Entrained flow reactor temperature control system and control method thereof

A temperature control system and reactor technology, applied in the field of coal gasification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

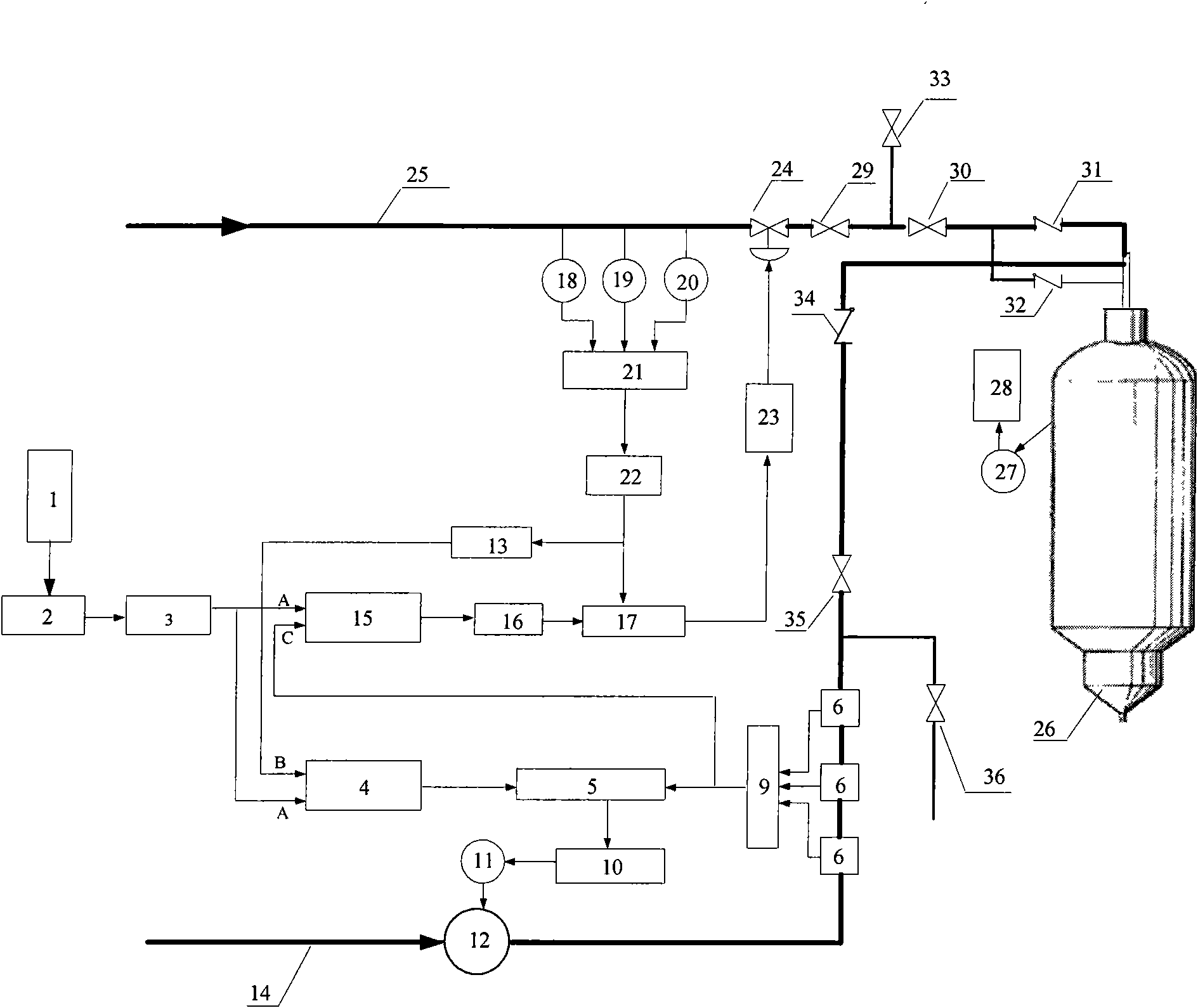

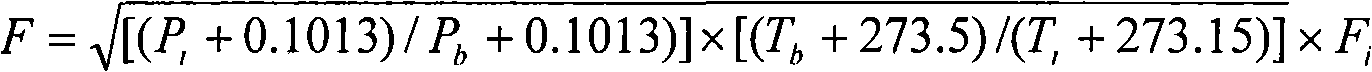

[0093] The operating conditions of the coal-water slurry entrained bed reactor with a single reactor daily processing capacity of 1065 tons of coal using Henan Yima coal as raw material are as follows: the gasification agent uses oxygen with a purity of 99.6% by volume, and the flow rate of oxygen into the furnace is 25104.75Nm 3 / h, the concentration of the coal slurry is 65% by weight based on the total weight of the coal slurry, the flow rate of the slurry into the furnace is 68613kg / h, the operating pressure of the entrained bed reactor is 6.5MPa, the furnace operating temperature is 1350°C, the oxygen / coal The volume ratio of the slurry was 447. The temperature control system of the entrained bed reactor adopts figure 1 control system shown. exist figure 1 In the process, the slurry is pressurized to 7.8MPa by a high-pressure slurry pump and then sent to the burner, and then sprayed into the reactor together with 8.2MPa oxygen through the burner. After the slurry ent...

