Multi-purpose ultraviolet ageing system

A multi-purpose, ultraviolet technology, applied in the preparation of test samples, measuring devices, instruments, etc., can solve the problems that the ultraviolet aging system is not targeted, cannot meet the needs of special experiments, and cannot be connected to the instrument, so as to prevent UV light leakage, facilitate heat circulation, protect the environment and human health effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the embodiments shown in the accompanying drawings.

[0025] The system of the present invention mainly includes a main box 1 and a control cabinet 17, the control cabinet 17 and the main box 1 are connected by wires, and the control cabinet 17 provides specific conditions for testing in the main box 1. It may also include a support frame, which may be used in some test situations, such as when the distance between the sample and the light source needs to be adjusted, and the sample can be placed on the support frame.

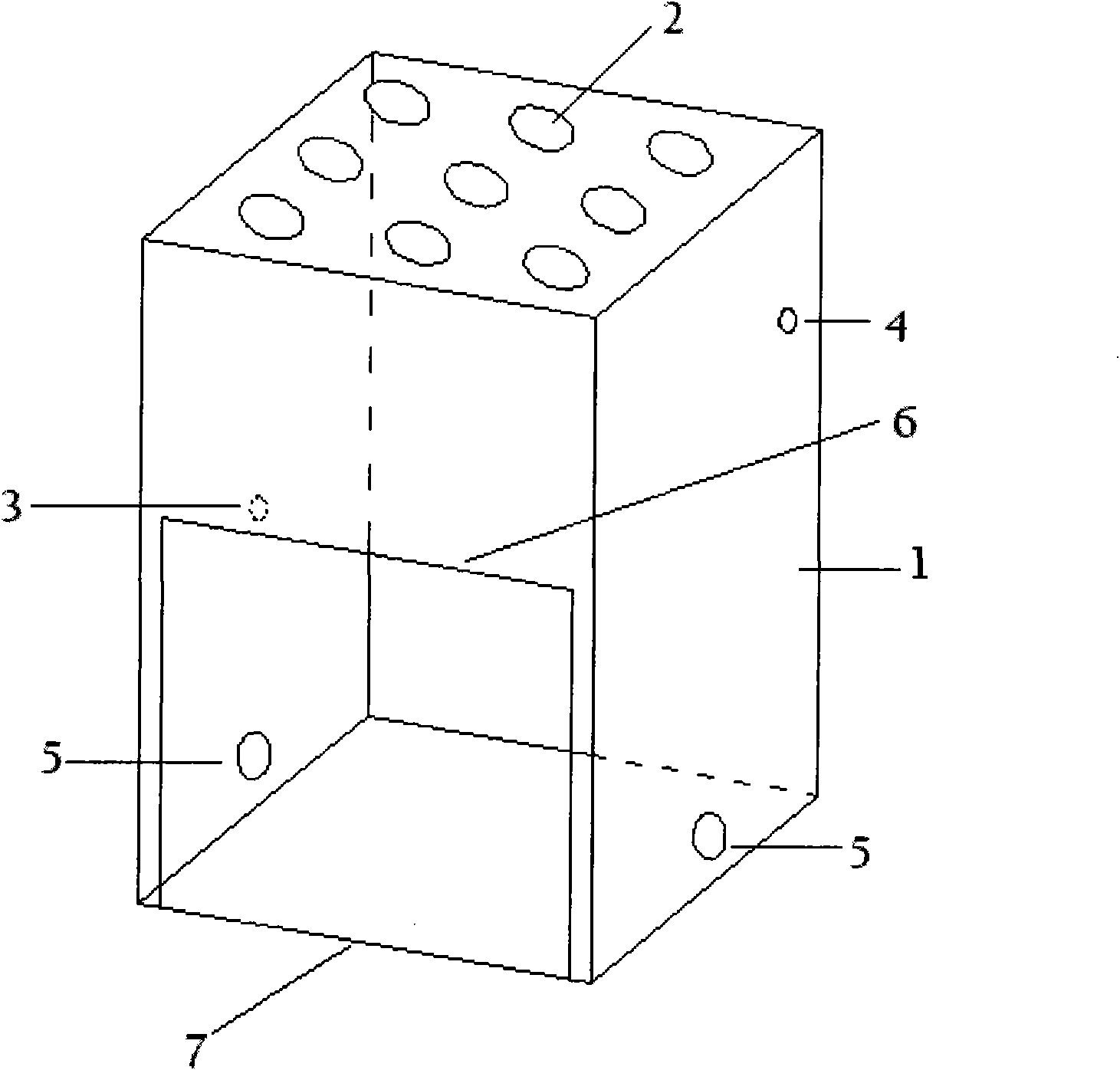

