Device for automatically positioning projection lamp wick in lamp cup and method for positioning same

An automatic positioning, lamp cup technology, applied in lighting devices, projection devices, components of lighting devices, etc., can solve the problem of product consistency and stability difficult to guarantee, identification and judgment difficult to maintain consistency, operator safety hazards, etc. problems, to achieve the effect of shortening the lighting time, eliminating potential damage and ensuring quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

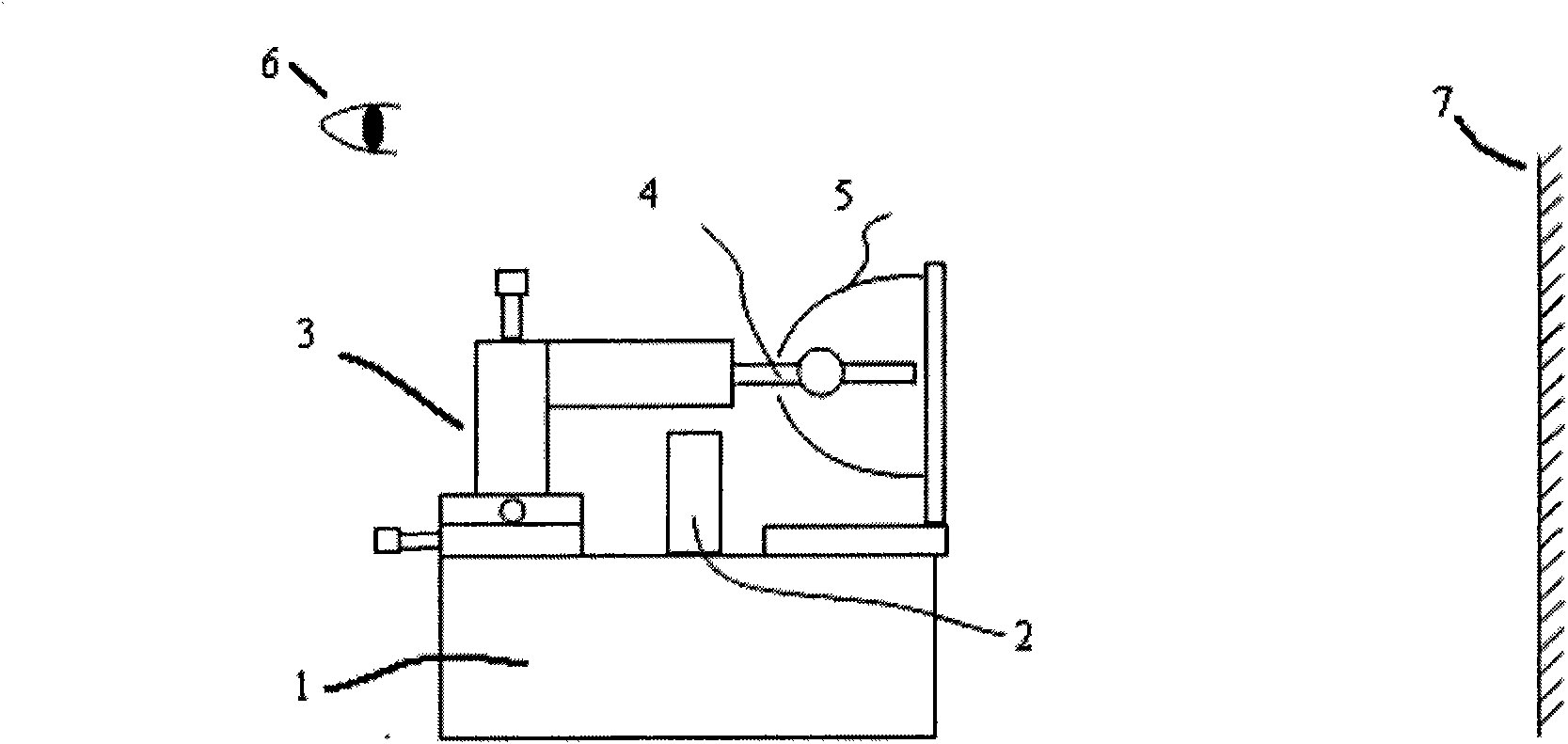

Embodiment 1

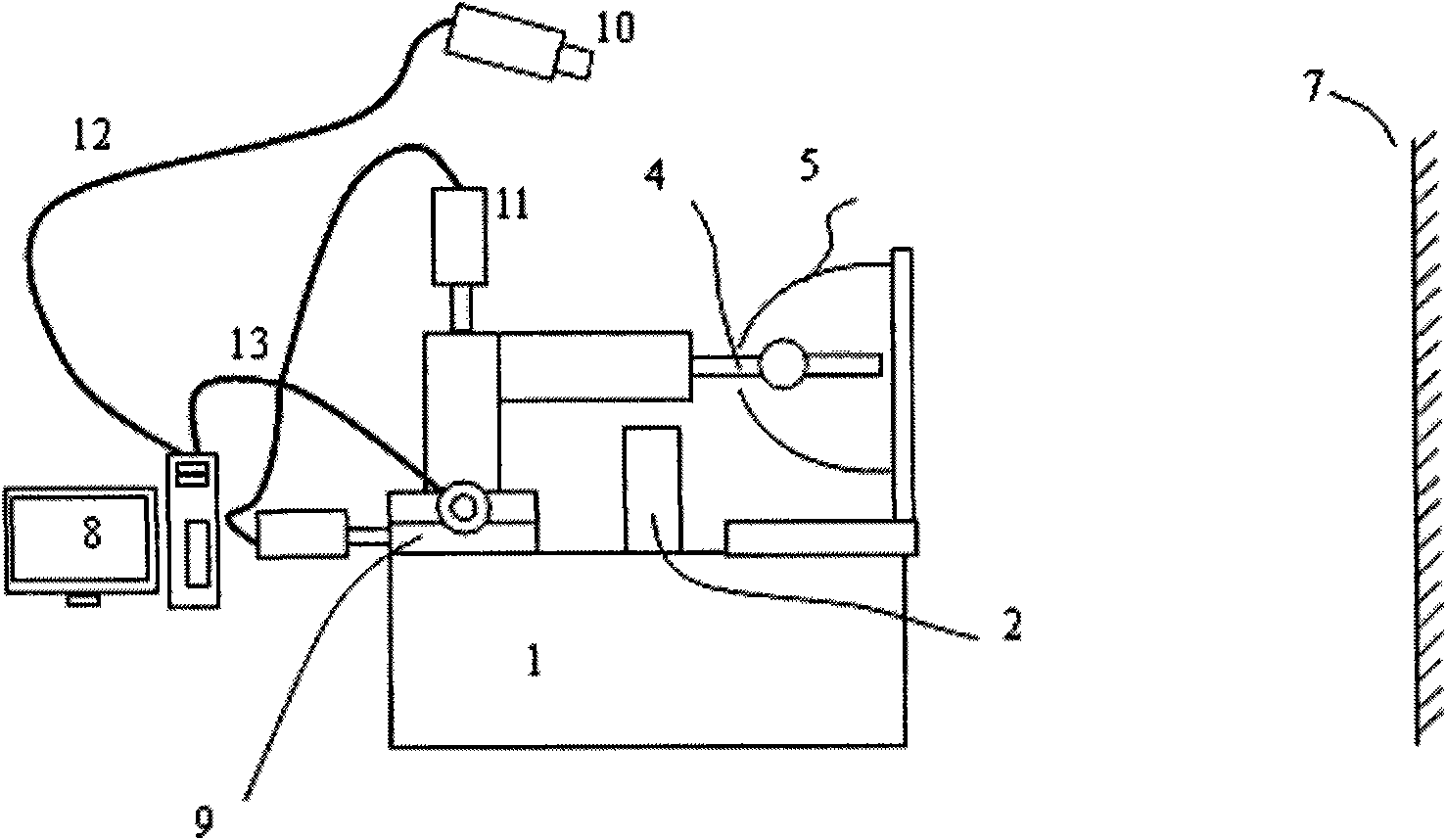

[0056] Vision system: CCD camera, video capture card;

[0057] Image processing system: computer and image processing software;

[0058]Motion control system: a transmission mechanism composed of stepping motor, motion control card, gear or lead screw.

