Waterproof after finishing method for water-washable silk floss quilt

A waterproof finishing and post-finishing technology, used in fiber processing, textiles and papermaking, animal fibers, etc., can solve problems such as inability to process silk quilts, silk quilts with bulkiness, resilience, reduced softness, and no washability. , to achieve the effect of good application prospects, excellent ingestion, and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] A waterproof finishing method for a washable silk quilt, comprising the following steps:

[0022] (1) Configure waterproof finishing agent: the waterproof finishing agent includes 3% by weight of waterproof agent A, 1.2% of waterproof agent B, 1% of silk wool softener, 0.5% of silk wool bulking agent, and water; the waterproof Agent A is polymethyl hydrogen siloxane, and described waterproofing agent B is polydimethylsiloxane;

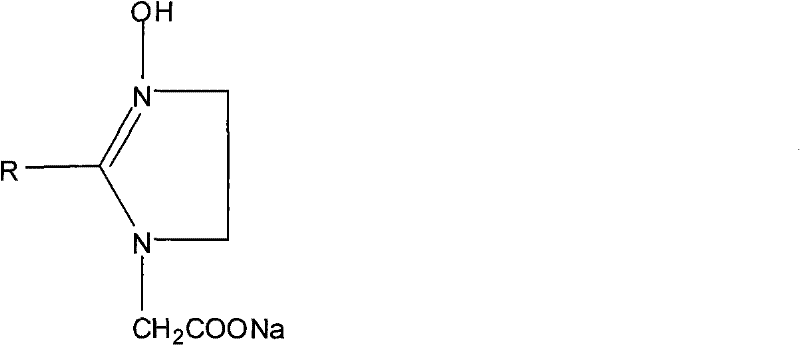

[0023] (2) The above-mentioned waterproof finishing agent is heated to 40°C, put into dry silk wool and soaked for 30 minutes, then, after the impregnated silk wool is dehydrated, pre-bake at 90°C for 5 minutes, and then bake at 160°C for 90 seconds ; Made into silk quilt by conventional methods. The silk wool softener in the step (1) is an amino-modified silicone softener; the silk wool bulking agent in the step (1) is an alkyl imidazoline derivative, and the structural formula is where R is C 17 of straight-chain alkyl groups.

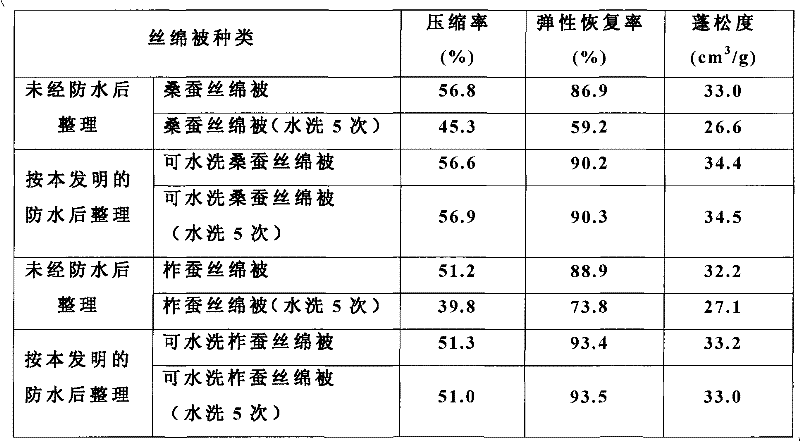

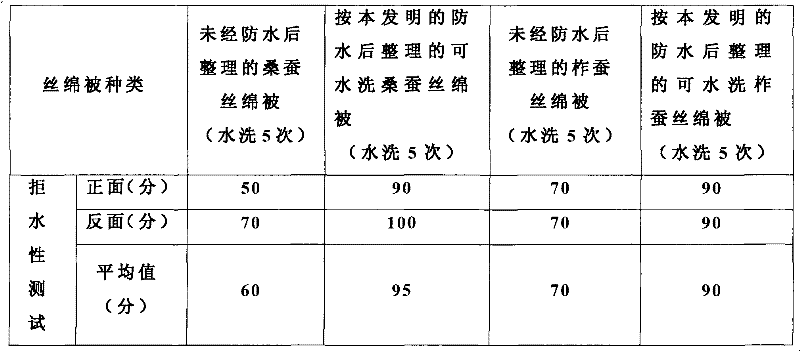

[0024] Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com