Mold releasing laminated film

A technology of laminating film and demoulding, applied in the direction of layered products, synthetic resin layered products, chemical instruments and methods, etc., can solve the problems of loss of film stiffness, thermal adhesion of stainless steel plates, poor operability, etc. Interlayer peeling, excellent mold release, and economical effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

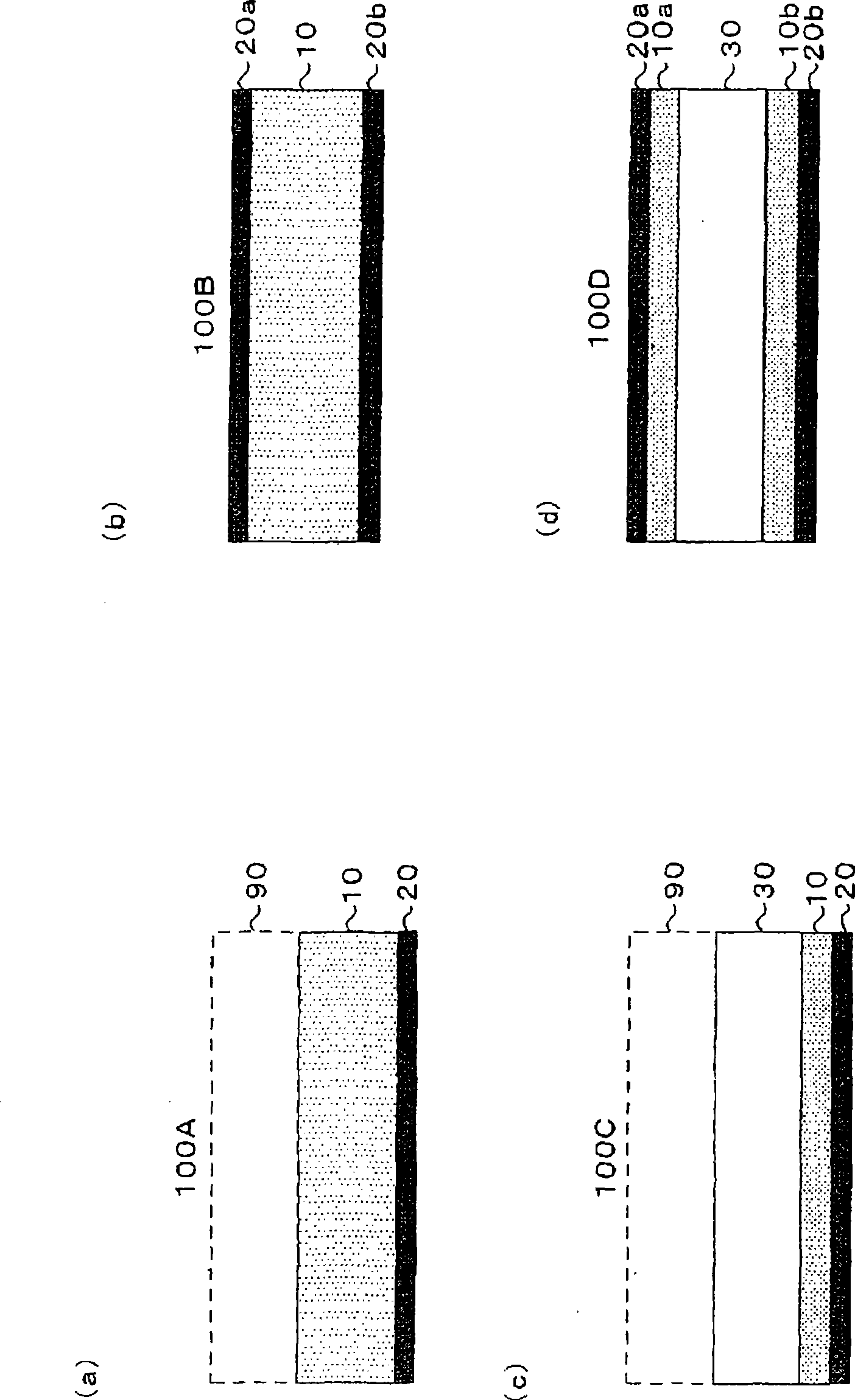

[0065] figure 1 The layer constitution of the laminated film for mold release of this invention is shown. Such as figure 1 As shown in (a), the release laminate film 100A of the present invention has a layer 10 made of a modified polyolefin resin and a layer 20 made of an adhesive fluororesin laminated on at least one side of the layer.

[0066] The so-called "adhesive fluororesin" in the present invention refers to the following fluororesin: Lexpal R A3150 (Nippon Polyethylene Co., Ltd. system) and fluororesin in 4×10 5 ~5×10 5 Under the sample pressure of Pa, pressurize at 240°C for 10 minutes to produce a laminated sheet, cut the sample obtained by cutting it into a width of 2.5cm and a length of 25cm, and adopt a method based on JIS Z0237 at a peeling speed of 5mm / min and a temperature of The 180 degree peel strength at the time of measurement of 180 degree peel strength at 23 degreeC is 4 N / cm or more.