Embodiment 2

[0060] Vision system: USB camera;

[0061] Image processing system: computer and image processing software;

[0062] Motion control system: motion cylinder.

Embodiment 3

[0064] Vision system: camera;

[0065] Image processing system: programmable logic controller (PLC) with image processing function;

[0066] Motion control system: manual translation stage.

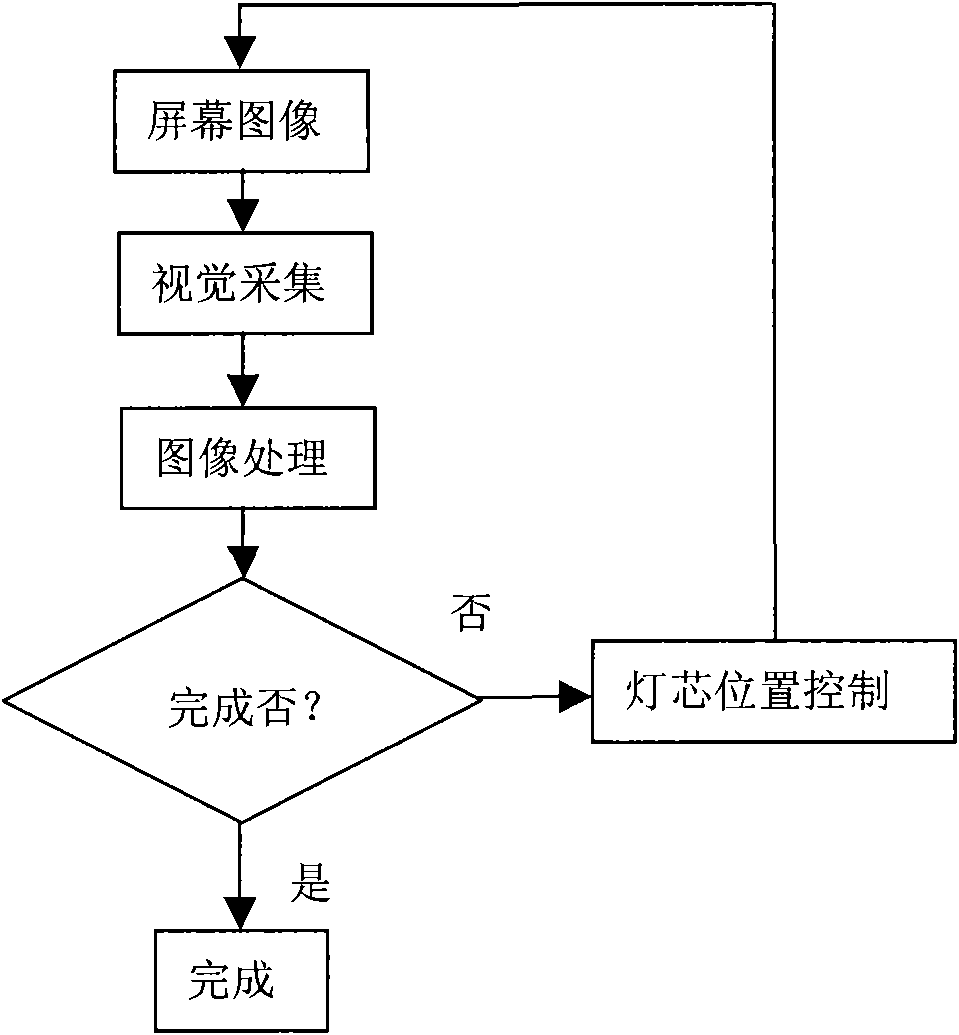

[0067] Correspondingly, the method for automatically positioning the projection wick in the lamp cup in the present invention has the following specific implementation steps:

[0068] The vision system collects and transmits the image projected on the screen 7 by the projection lamp to the image processing system;

[0069] The image processing system first extracts key area parameters such as screen brightness, screen uniformity, contrast, and color temperature after the image data is input;

[0070] Analyze and match the parameters with the empirical data in the database;

[0071] Display performance parameters through the display device;

[0072] Generate motion control parameters and output the parameters;

[0073] Record various data as needed, and display the results of optimization and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com