Method for sterilizing air bacterial filter for fermentation tank and fermentation tank provided with air bacterial filter

A sterilization method and fermentation tank technology, applied in the direction of sterilization method, bioreactor/fermentation tank combination, specific-purpose bioreactor/fermentation tank, etc., can solve complex, miscellaneous bacteria pollution, and impure fermentation products and other problems, to achieve the effect of simple structure, easy operation, and simple sterilization operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] Embodiment 1: the sterilizing method of air filter for black fungus liquid fermentation

[0016] Use a fermenter with an air filter installed above the fermentation liquid, fill the tank with black fungus liquid fermentation culture liquid, close the valve, and sterilize the fermenter, maintain it at 123°C for 45 minutes, and complete the sterilization of the air filter at the same time . Cool immediately, and when the temperature drops to 25°C, inoculate black fungus strains, open the valve to ventilate, and start fermentation; ferment for 72 hours, and when the fermentation is over, close the valve.

Embodiment 2

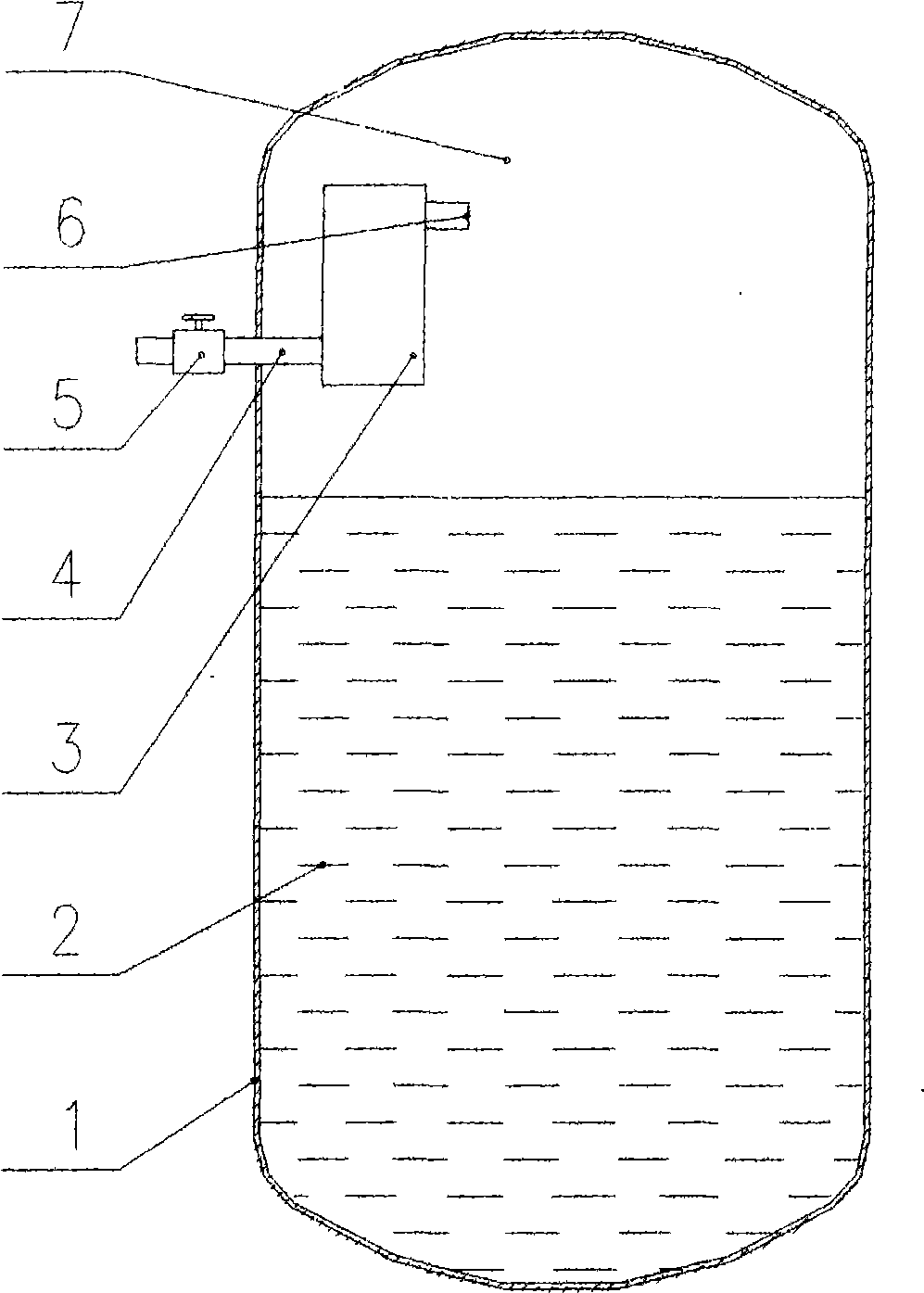

[0017] Embodiment 2 see figure 1 . The fermenter of the present invention comprises a fermenter 1, an air filter 3, a pipeline 4, and a valve 5. The fermenter is equipped with an air filter, and the air filter is installed in the cavity 7 above the fermented liquid 2, and the pipeline Vertical to the tank wall of the fermenter, one end of the pipeline communicates with the valve outside the fermenter, and the other end communicates with the air filter of the fermenter. The air hole 6 at the upper end of the air bacteria filter is connected to the required device according to the different bacteria or the needs of the application.

