A high-temperature exhaust pipe primer and finish

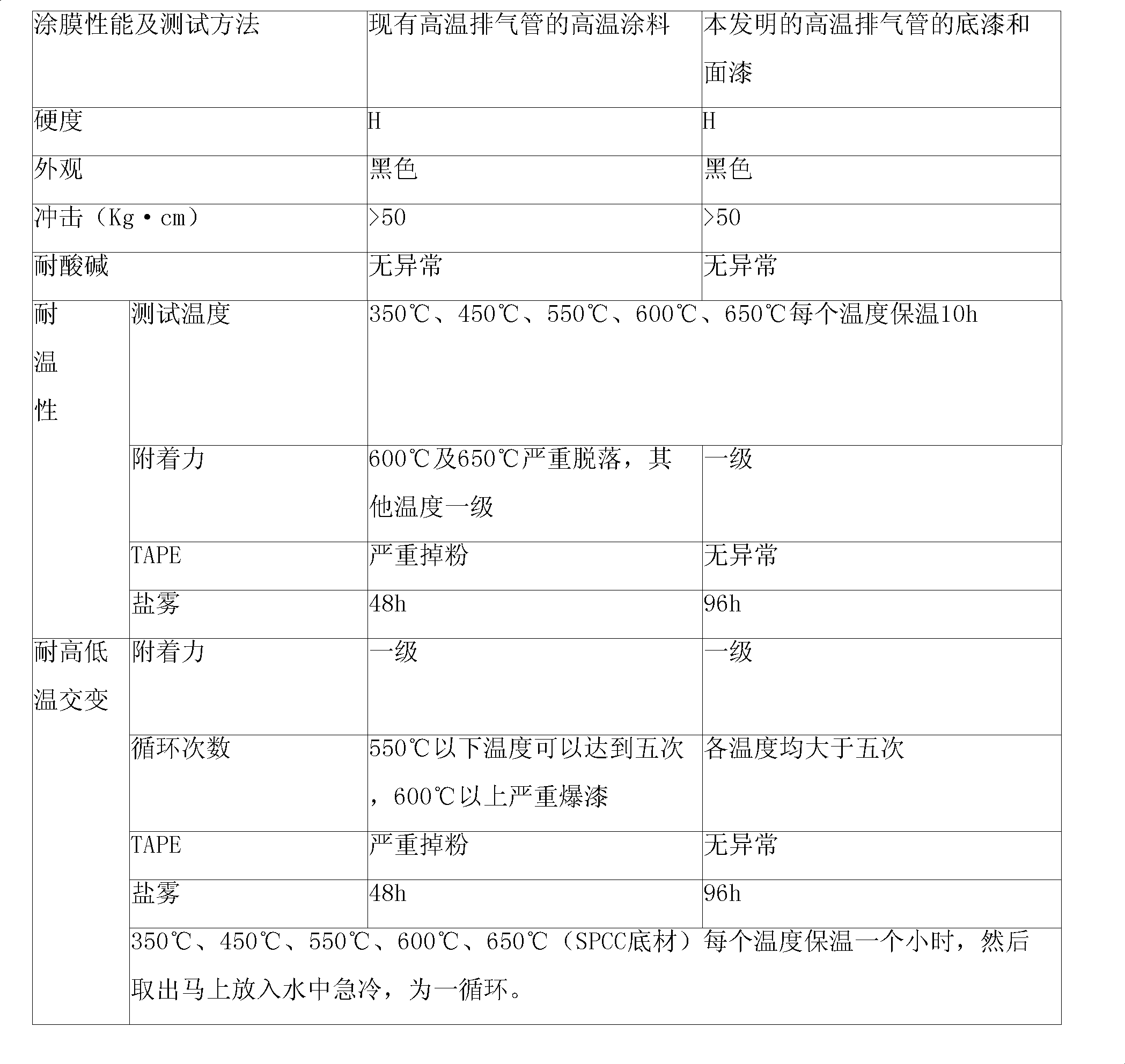

An exhaust pipe, high temperature technology, applied in the coating and other directions, can solve the problems of easy cracking of the coating film, poor high and low temperature alternating resistance, poor salt spray resistance, etc., and achieve the effect of not easy cracking and good temperature resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] A primer for high-temperature exhaust pipes of the present invention comprises the following components: epoxy-modified silicone resin, epoxy resin, filler, ferrochrome black powder, anti-settling agent and solvent. The above-mentioned epoxy-modified silicone resin is the main resin, and the epoxy resin is the modified resin, which helps to improve the anti-corrosion performance of the primer. The filler includes talcum powder, ceramic powder and mica, and the above-mentioned filler is helpful for secondary film formation and further improves anticorrosion performance.

[0015] The content of each component is: 10-30% of epoxy modified silicone resin, 1-5% of epoxy resin, 2-10% of talcum powder, 3-10% of ceramic powder, 3-10% of mica, chromium Iron black powder 1-2%, anti-settling agent 2-5%, solvent 20-30%.

[0016] The anti-sedimentation agent is fumed silica or bentonite, and the solvent is xylene or butyl ester, which help to prevent static delamination of the comp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com