Cardan type universal joint automatic drilling device

A technology of drilling device and universal joint, which is applied in positioning device, feeding device, boring/drilling, etc., can solve the problems that workers are easy to miss processing, affect work efficiency, and low production efficiency, so as to achieve reasonable speed control, The effect of improving production efficiency and reducing production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

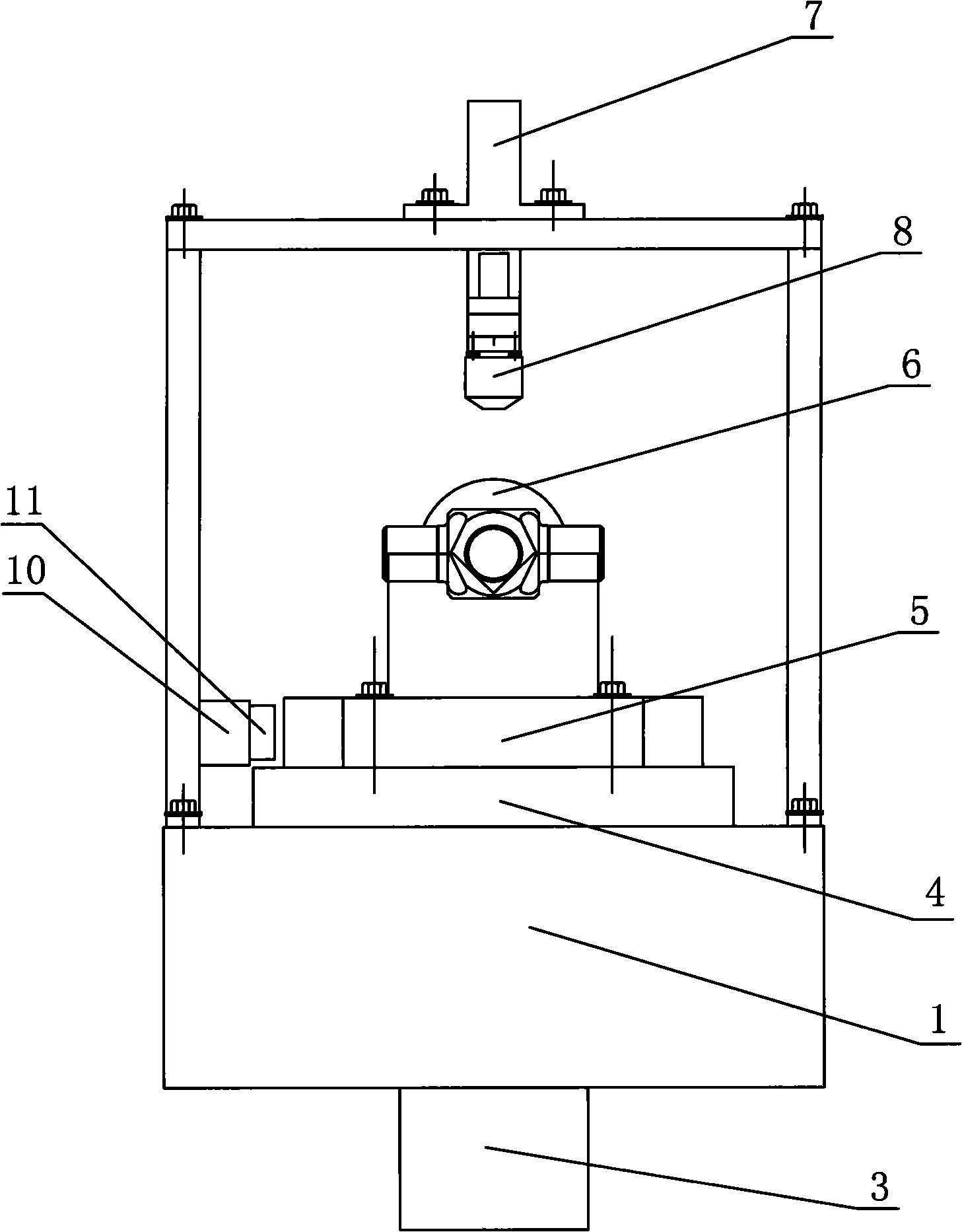

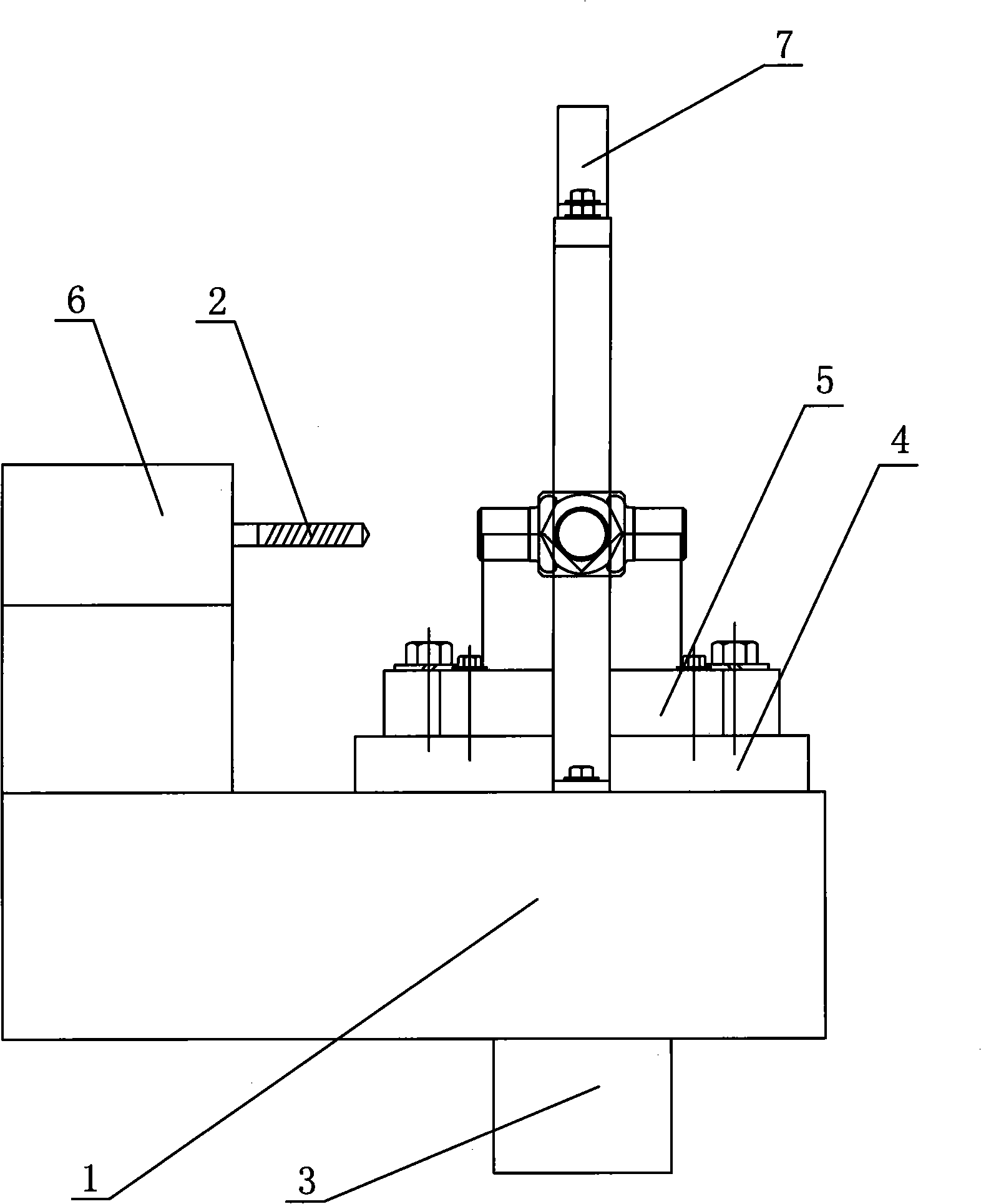

