Thermoacoustic engine for outputting rotary power

A thermoacoustic engine and rotary power technology, applied in the direction of mechanisms, machines/engines, and mechanical equipment that generate mechanical power. It can solve the problems of low wear, low efficiency, and short life, and achieve long service life and good controllability. , the effect of high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

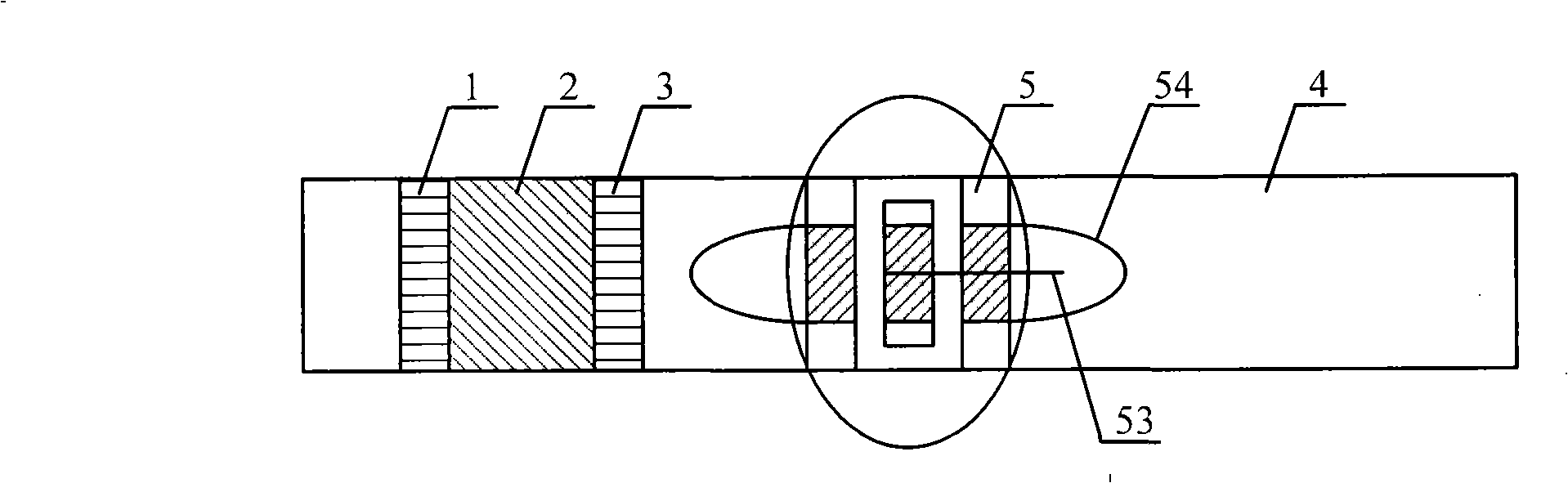

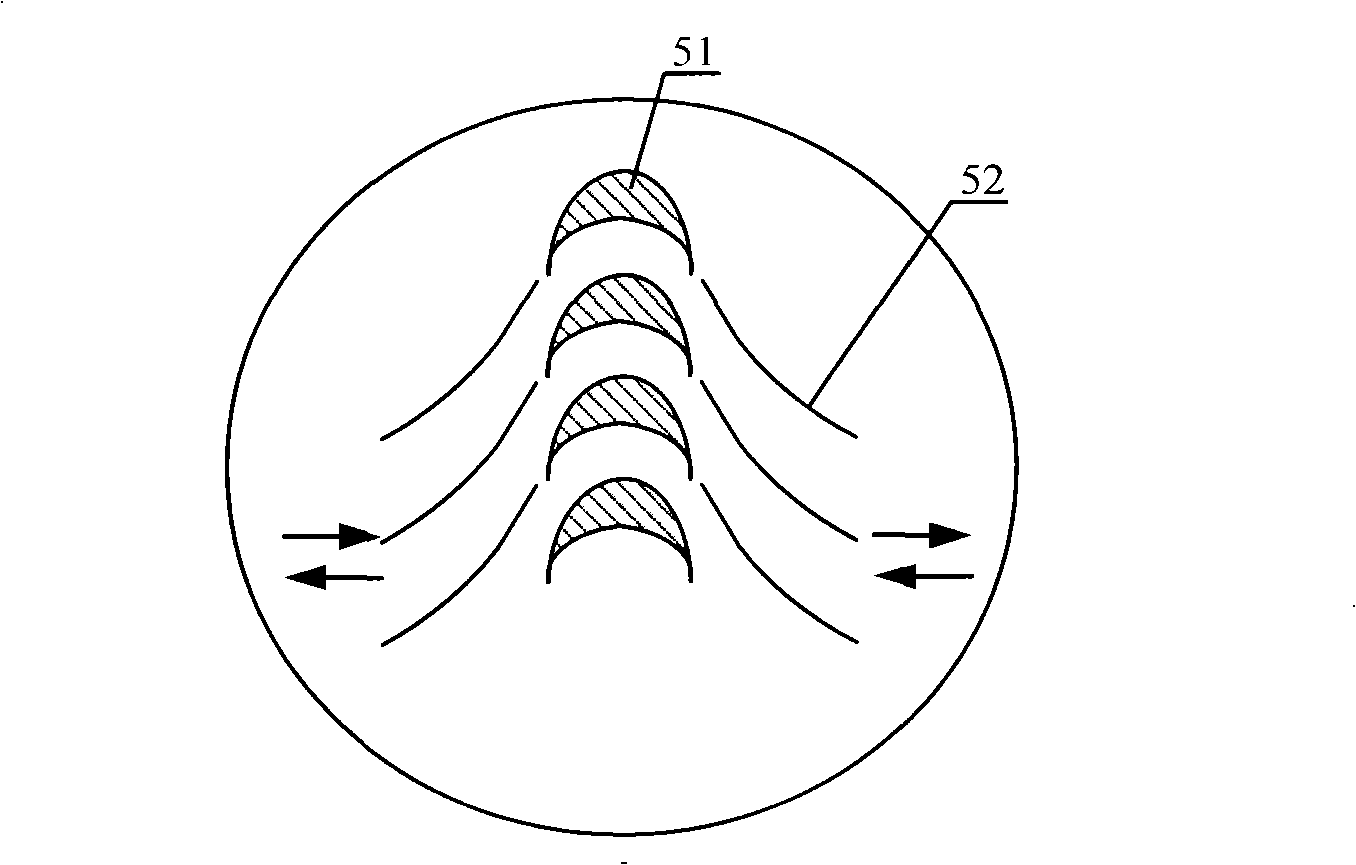

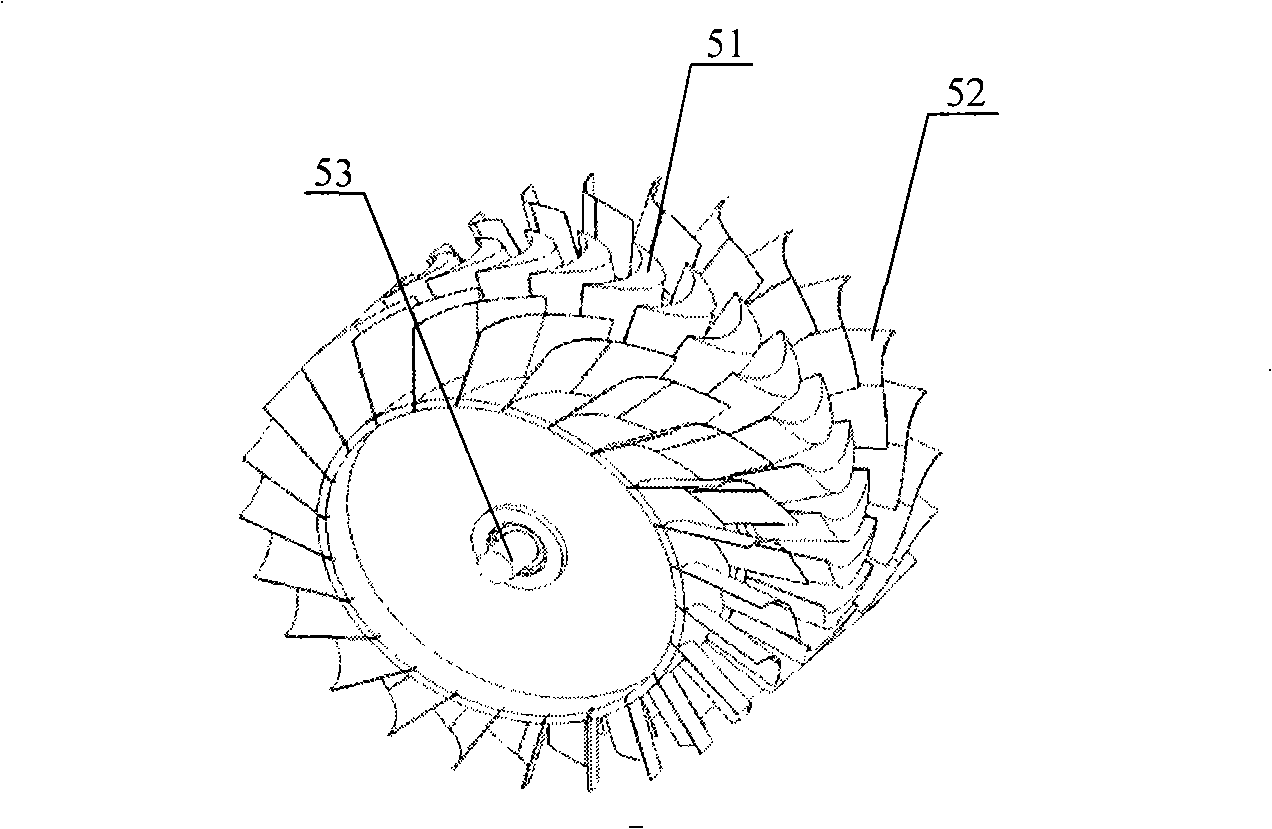

[0027] The thermoacoustic engine that outputs rotational power involved in the present invention, in addition to including the hot-end heat exchanger, plate stack or regenerator, cold-end heat exchanger and resonance tube that conventional thermoacoustic engines have, is also provided with a Self-regulating air turbine device, which is used to convert the alternating flow of oscillating air flow into rotary motion to drive a rotating load. The self-rectifying air turbine device is used to generate rotational power, which is better than the crank connecting rod structure in the prior art, and the output power has excellent characteristics such as small wear, high efficiency, and good controllability, and has wide adaptability . The structure of the thermoacoustic engine that outputs rotational power will be introduced in detail below by installing the self-rectifying air turbine device on various thermoacoustic engines.

[0028] Such as Figure 1A Shown is a schematic structu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com