Method for detecting liquid height in stirred tank reactor

A detection method and technology of liquid level height, applied in the direction of liquid/fluid solid measurement, instruments, measuring devices, etc., can solve the real situation that the liquid level height of the reactor cannot be determined, the operating temperature cannot be applied, and the liquid level cannot be obtained, etc. , to achieve the effects of sensitive response, low requirements for measurement conditions, and small measurement errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

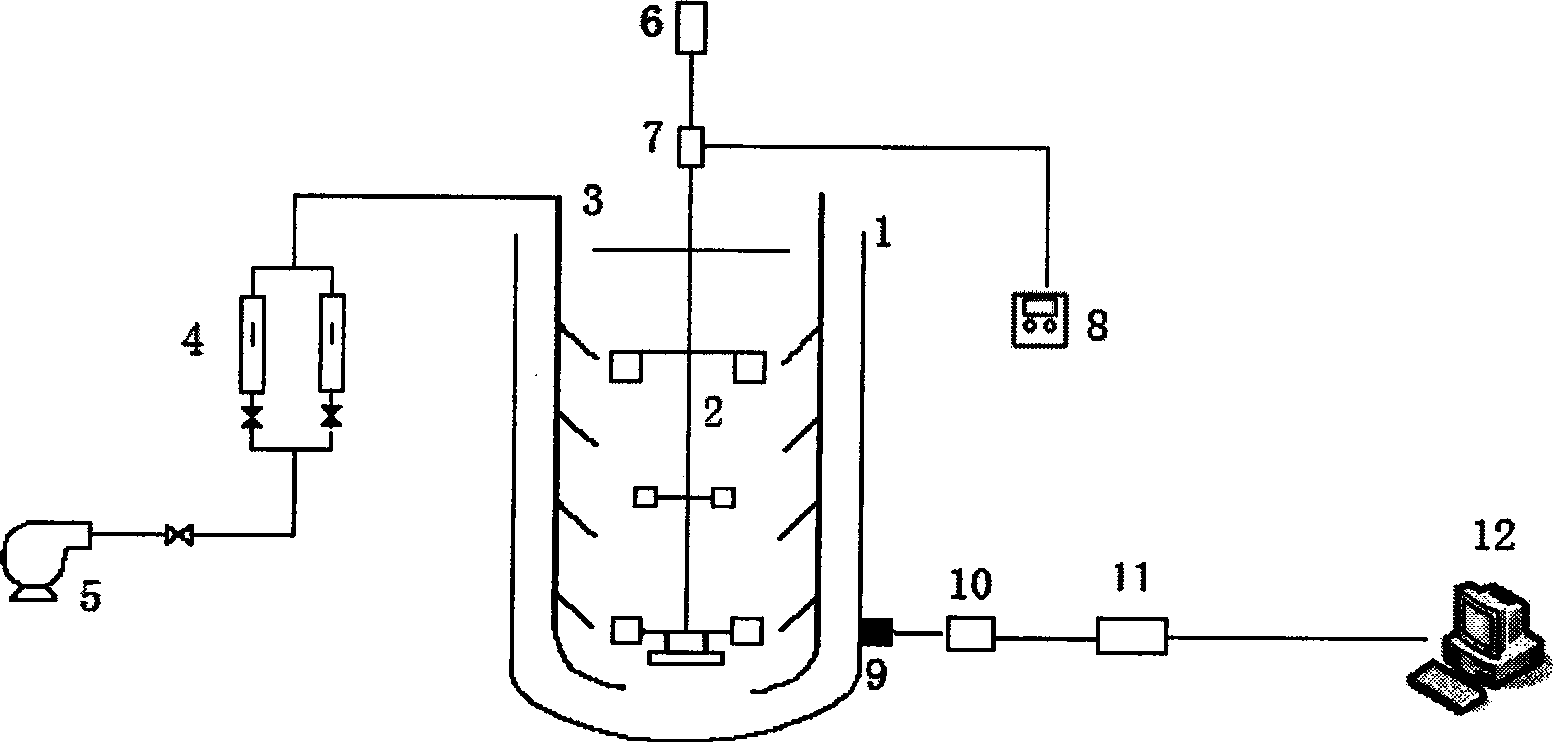

[0026] use as figure 1 The cold mold device shown includes a stirring tank 1, a stirring paddle 2, a finger-shaped baffle and an air intake pipe 3, a flow meter 4, a fan 5, a stirring motor 6, a torque sensor 7, a digital display instrument 8, and an acoustic emission signal receiving device 9 is set below the liquid level of the outer wall of the stirred tank 1, and connected to the computer 12 through the preamplifier 10 and the amplifier 11 in turn, and the signal acquisition card and corresponding software are installed in the computer 12.

