Method for treating printing and dyeing wastewater

A technology for printing and dyeing wastewater and treatment methods, which is applied in textile industry wastewater treatment, neutralized water/sewage treatment, oxidized water/sewage treatment, etc., can solve problems such as poor treatment effect, and achieve the effect of solving high treatment costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

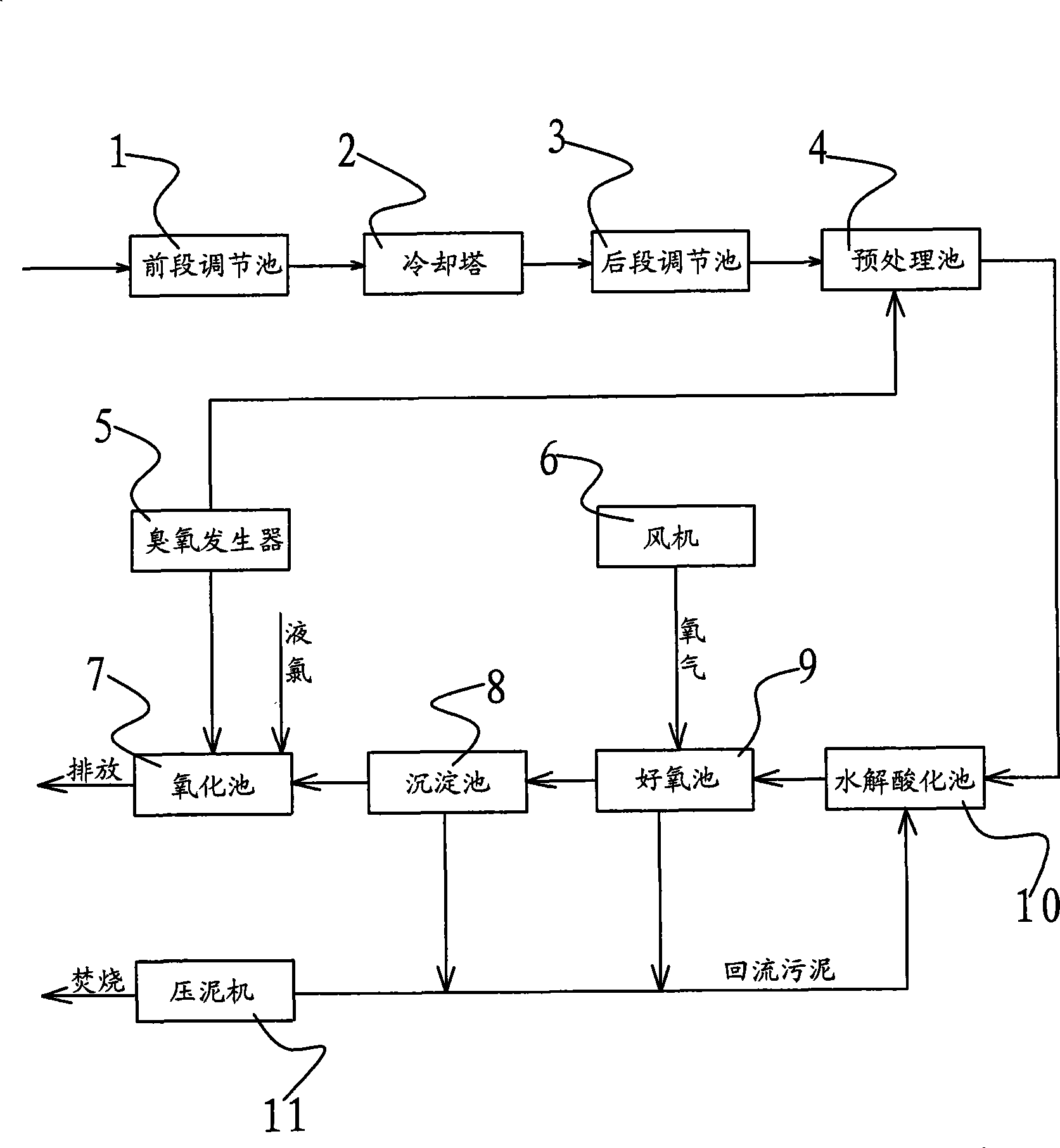

Image

Examples

Embodiment 1

[0028] at 10,000 m 3 Take the treatment of printing and dyeing wastewater per day as an example, using ozone and biochemical combined process for treatment:

[0029] The printing and dyeing wastewater (40°C-45°C) in the workshop is first pre-regulated by the pretreatment system, the water temperature of the printing and dyeing wastewater can be reduced to about 30°C-35°C, the pH is adjusted to 8-9, and the water volume is adjusted to 42m 3 / Hour.

[0030]The printing and dyeing wastewater regulated by the pretreatment system enters the pretreatment pool 4, and some reducing substances that are easier to be oxidized are first oxidized. In the pretreatment tank 4, the dosage of ozone is 10g / m 3 Wastewater, the contact time is about 20 minutes, the ozone gas is in reverse contact with the printing and dyeing wastewater, the biodegradability of the treated printing and dyeing wastewater is increased to about 0.4 (about 0.23 before ozone oxidation treatment), and the chroma of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com