[0067] In addition, the IR spectrum of the "adhesive fluororesi...

no. 2 approach

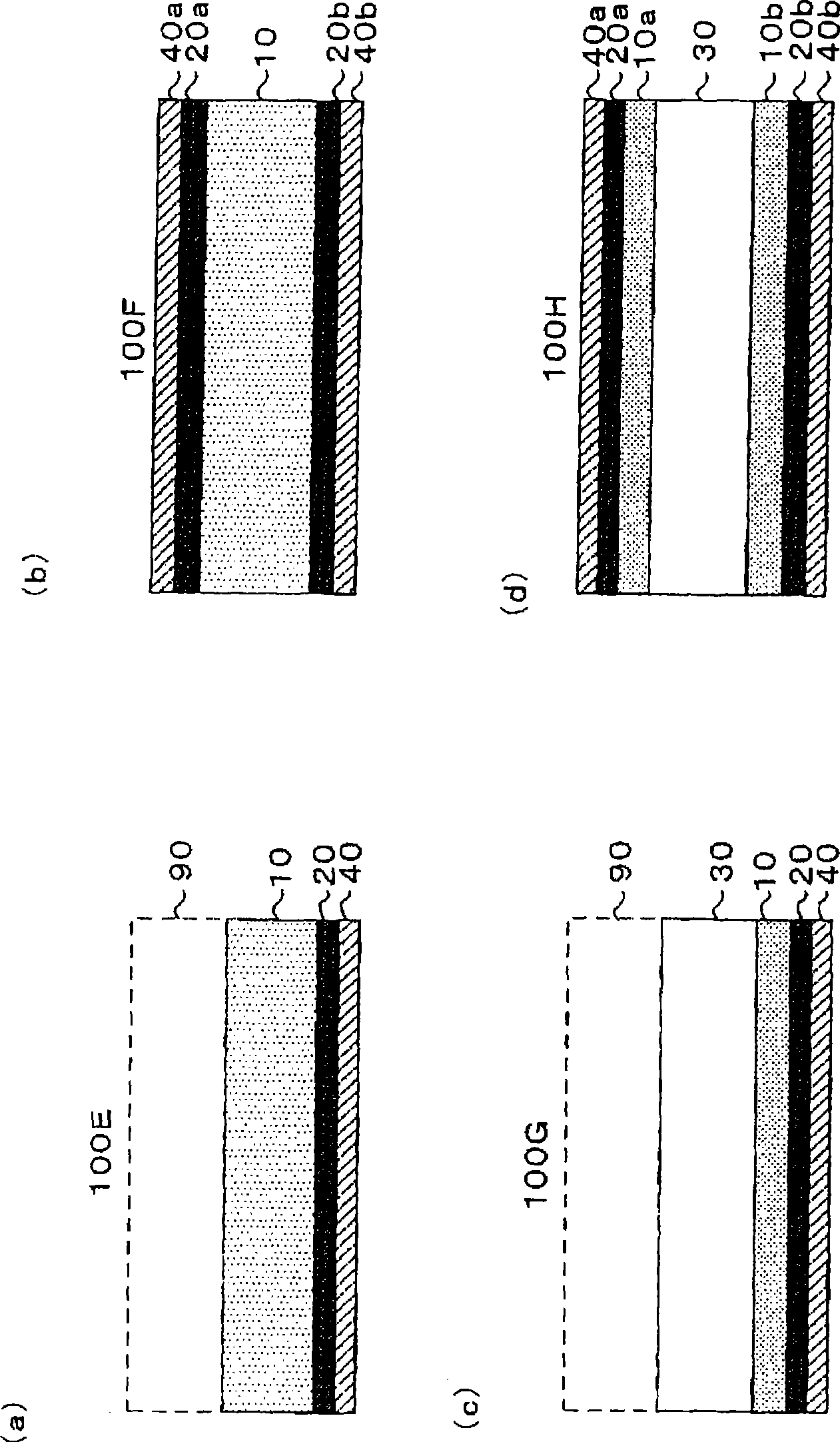

[0089] The mold release laminated film 100 of the present invention can have a structure including a layer made of a heat-resistant resin and a layer made of a fluororesin laminated on at least one side of the layer. The invention according to the second embodiment is particularly a release laminate film that can be used very suitably even in a high-temperature environment.

[0090] Further, several layers may be further laminated as necessary on the surface opposite to the surface on which the layer made of fluororesin is laminated among the layers made of heat-resistant resin. Among them, it is preferable to laminate a layer made of a fluororesin on both sides of a layer made of a heat-resistant resin in view of exhibiting releasability on both sides and being excellent in economical efficiency.