Embodiment 3

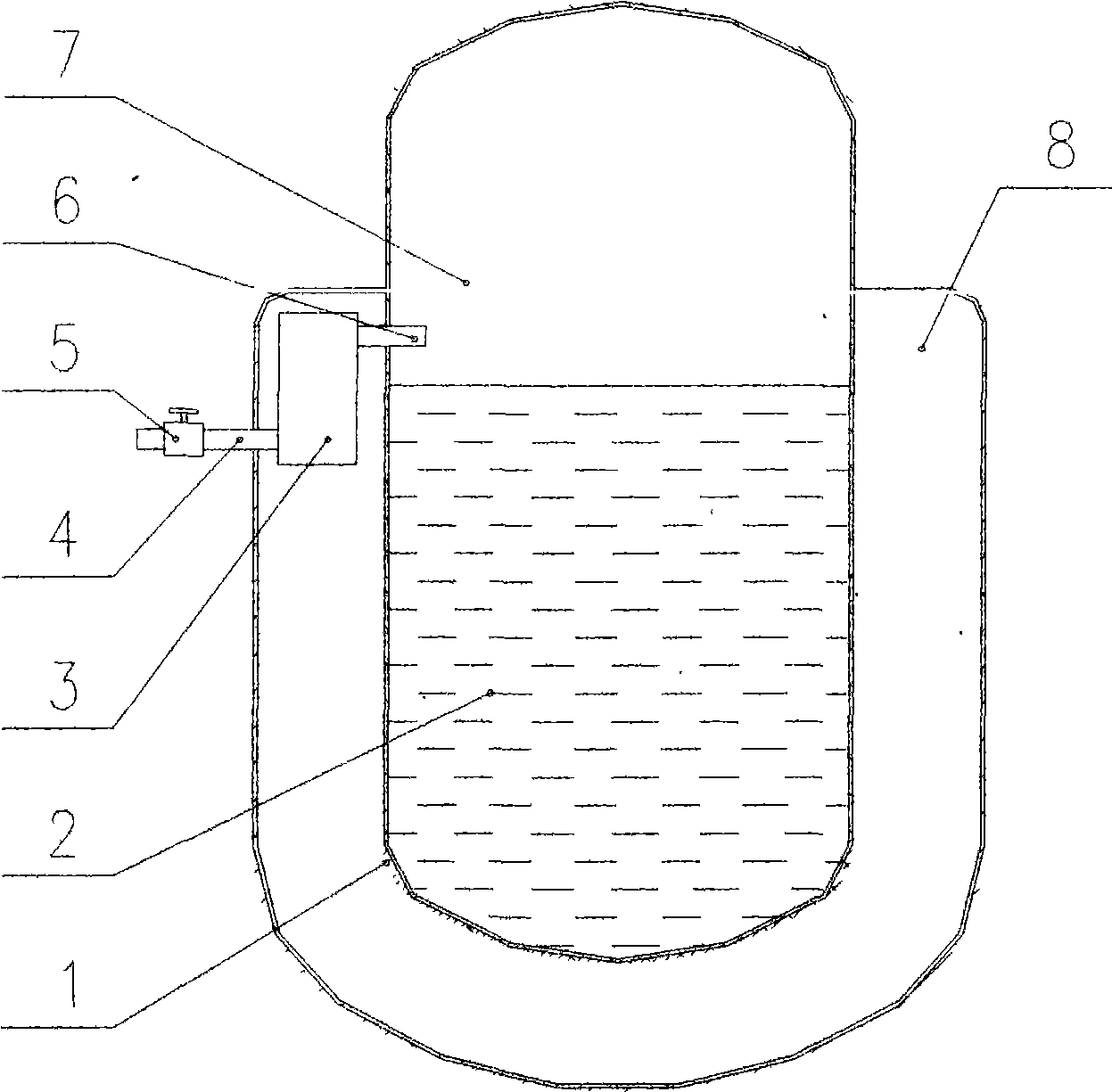

[0018] Embodiment 3: see figure 2 , the fermentor described in embodiment 2, its air bacteria filter is installed in the interlayer 8 outside the fermenter, and described pipeline is perpendicular to the outer wall of the interlayer, and the air hole 6 of the air bacteria filter communicates with the cavity in the fermenter.

[0019] The air bacteria filter used in the embodiment of the present invention is a commercially available air bacteria filter.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap