A manufacturing method of colour light filter

A technology of color filter and production method, applied in optics, nonlinear optics, instruments, etc., can solve problems such as high cost and high pollution, and achieve the effect of reducing cost and reducing the number of times of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] Hereinafter, specific preferred embodiments of the present invention will be described with reference to the drawings. The drawings illustrate a specific embodiment that can be implemented in the present invention, but other specific embodiments are not excluded, and the steps can be done. The adjustment still does not depart from the scope of the present invention.

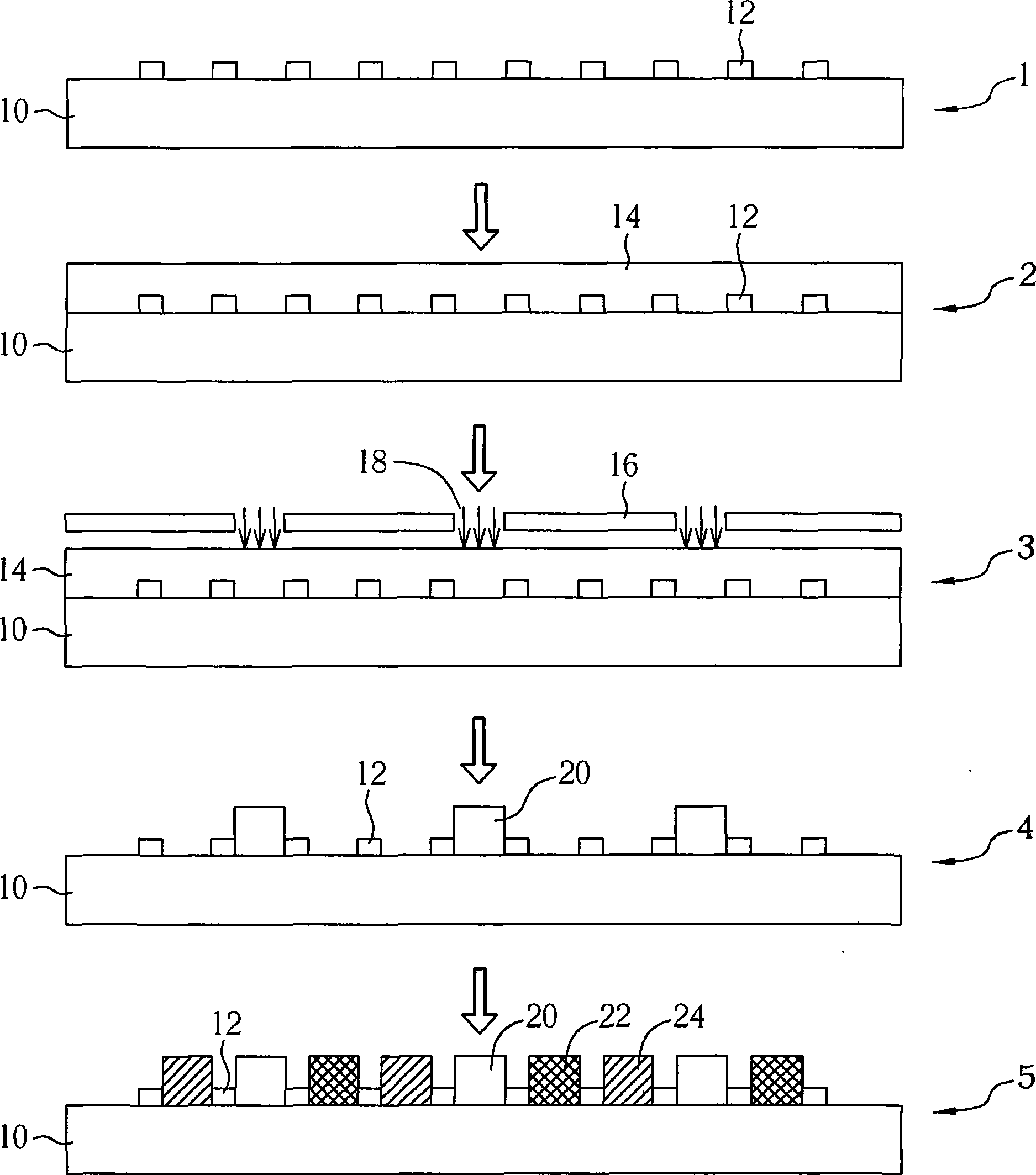

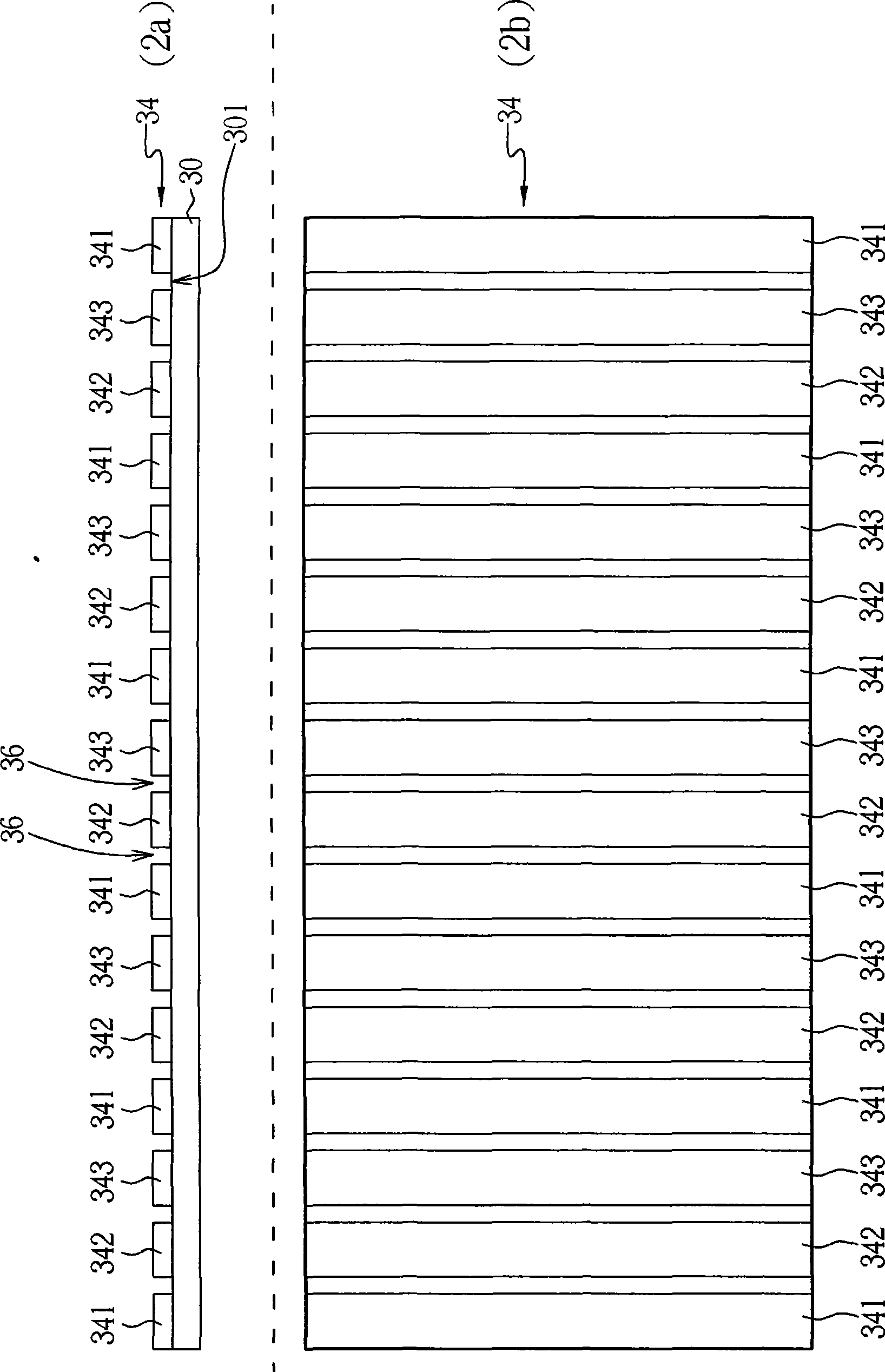

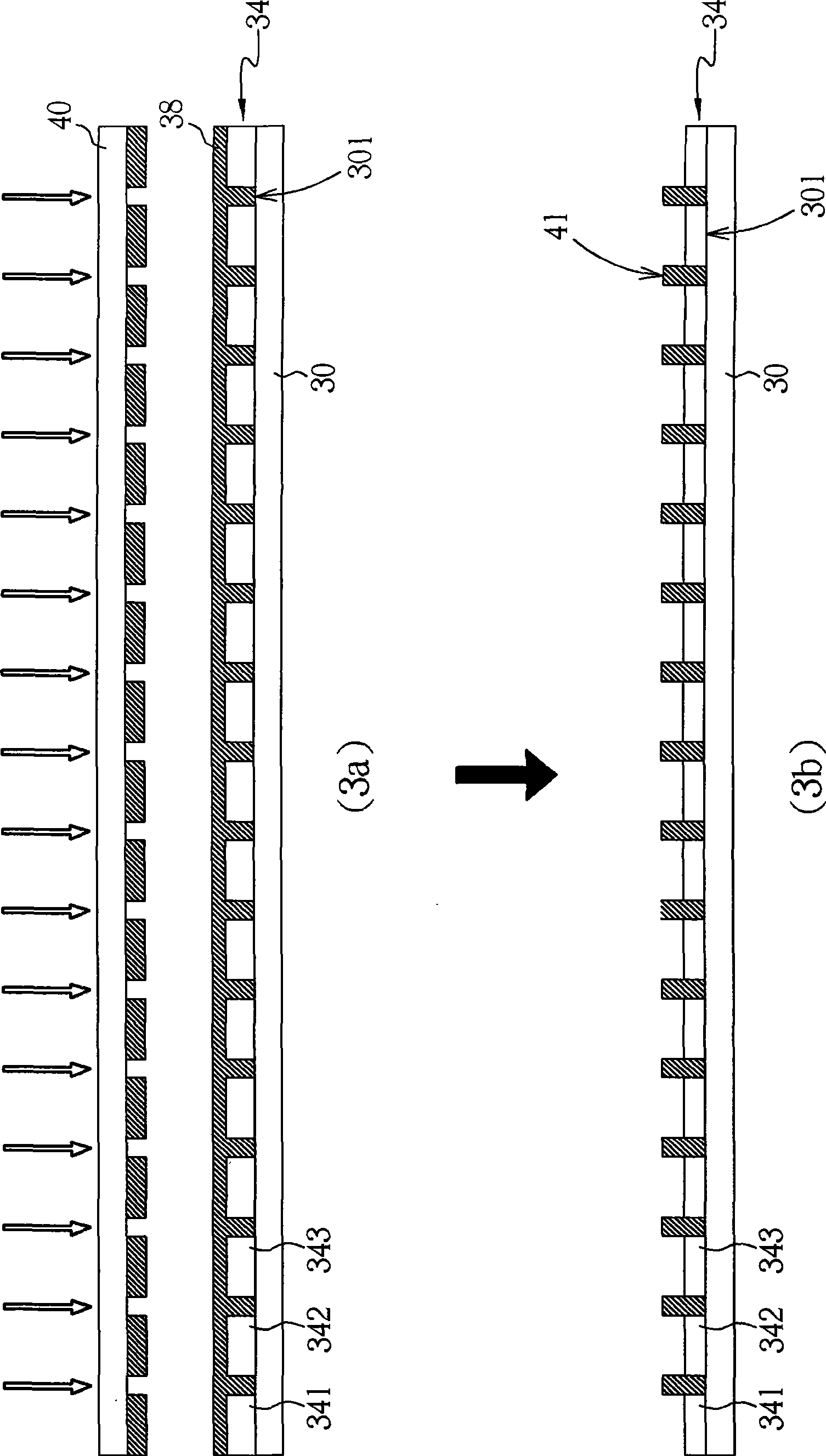

[0054] Figure 2 to Figure 6 It is a schematic flow diagram of a color filter manufacturing method according to a first preferred embodiment of the present invention. Please refer to figure 2 a and figure 2 b, where figure 2 a is the side view, figure 2 b is a top view, first of all figure 2 As shown in a, a substrate 30 is provided, such as a plastic substrate, a glass substrate, or a quartz substrate, and a transparent conductive layer (not shown) is formed on an upper surface 301 of the substrate 30. The transparent conductive layer may include indium oxide Tin (indiumtin oxide, ITO) or indium zinc ox...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap