Wireless temperature measurement gun for metal solution and working method thereof

A technology of wireless temperature measurement and metal solution, which is applied to thermometers, thermometers, and measuring devices that use directly heat-sensitive electric/magnetic elements, and can solve the problem of measurement errors affecting the accuracy of temperature measurement and temperature measurement, easily damaged compensation wires, measurement Inaccurate accuracy and other problems, to achieve the effect of high measurement accuracy, extended use time, and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

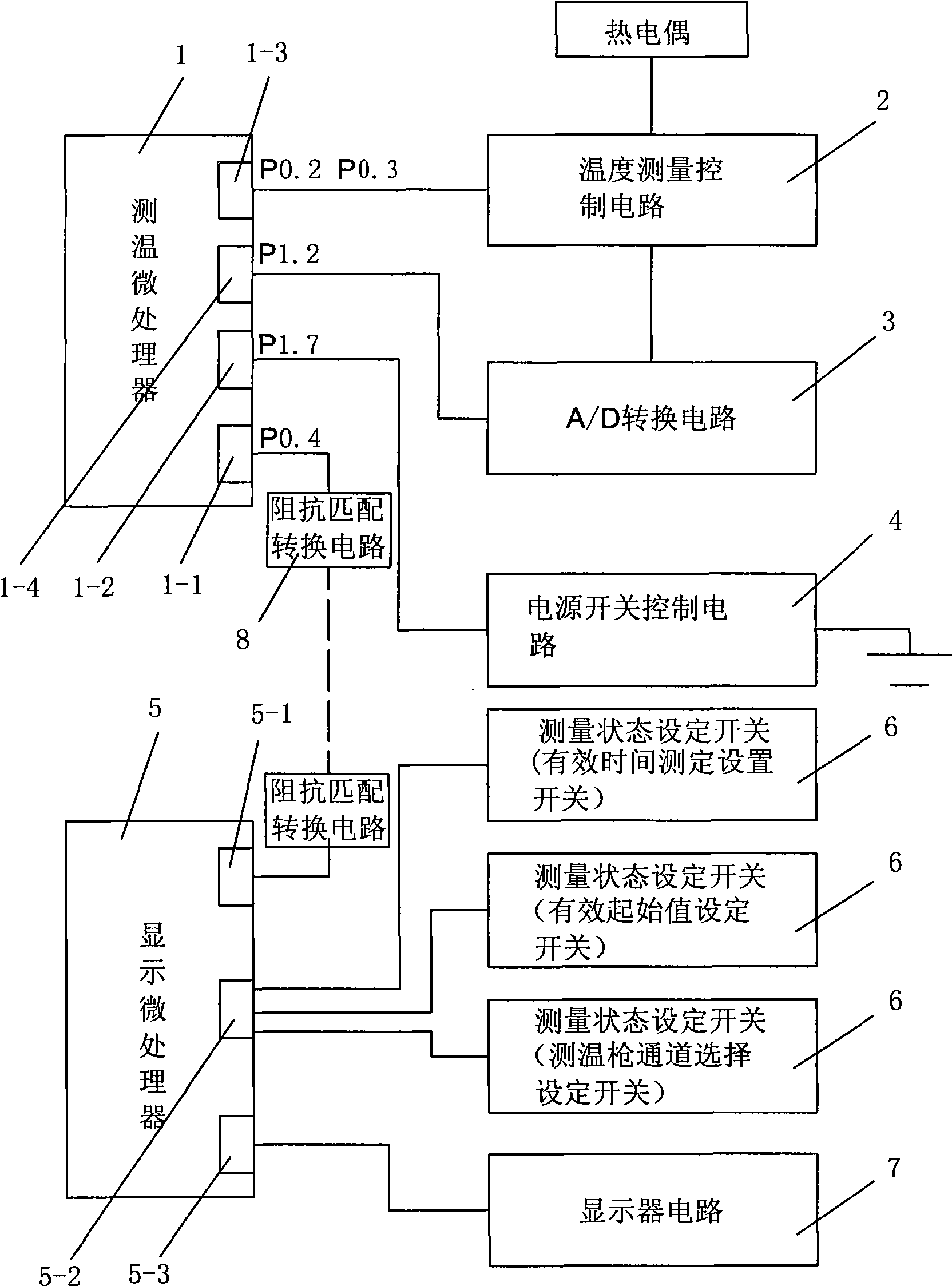

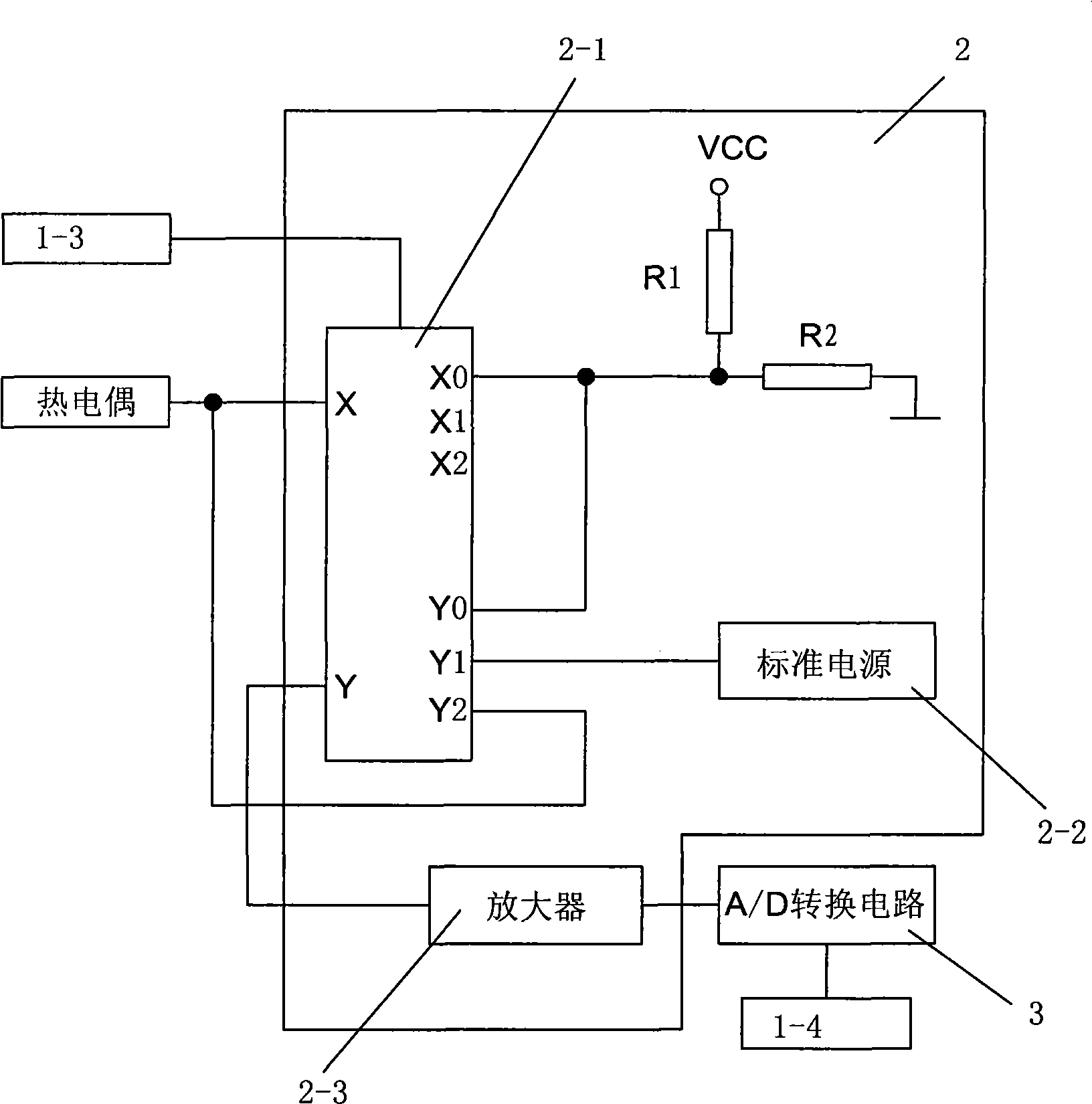

[0028] An embodiment of a wireless temperature measuring gun for metal solution, see figure 1 , figure 2 , image 3 , the wireless temperature measuring gun for metal solution includes a temperature measurement control circuit and a temperature display control circuit, and the temperature measurement control circuit includes a temperature measurement microprocessor 1, a temperature measurement control circuit 2, an A / D conversion circuit 3, a power switch Control circuit 4; the temperature display control circuit includes a display microprocessor 5, a temperature measurement state setting switch 6 and a display 7; the temperature measurement microprocessor includes a wireless data modulation and demodulation receiving and sending port 1-1, a power supply Self-locking control port 1-2, temperature measurement control switch control port 1-3 and A / D conversion digital receiving port 1-4; display microprocessor includes wireless data modulation and demodulation receiving and se...

