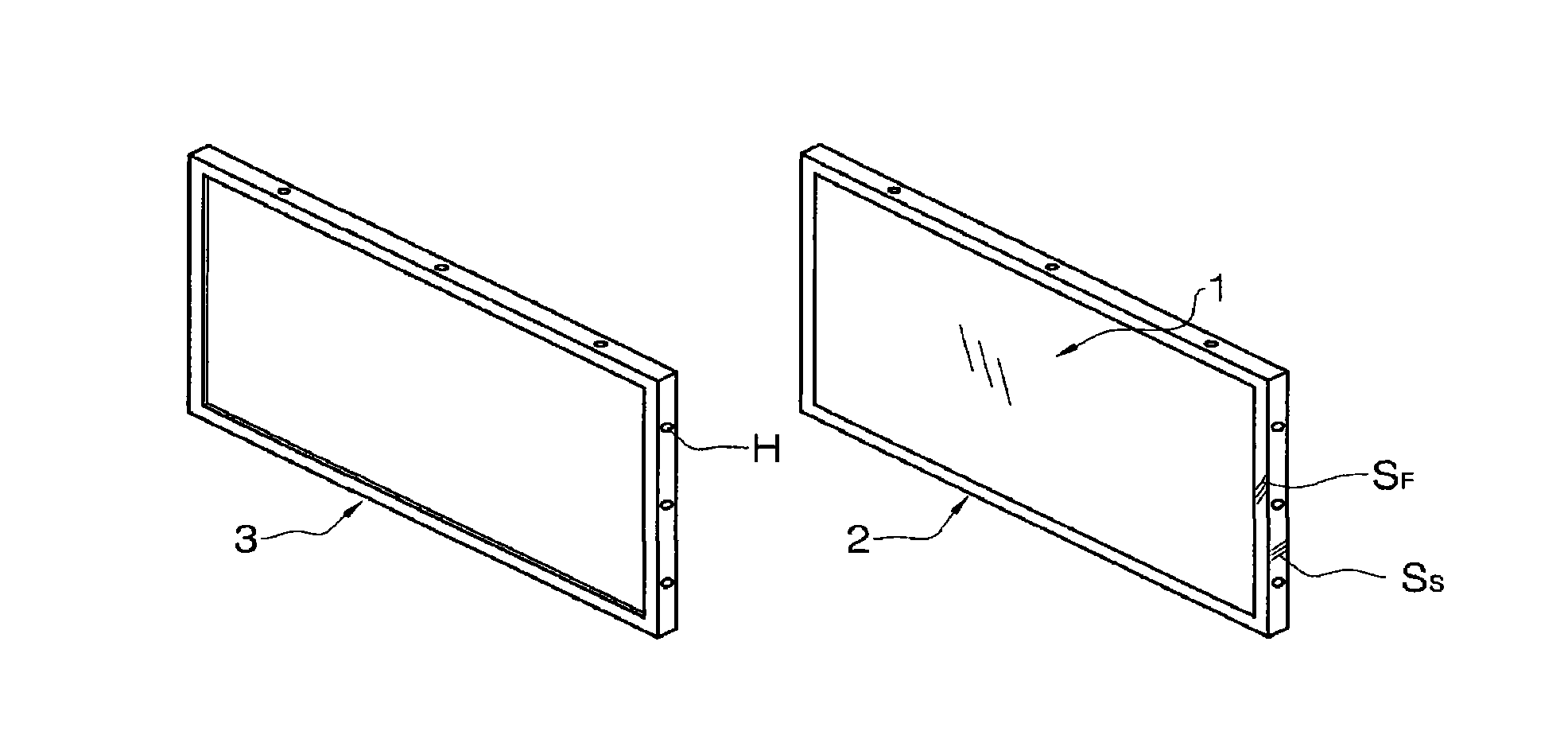

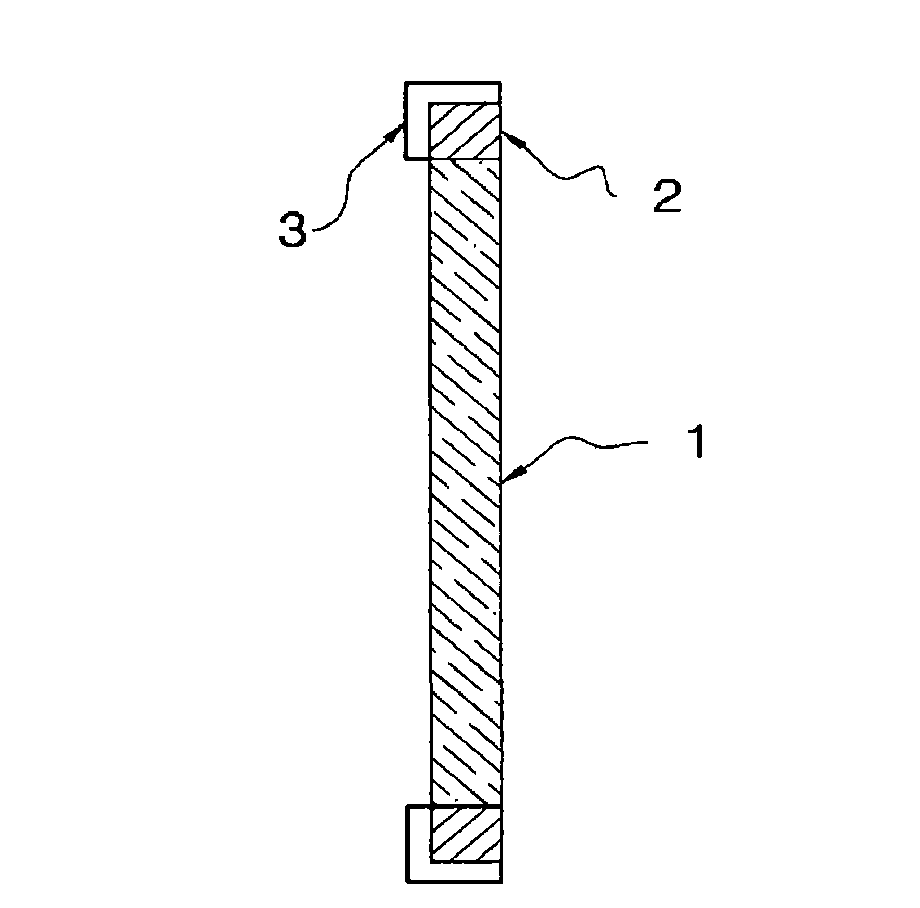

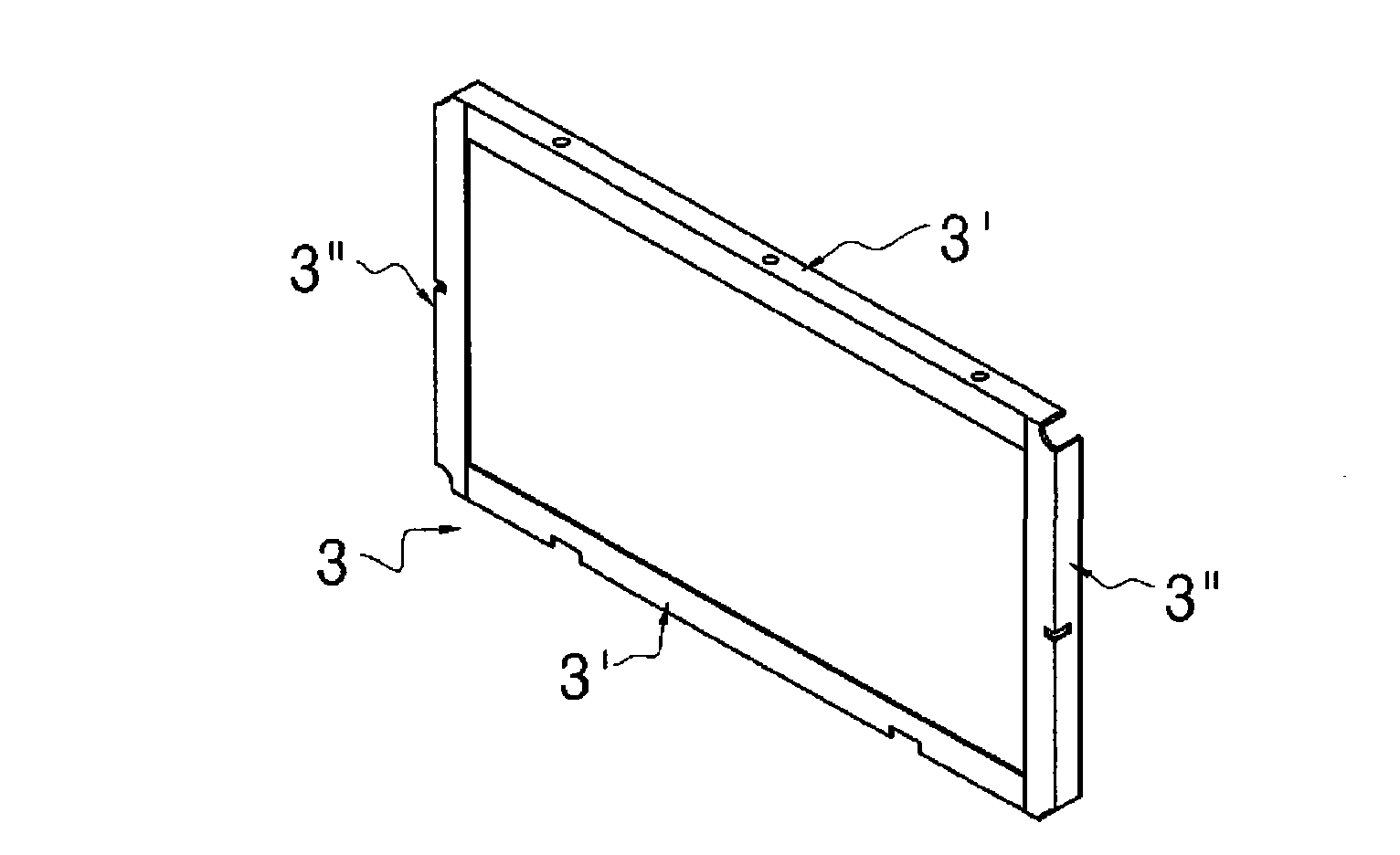

[0044] A reinforced frame using aluminum alloy rolled parts for an LCD panel according to the present invention is obtained by rolling four frame parts so as to obtain an L-shaped section, cutting these parts to a suitable length, and then closely connecting these parts to each other into a square shape frame shape. The technical feature is that the corresponding ends of the frame parts are brought into contact, and the four corners are joined by a rotational friction welding method.

[0045]The aluminum alloys used to reinforce the frame according to the invention are wrought aluminum, the most widely acceptable classification of which is as follows: 1000 series are pure aluminum with an aluminum content of at least 99.00 wt %; 2000 series are aluminum copper alloys; 3000 series are aluminum manganese alloys; 4000 series is alumin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com