Gas and oil separating plant for internal combustion engine

A separation device and internal combustion engine technology, applied in mechanical equipment, engine components, machines/engines, etc., can solve the problems of large volume, complex structure of oil-gas separation device, insufficient oil-gas separation, etc., achieve complete oil-gas separation, and facilitate the layout of the whole machine , the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further elaborated below according to the drawings and specific embodiments.

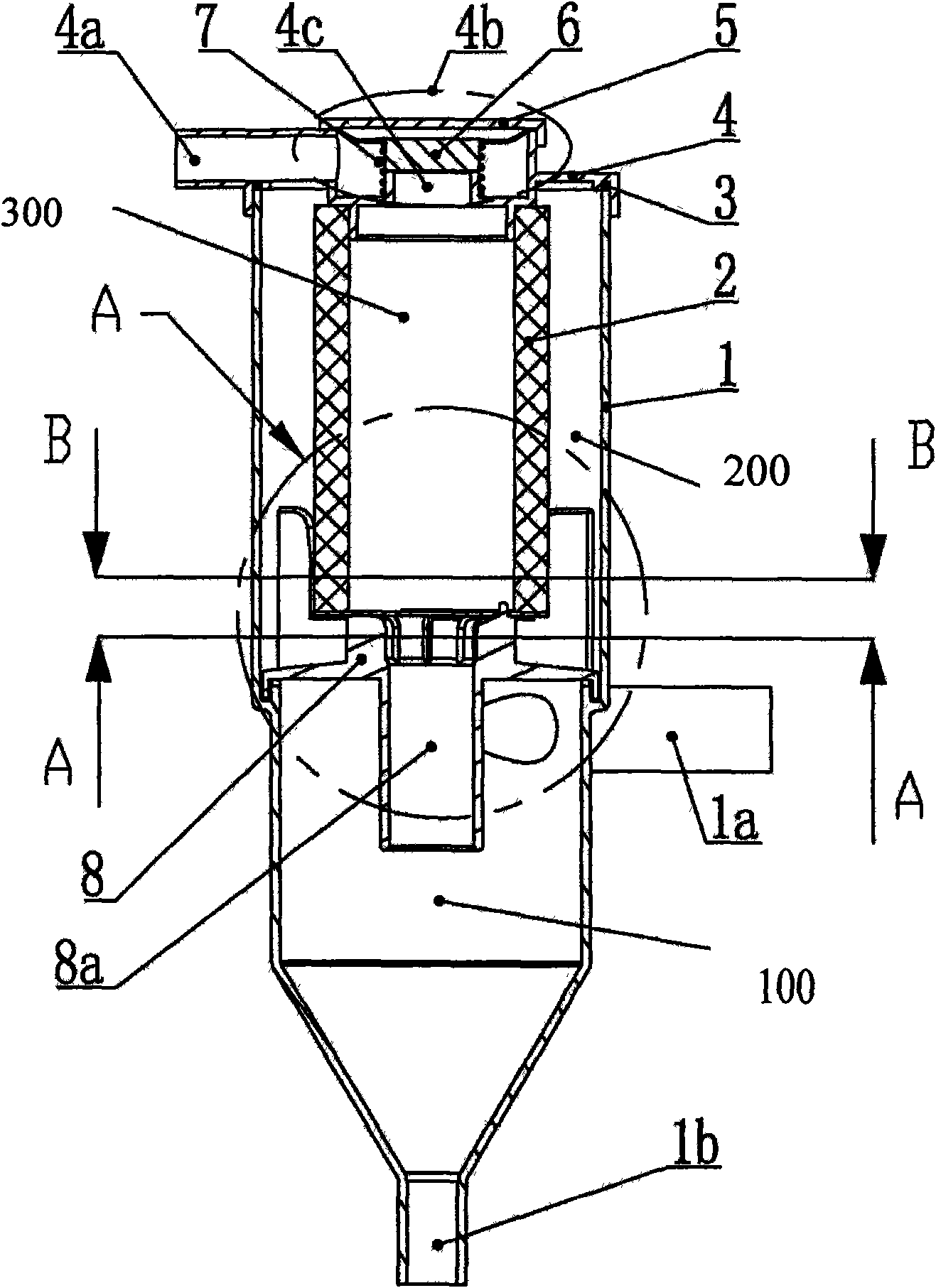

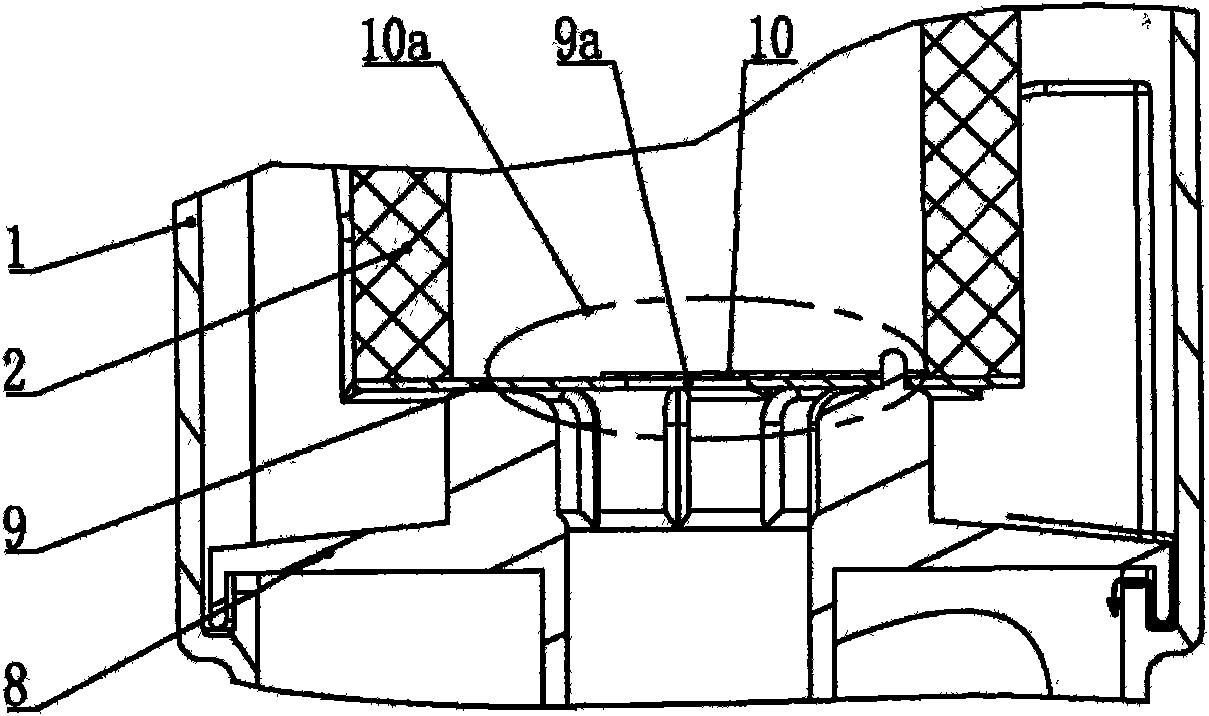

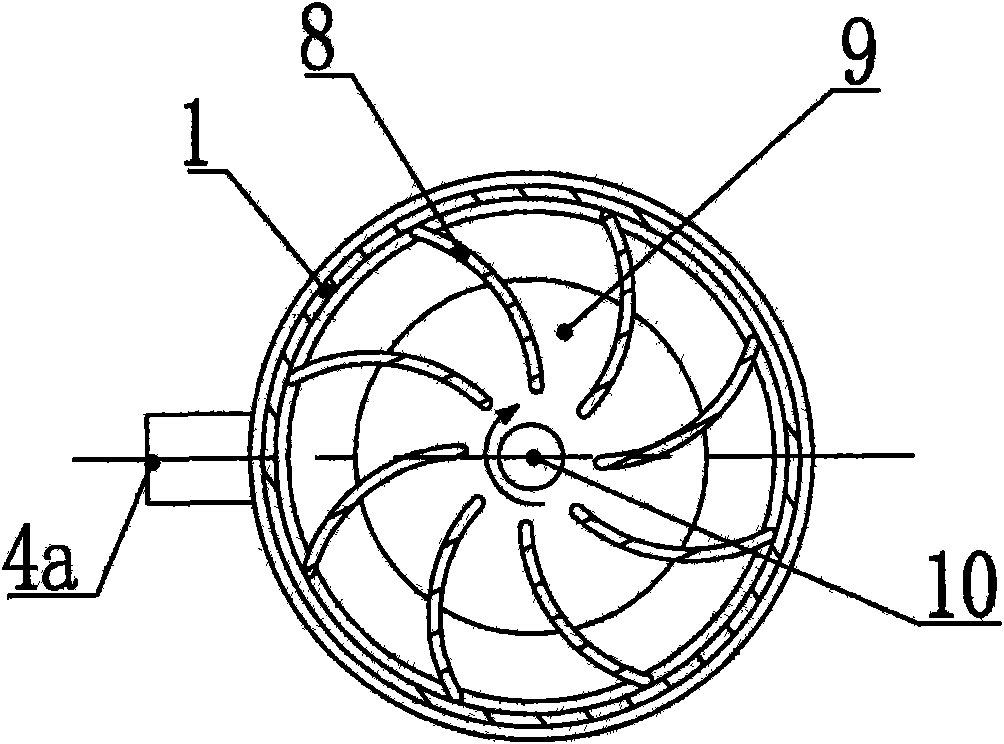

[0016] like figure 1 As shown, the present invention provides a kind of oil-gas separation device of internal combustion engine, and it comprises three parts: the first separation chamber 100 (being cyclone oil-gas separation chamber), the second separation chamber 200 (being baffle plate oil-gas separation chamber) and the 3rd The separation chamber 300 (i.e. the filter screen oil-gas separation chamber), the air inlet 1a of the first separation chamber 100 is directly connected with the crankcase, and the air outlet pipe 8a (i.e. the ascending air pipe) of the first separation chamber 100 passes through the baffle plate 8 to the second The second separation chamber 200, and finally the mixed gas filter is passed to the third separation chamber 300, and enters the intake manifold of the internal combustion engine through the pressure control valve 4b.

[0017] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com