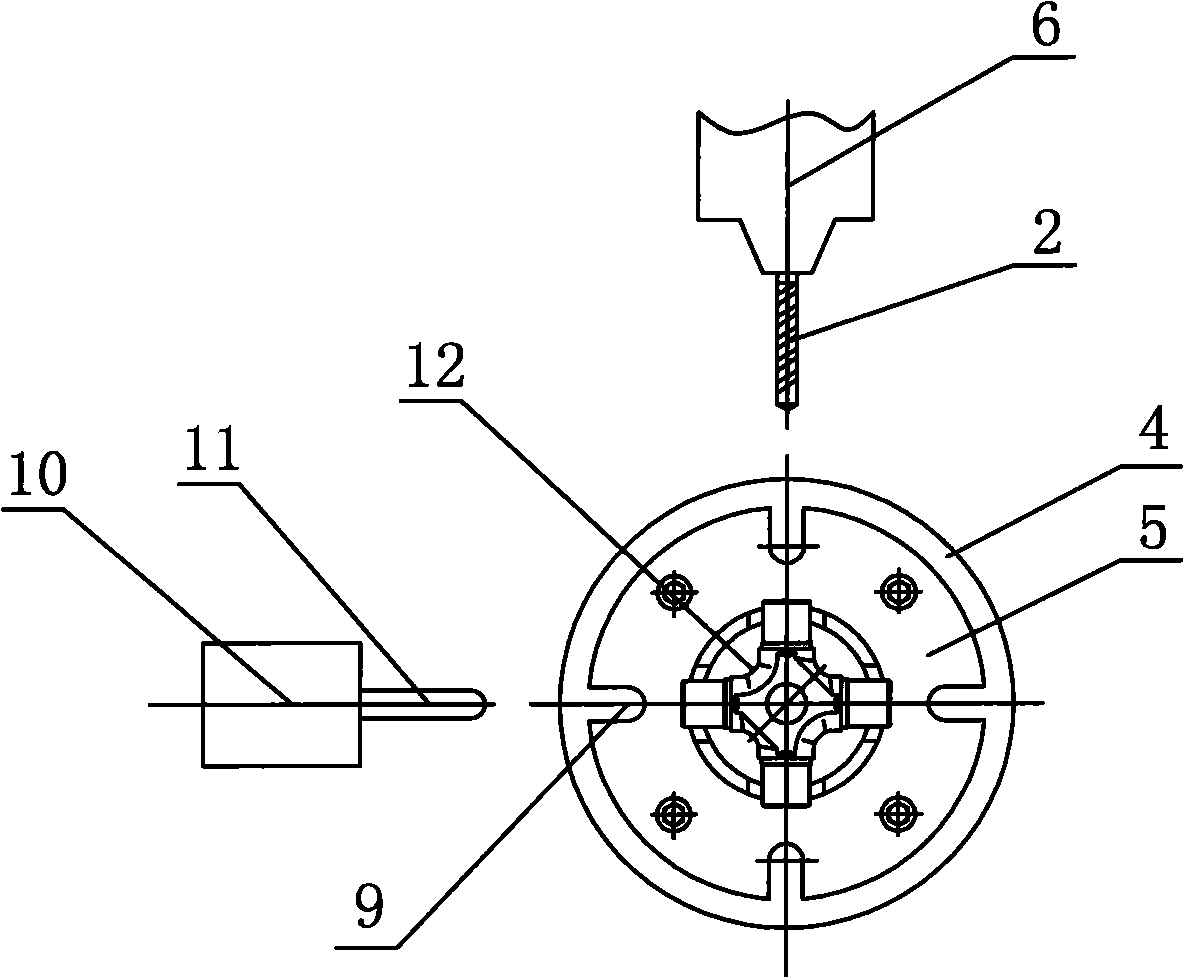

[0016] like Figure 1 to Figure 3 , a cross-axis type universal joint automatic drilling device, a cross-axis type universal joint automatic drilling device, comprising a workbench 1, a drill bit 2 arranged on the workbench 1, the workbench 1 is provided with Through the automatic indexing table 4 controlled by the stepping motor 3 of the indexing table, the automatic indexing table 4 is provided with a clamp 5, and the shaft diameter of the universal joint after the clamp 5 is mounted on the cross shaft type universal joint is the same as that of the drill bit. 2 corresponds, the drill bit 2 is controlled by a drill bit stepping motor 6 . A hydraulic cylinder 7 is arranged above the fixture 5 on the workbench 1 , and a hydraulic pressure head 8 corresponding to the center of the fixture 5 is arranged on the hydraulic cylinder 7 . The fixture 5 is provided with a slot 9 , and the workbench 1 is provided with a cylinder 10 , and the cylinder 10 is provided with a latch 11 corr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com