[0027] The dynamic acoustic emission signal inside the reactor enters the amplification device through the acoustic emission receiving device 9 arranged on the outer wall of the kettle to amplify the signal to ensure the long-distance transmission of the signal, and then enters the acquisition card in the computer 12 for A / D of the signal converted, and finally processed and analyzed by computer 12.

[0028] The inner diameter of the ...

Embodiment 2

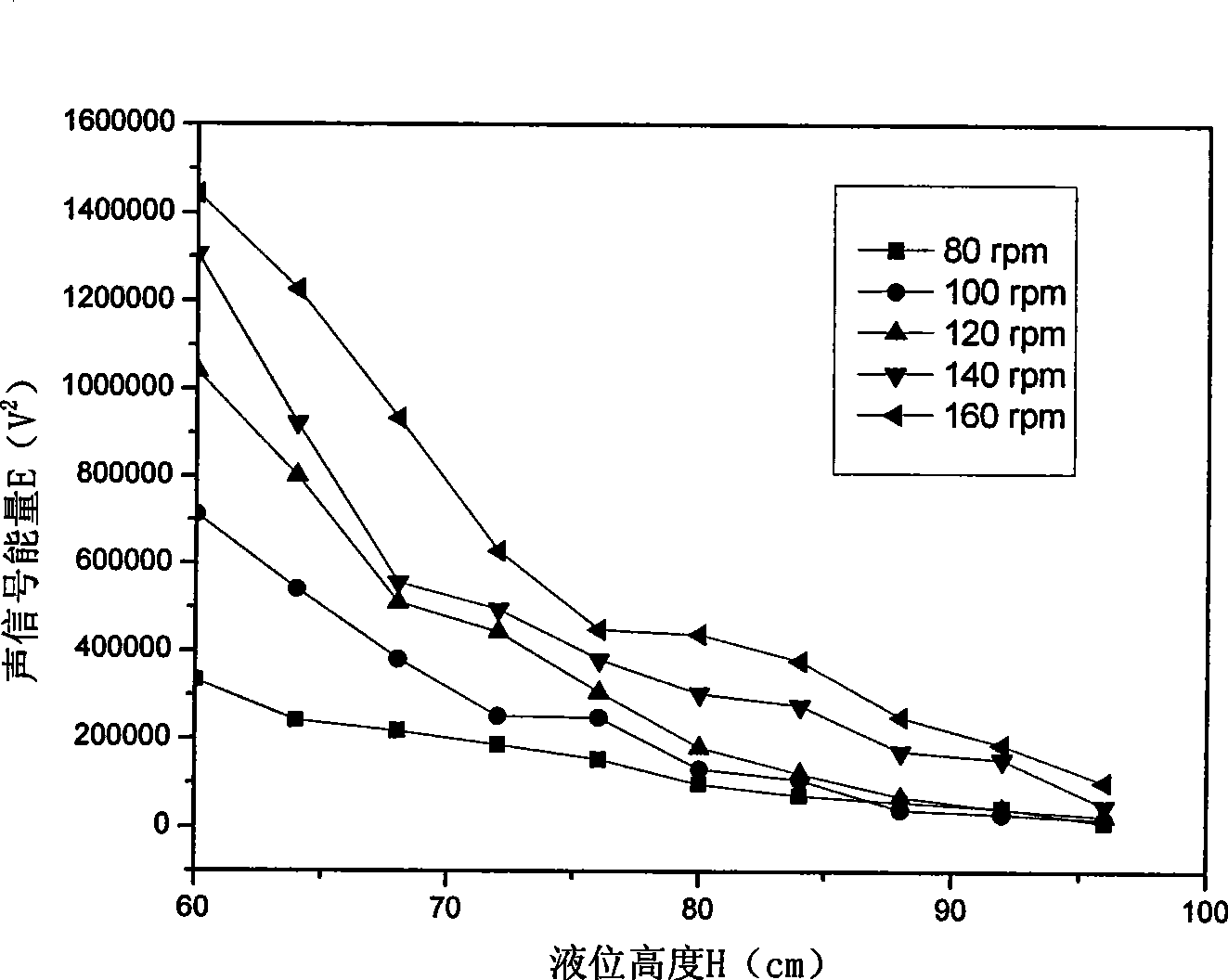

[0034] The method of the invention is used to detect the liquid level height of a certain pilot-scale polyethylene slurry stirring reactor. The speed adjustment range of the pilot reactor is 50-200r / min. The acoustic emission signal is measured with an acoustic wave measuring instrument. The