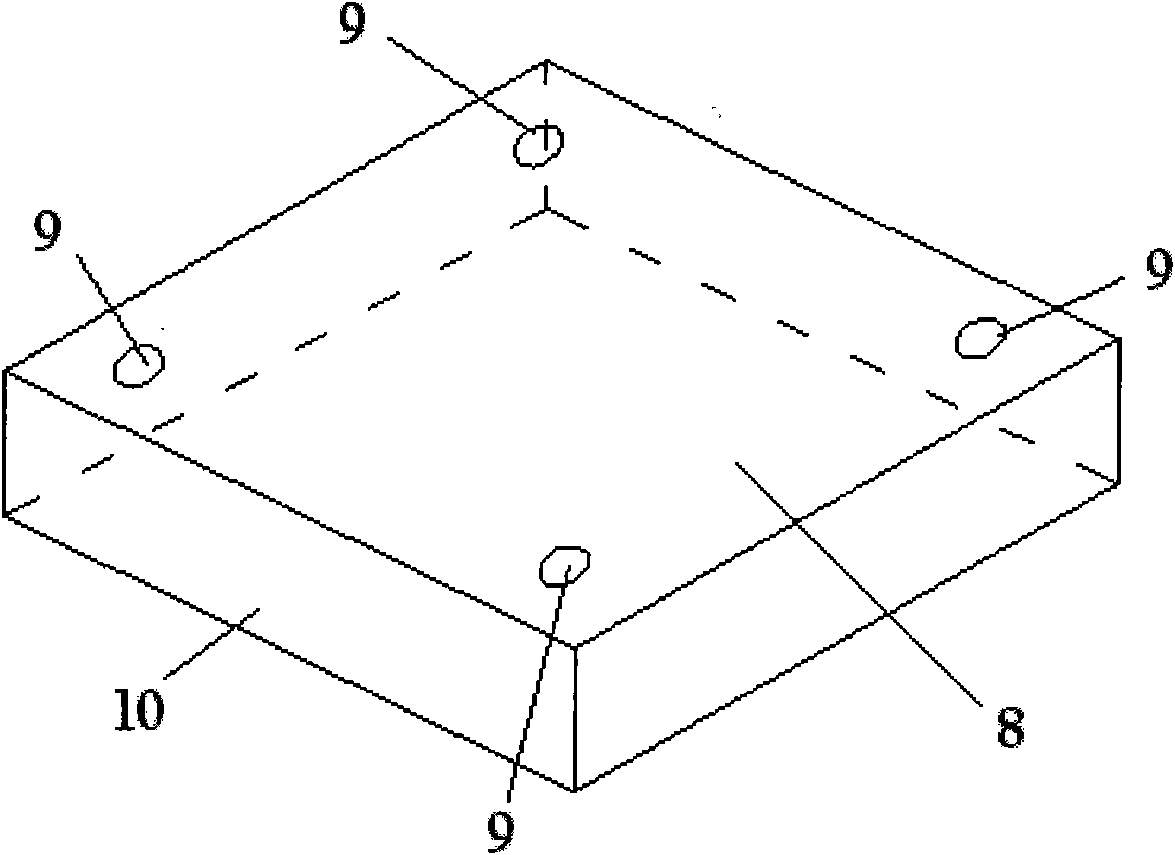

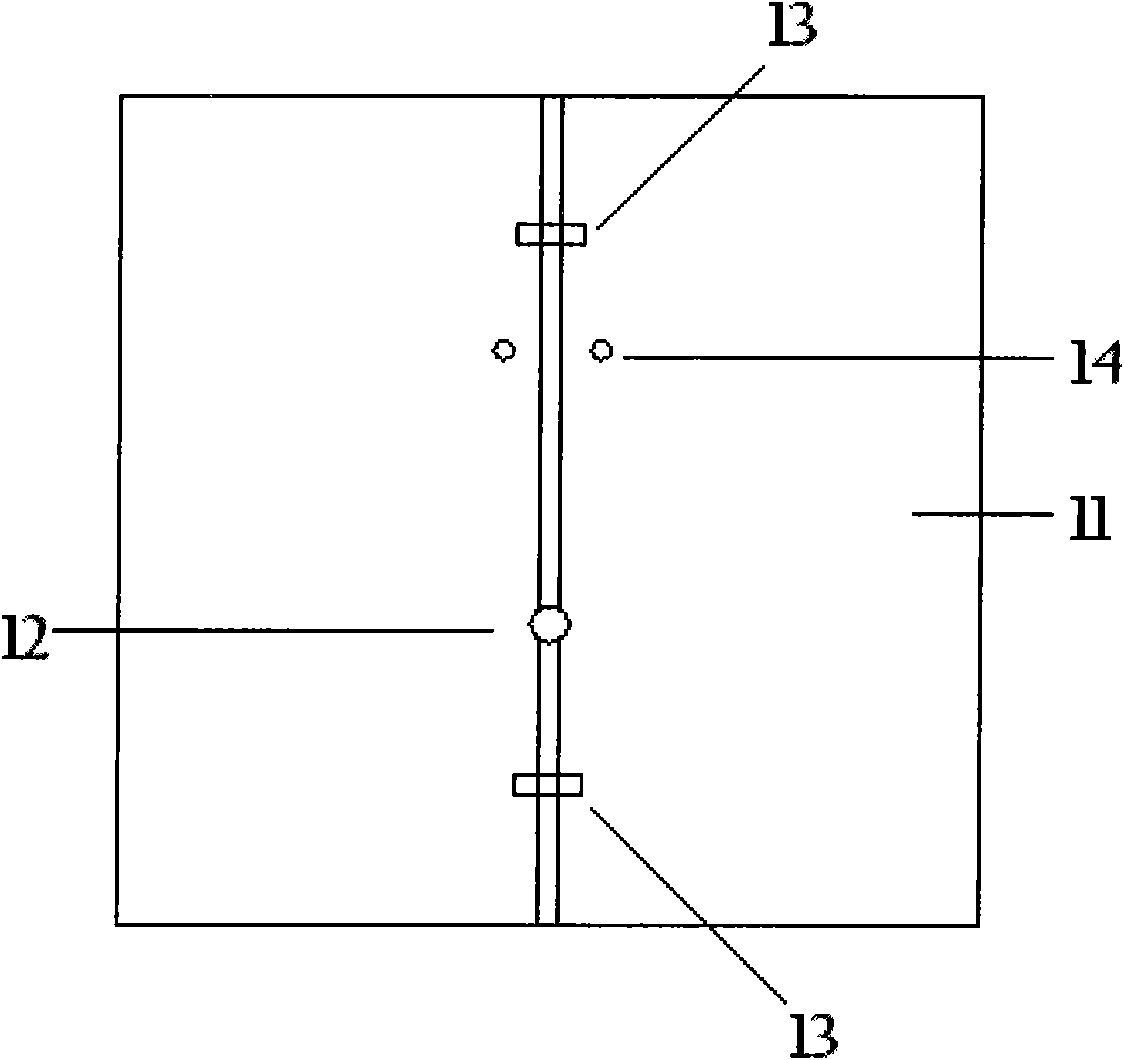

[0026] The main box 1 is made of 1.5mm thick stainless steel material. There is a space inside the box that can accommodate a 400mm cube container or a space of 400mm×400mm×400mm inside the box. Nine GHF125W-03 reflective black lights are installed on the top of the box. High-pressure mercury lamp 2, the right side of the box near the top has an aperture 4 to facilitate the entry a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com