Embodiment 2

[0106] In a production plant with an annual output of 300,000 tons of synthetic ammonia in China, the gasification unit uses mixed coal from Sunjiahao and Baoping Bay (Sunjiahao coal: Baoping Bay coal = 3:7 by weight) as raw material. The daily processing capacity of the reactor is 845.16 tons of coal. The gasification agent uses oxygen with a purity of 99.6% by volume. 6.5MPa, the operating temperature of the furnace is 1340°C, and the standard volume ratio of oxygen / slurry is 472.

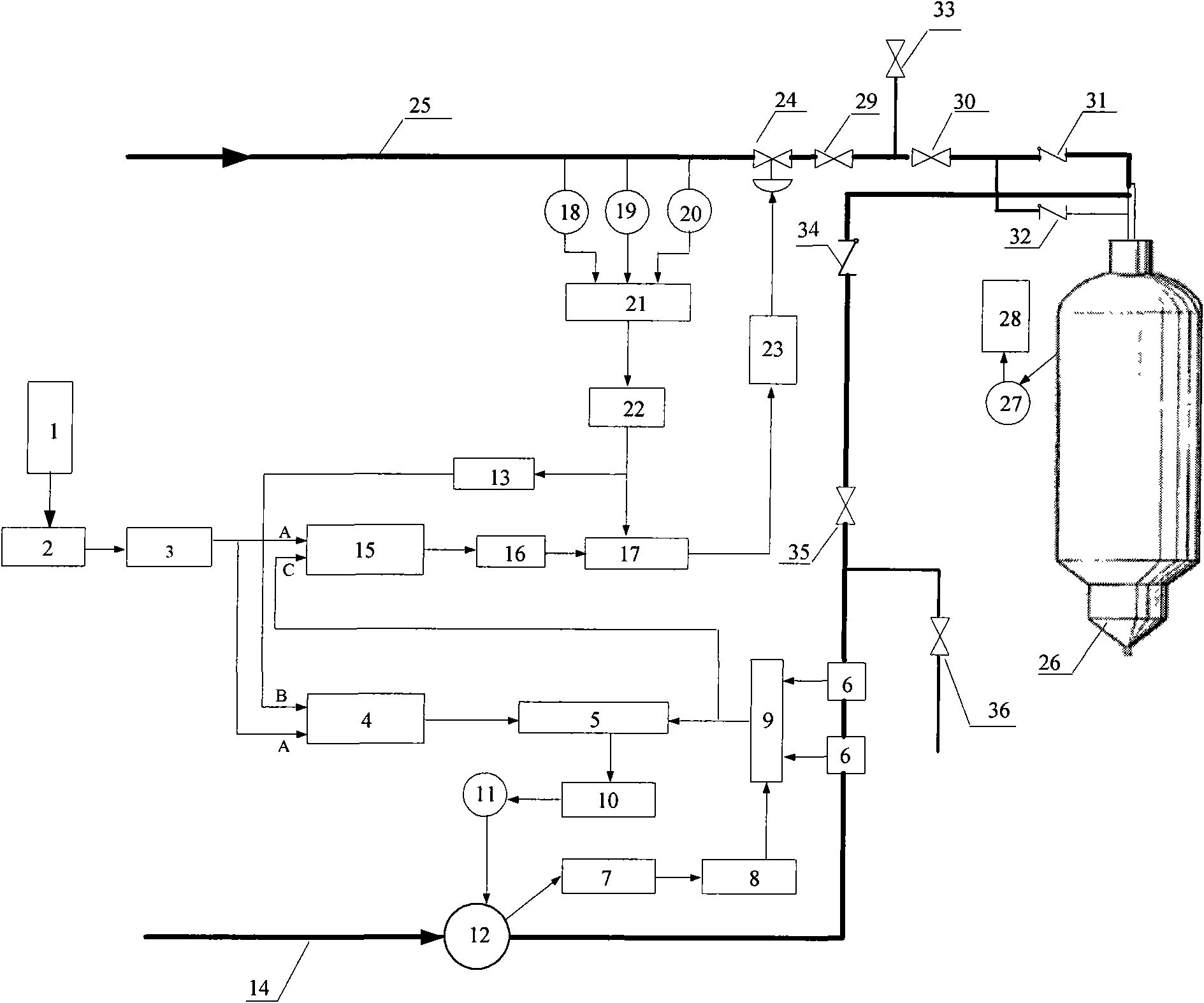

[0107] In this embodiment, the temperature control method of the entrained bed reactor adopts the control method of the present invention, and the temperature control system of the entrained bed reactor adopts figure 2 control system shown. In the control system, two electromagnetic flowmeters are used to measure the instantaneous flow of the slurry, and the speed of the high-pressure slurry pump is converted into the instantaneous flow of the slurry. The three slurry flow signals are input to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com