acoustic wave measuring instrument includes an acoustic wave receiving device, an amplifying device, a signal collecting device and a signal processing device. The acoustic sensor is placed at the bottom of the reactor, the sampling frequency is 100MHz, and the sampling time is 5s.

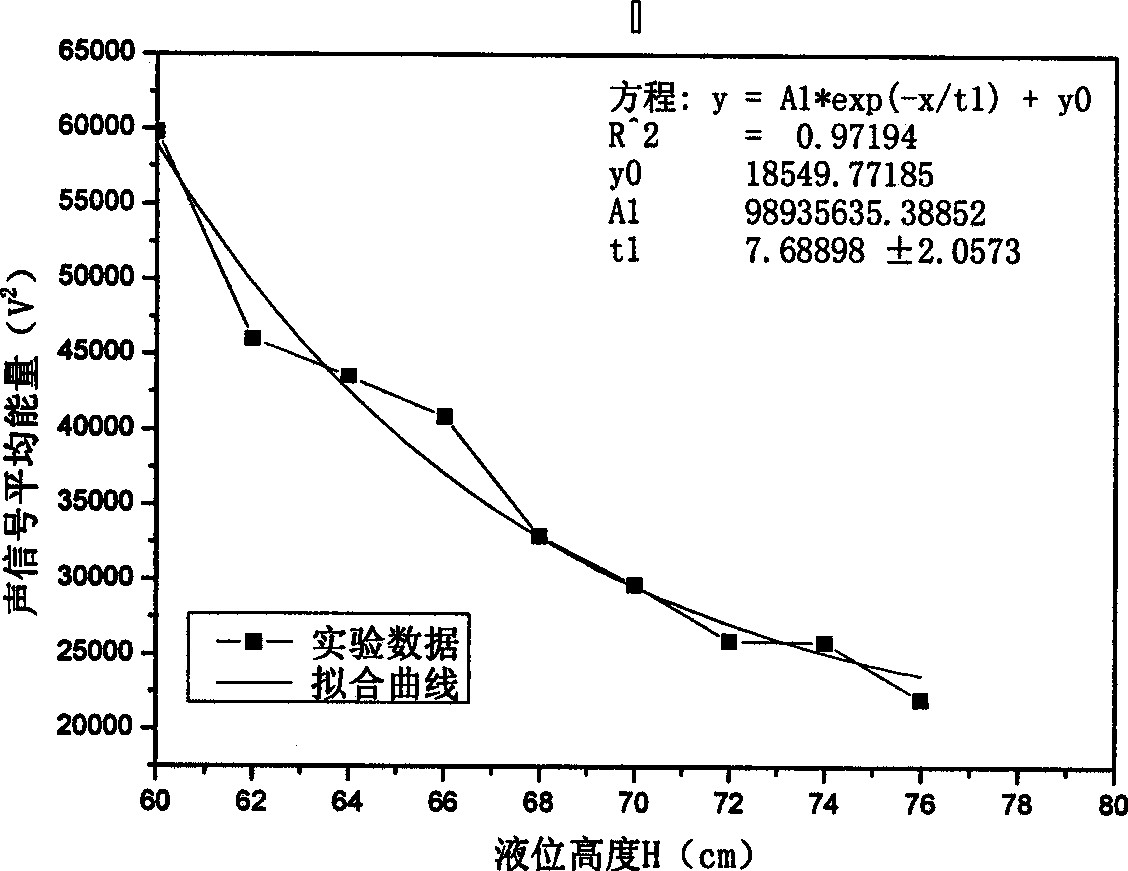

[0035] The medium used in the calibration experiment is water, and the liquid level in the kettle is changed by adding a known amount of water, and the acoustic emission signal is collected at the same time. The calibration experiment was carried out at five rotational speeds (80, 100, 120, 140, 160r / min), and the collected acoustic emission signal was transformed by FFT, and the average energy was obtained a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com