Bicycle frame and manufacture method thereof

A manufacturing method and bicycle technology, applied to bicycle frames, bicycle accessories, manufacturing tools, etc., can solve problems affecting product quality, safety hazards, and lack of fullness, and achieve the effects of solving processing bottlenecks, high safety, and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings.

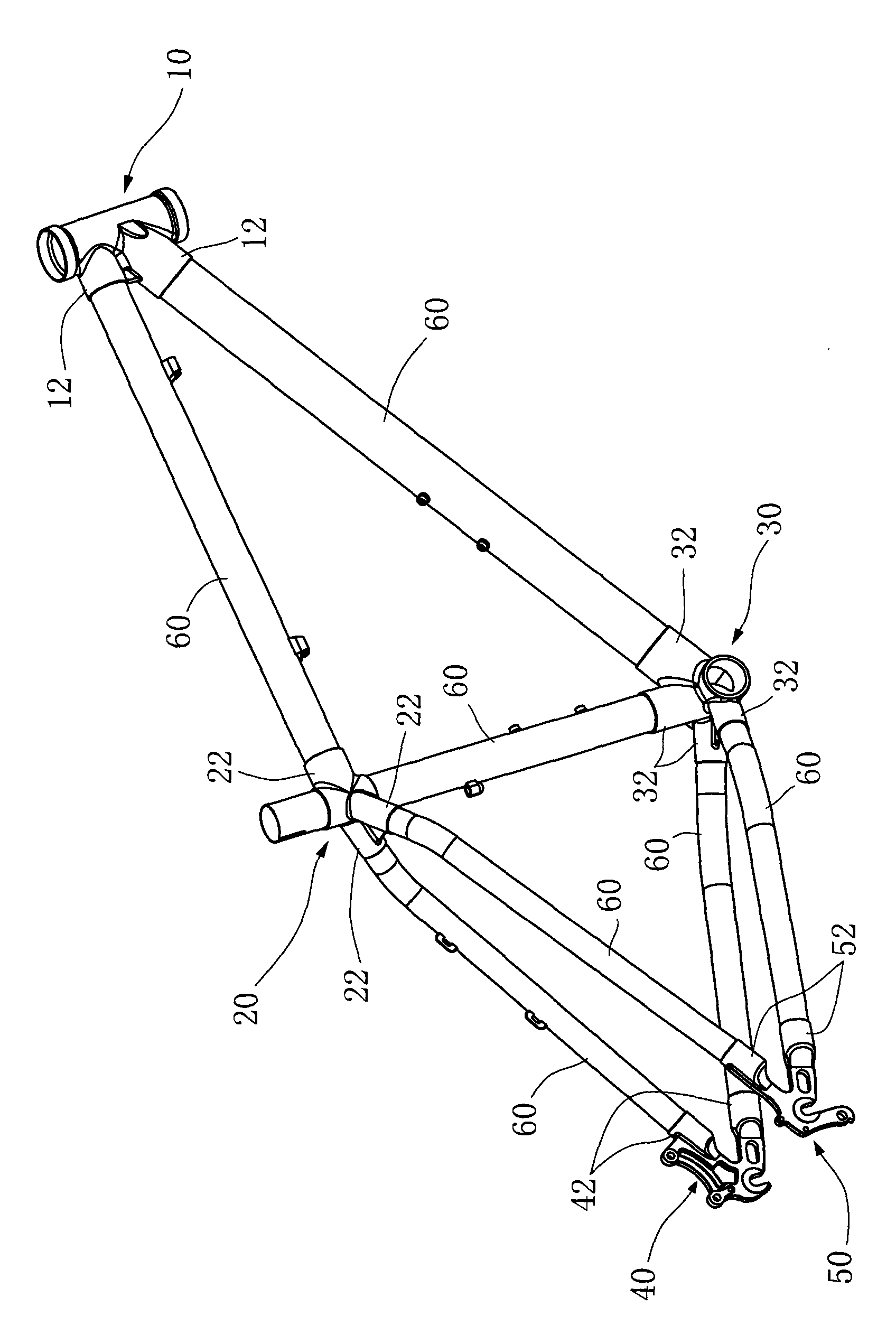

[0022] See attached figure 1 , The bicycle bracket of the present invention includes: a connecting head and a connecting pipe 60, the connecting head has a connecting sleeve, and one end of the connecting pipe 60 is fixed in the connecting sleeve through a sleeve.

[0023] There are multiple connectors, including a handle connector 10, a seat cushion connector 20, a pedal connector 30, a left wheel connector 40, and a right wheel connector 50. The connectors are connected through a connecting pipe 60 to form a bicycle. The main body of the bracket, wherein the shape of the handle connector 10, the seat cushion connector 20, the pedal connector 30, the left wheel connector 40, the right wheel connector 50 and the connecting pipe 60 is basically consistent with the shape of the existing parts, Therefore, too many explanations are not given in the following description t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com