Emergency road slab made of composite material and mounting method thereof

A composite material and pavement panel technology, applied in the directions of roads, roads, special pavements, etc., can solve the problems of damage to pavement panels, inability to lay double layers, and inability to achieve rapid disassembly and assembly, and achieve the effect of convenient disassembly and installation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] The accompanying drawings show the embodiments of the present invention, and the embodiments of the present invention will be further described below in conjunction with the accompanying drawings, but not as a limitation of the present invention.

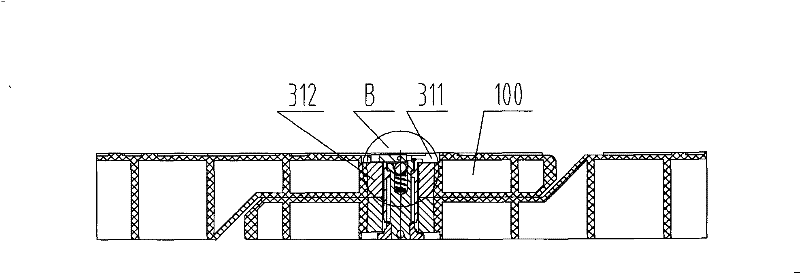

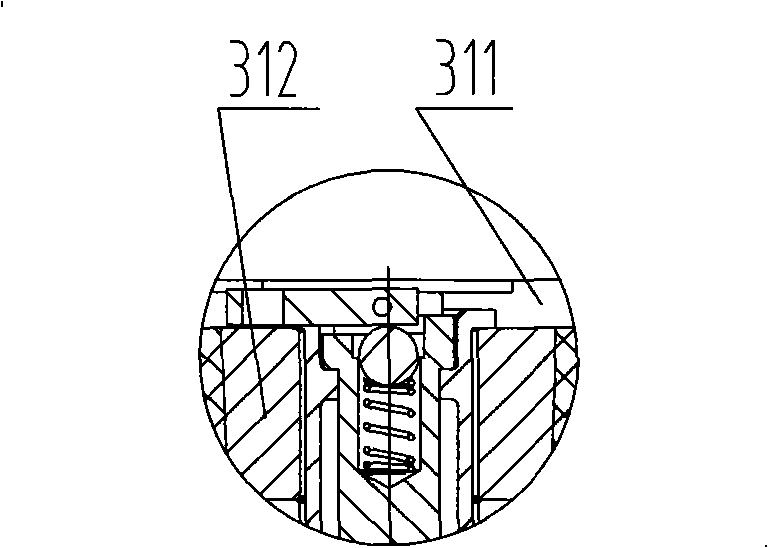

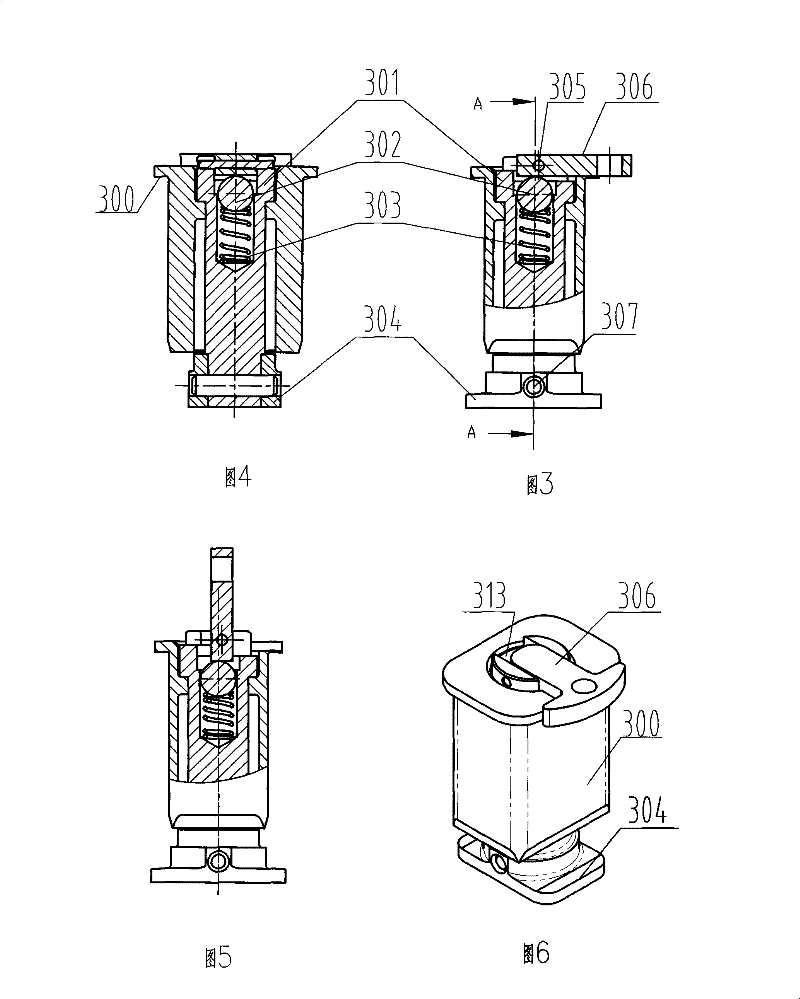

[0056] The overall structure of the present invention is as shown in the figure, which includes a road slab 100 made of composite material, L-shaped flanges 106 that are arranged on the adjacent two peripheries of the road slab 100 and are concave, and set on the L-shaped flange 106 and the road slab 100. The installation hole 101 on the upper surface, the corresponding installation hole 101 on the adjacent road panel 100 is pierced and connected with a connecting member, and a sub-board 105 is fixed under the road panel 100 on the same side of the L-shaped flange 106, and the sub-board 105 The bottom is coplanar with the lower part of the L-shaped flange 106, and the connecting member is assembled with the mounting hole 311 t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com