[0091] Here, the thickness of the layer made of fluororesin is preferably 1 to 15 μm, and the thickness of the layer made of heat-resistant resin is preferably 10 to 150 μm. With ...

no. 3 approach

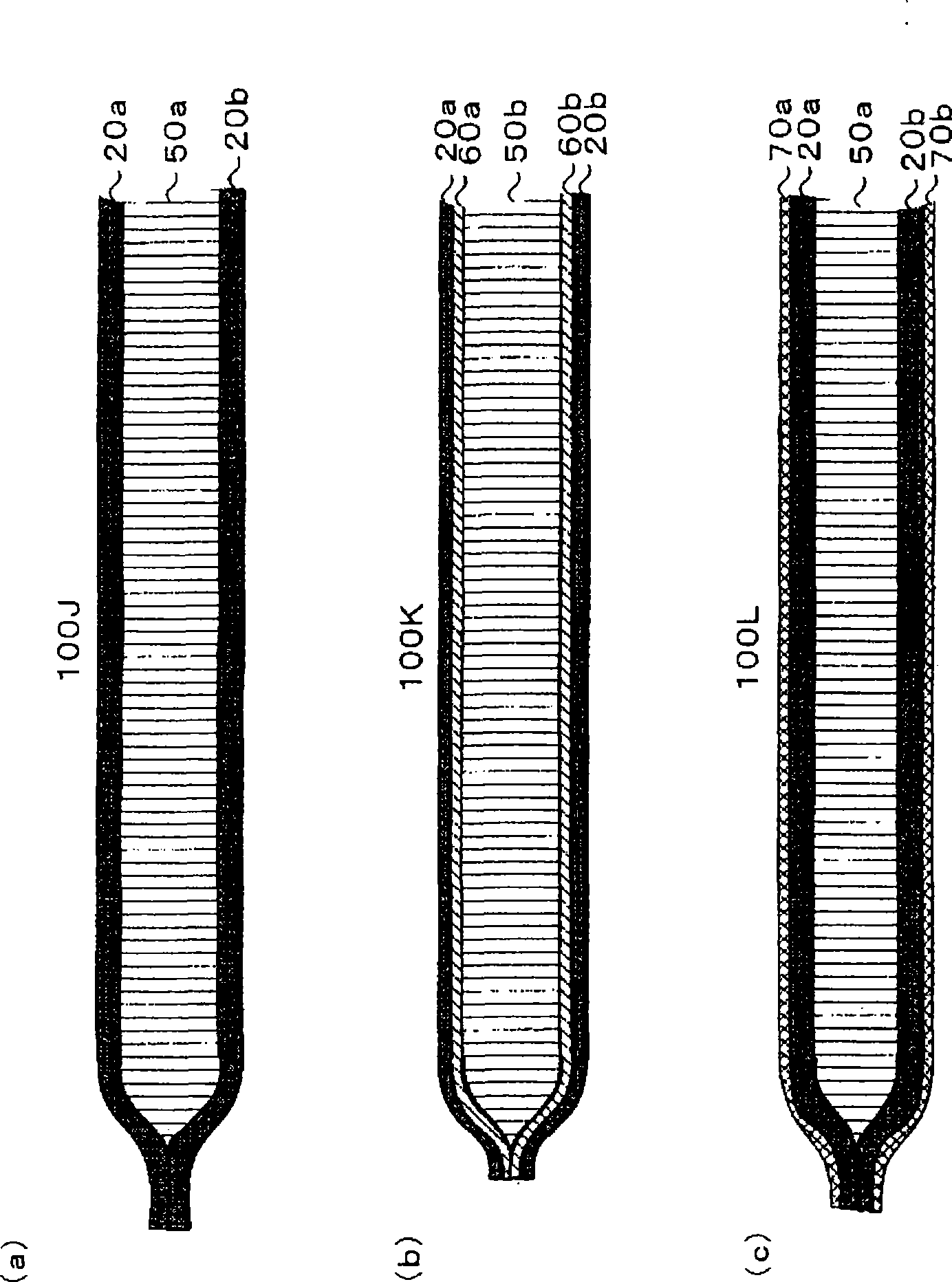

[0099] image 3 (a) is a cross-sectional view in the thickness direction showing the layer constitution of the release laminate film 100J according to the third embodiment of the present invention. The illustrated laminated film 100J has a three-layer structure, and layers 20a and 20b made of adhesive fluororesin are arranged on both sides of a core layer 50a. In this embodiment, the resin constituting the core layer 50a must be a resin having a melting point lower than that of the adhesive fluororesin. With such a configuration, only the resin constituting the core layer 50a can be melted by heating during press molding, and it is possible to easily follow the stepped shape of the multilayer substrate during press molding. At the end of the laminated film 100J, such as image 3 (a) As shown on the left, it is preferable to adopt a structure in which two layers of adhesive fluororesin layers 20a and 20b are directly bonded to seal the core layer 50a, but since the laminated ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com