Automatic type detonation-hindered flame arrester

A flame arrester, an automatic technology, applied in the field of fire arresting devices, can solve the problems of air supply resistance, less obvious energy loss, and increased energy loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Specific embodiments of the present invention will be described in detail below in conjunction with technical solutions and accompanying drawings.

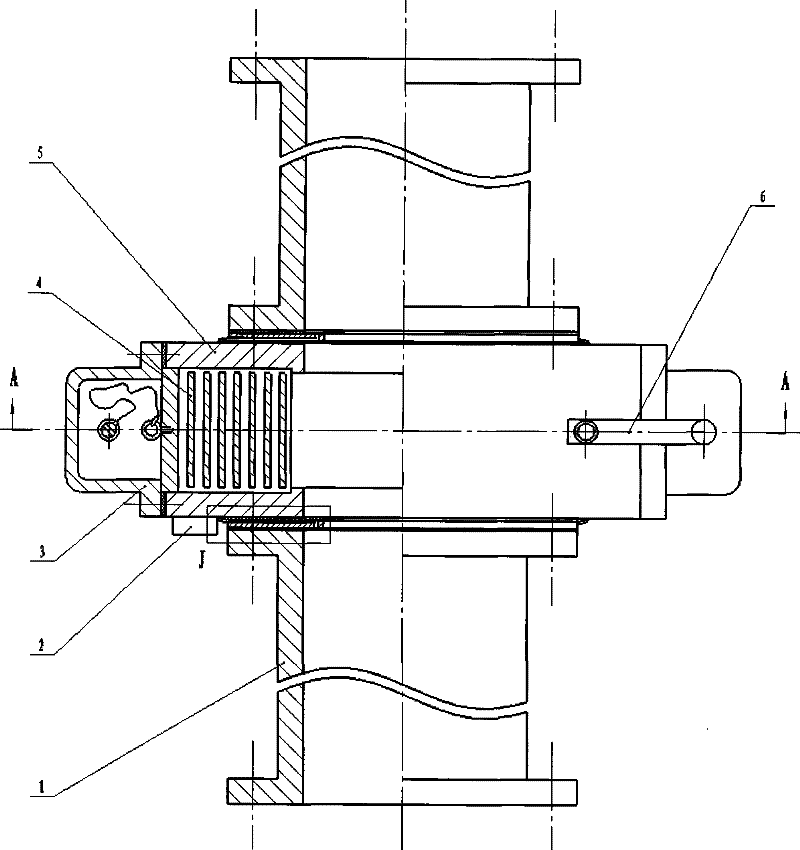

[0023] Embodiment Taking the manual reset mechanism as an example, the flame arrester housing, cover and fire arresting core are made of aluminum.

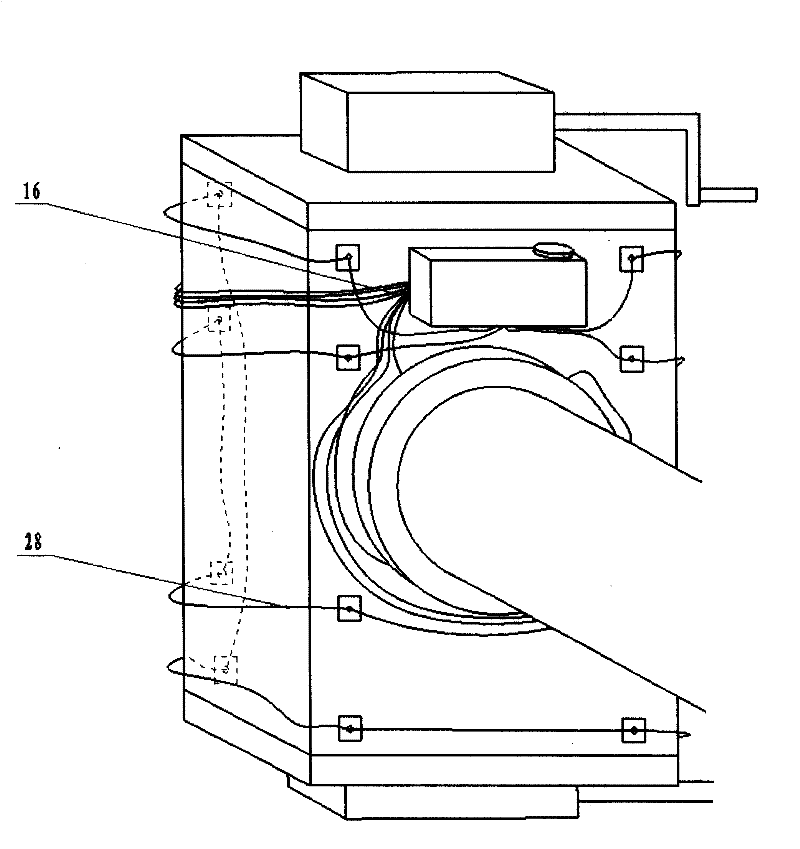

[0024] figure 1 The state shown is that the flame arresting core 4 stagnates on both sides of the pipeline under normal conditions.

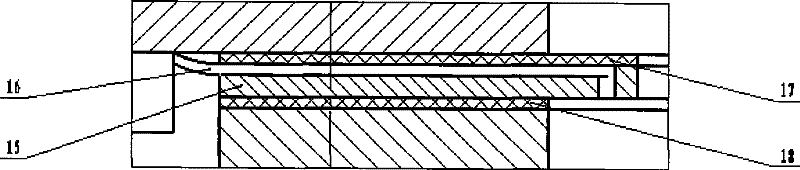

[0025] figure 2 Among them, the optical fiber 16 is fixed in the metal gasket 15, and is sealed with the upper sealing gasket 17, and one side is photosensitive and the other side is exported and introduced into the electric control mold box 2.

[0026] When there is a flame in the pipeline, the photosensitive element 10 receives the light signal and transmits it to the electric control module 2 through the optical fiber 16, and is converted into an electrical signal through the electric control module 2; 4 pops up, closes the pipeline along ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com