Embodiment 2

[0037] A working method embodiment of a wireless temperature measuring gun for metal solution, see Figure 4 , Figure 5 , Figure 6 , the method is realized by the metal solution described in embodiment 1 with a wireless temperature measuring gun, and the working method includes traditional temperature full-scale correction and zero point correction steps, and also includes a power switch control step, a temperature measurement control step and a thermocouple measurement Accuracy calibration steps:

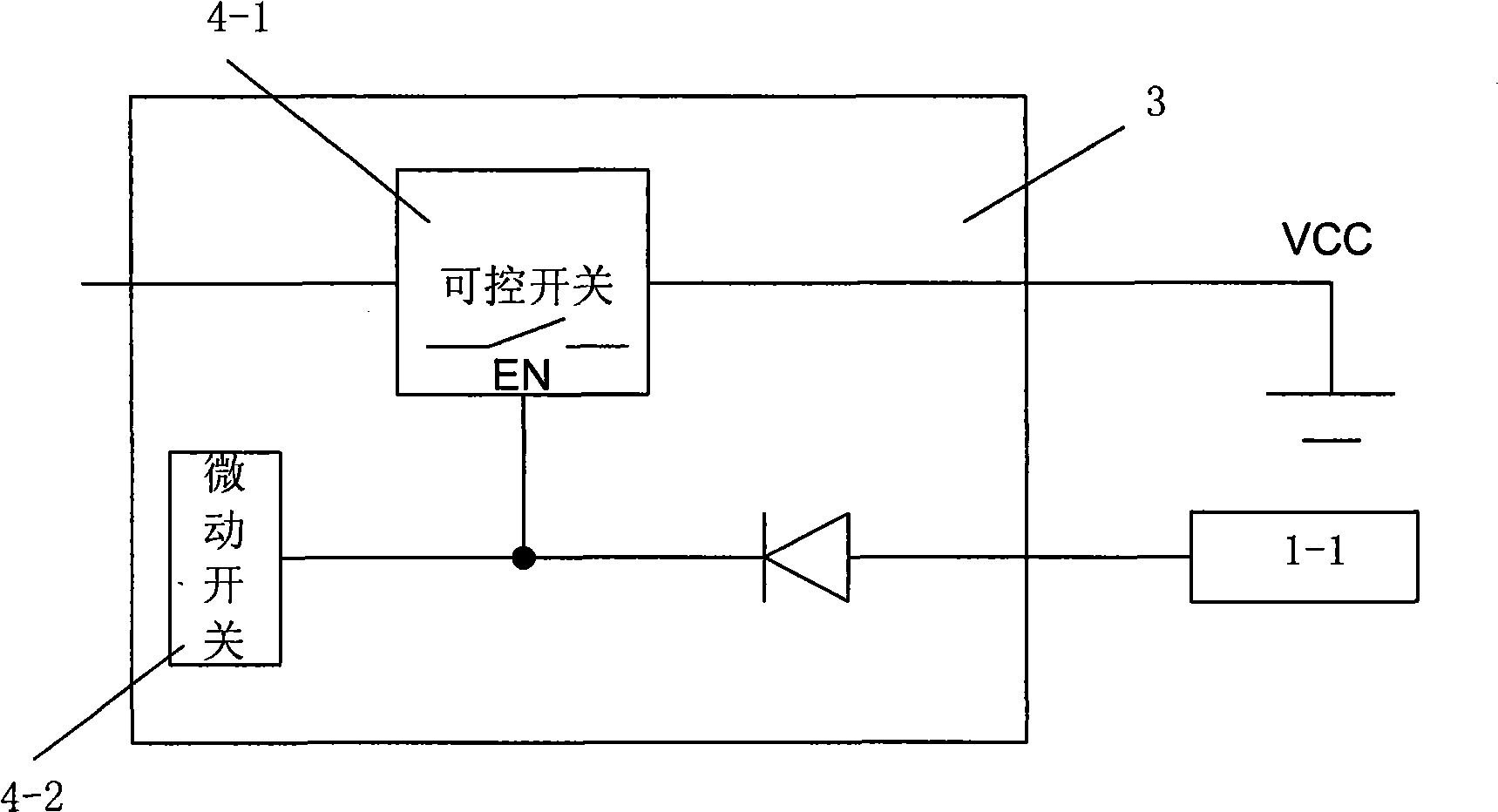

[0038] The power switch control step is: setting a controllable switch and a micro switch in the power switch control circuit, the micro switch is connected to the control end of the control switch, when the micro switch sends a control terminal to open the control switch After power on signal as Figure 4 shown;

[0039] 401. The temperature-measuring microprocessor sends out a continuous connection signal of the locking controllable switch through the self-locking control p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electric potential / voltage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com