Processing system for opening and welding plastic oil tank

A processing system and oil tank technology, applied in metal processing, household components, household appliances, etc., can solve the problems of low efficiency, positioning error, and occupying a large production site, so as to reduce the occupied space of production, increase the rate of finished products, and improve the processing accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] Specific embodiments of the present invention are described with reference to the above drawings.

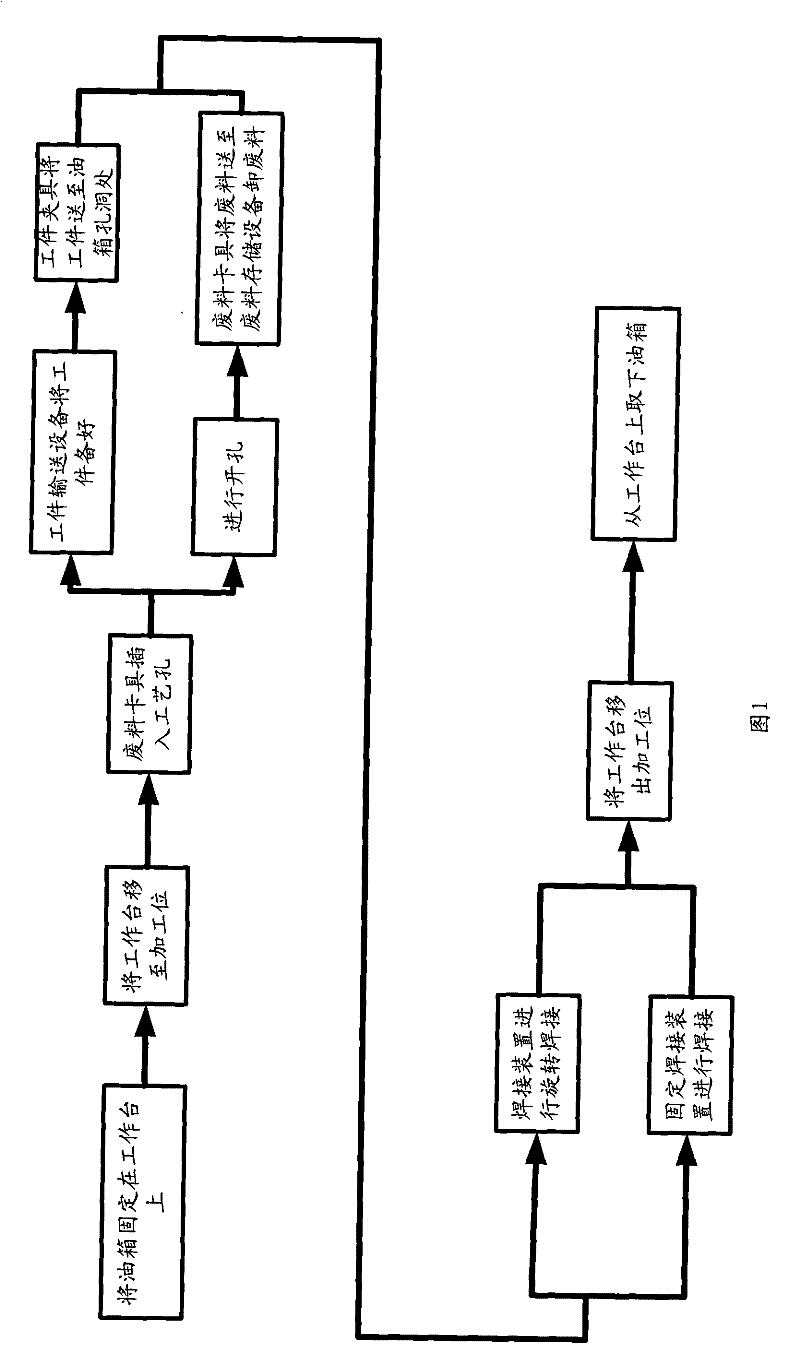

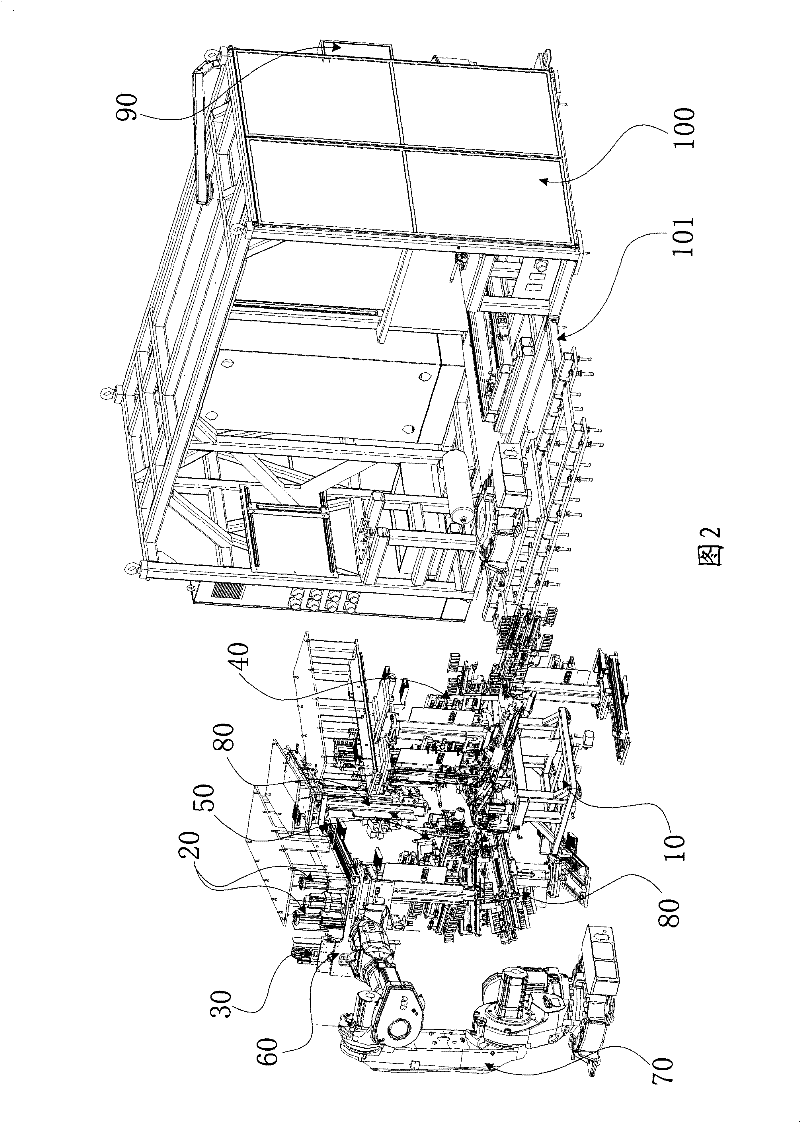

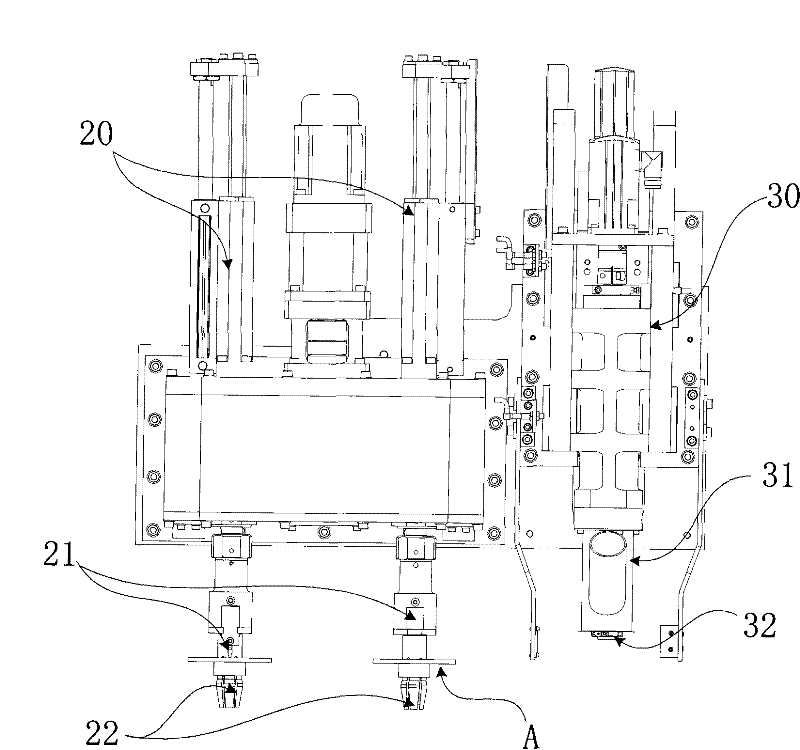

[0013] Depend on figure 1 and figure 2 As can be seen in the above, a plastic fuel tank drilling and welding processing system includes a workbench 10 for carrying and positioning a plastic fuel tank, a drilling unit 20, a welding unit 30, a workpiece conveying unit 40, a waste storage unit 50 and a control unit for controlling the above-mentioned equipment The device 90 ; the processing system also includes a frame 100 , the workbench 10 , the drilling unit 20 , the welding unit 30 , the workpiece conveying unit 40 and the waste storage unit 50 are all arranged in the frame 100 and connected to the frame 100 . The frame 100 is an overall fixed work frame, and all the processing equipment of the processing system are connected in the frame, which has a unified positioning reference. In addition, the plastic oil tank to be processed is only fixed on the only work table, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com