Automatic exhaust safety transfusion device

A technology of automatic exhaust and infusion set, applied in the field of medical devices, can solve the problems of human injury, complicated and time-consuming, safety hazards, etc., and achieve the effect of avoiding gravity impact, preventing bubble formation, and ensuring safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

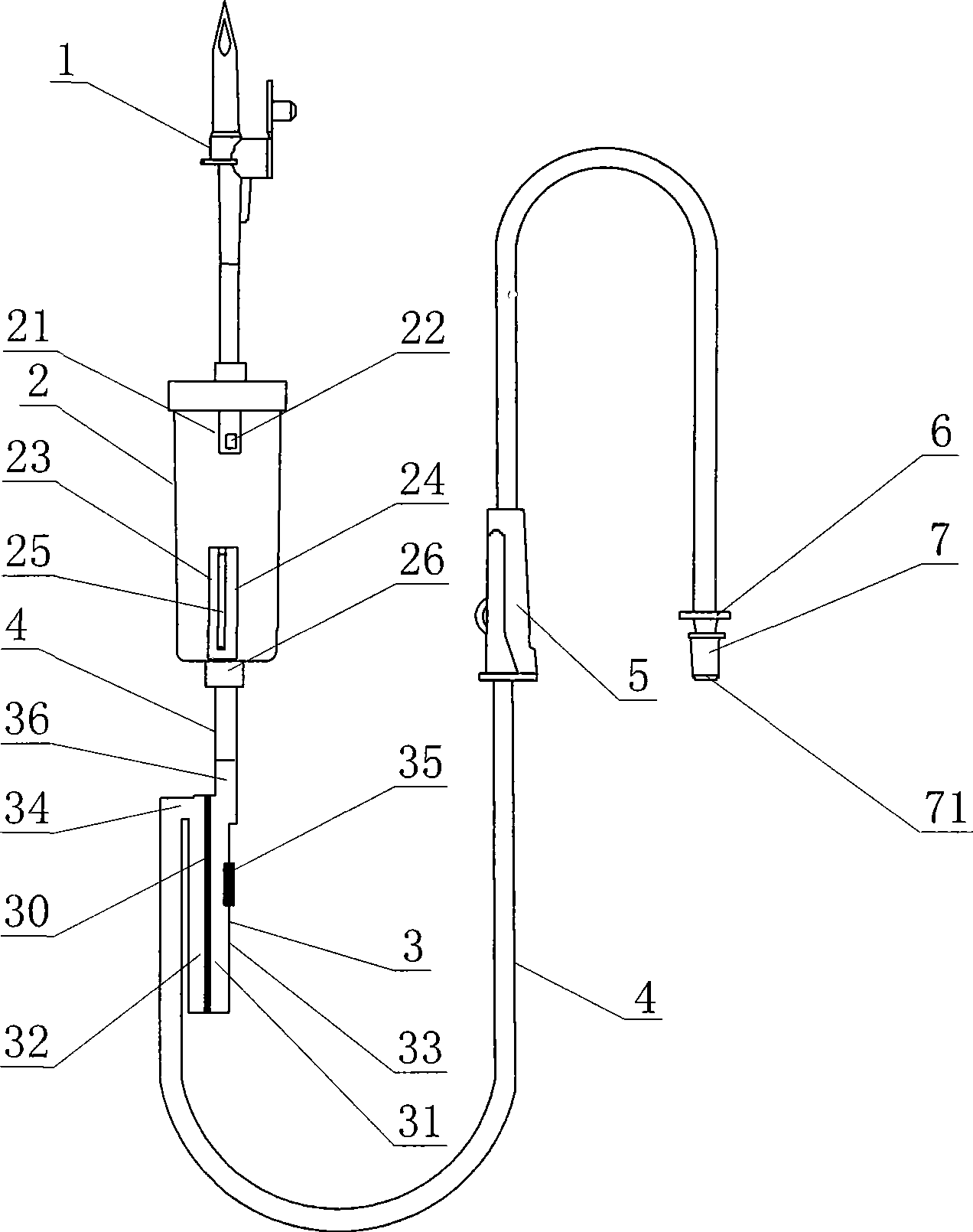

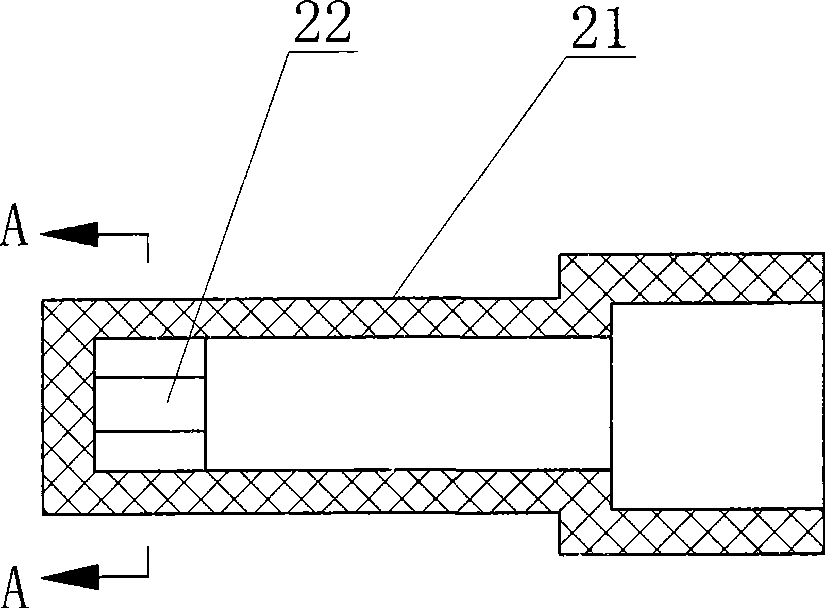

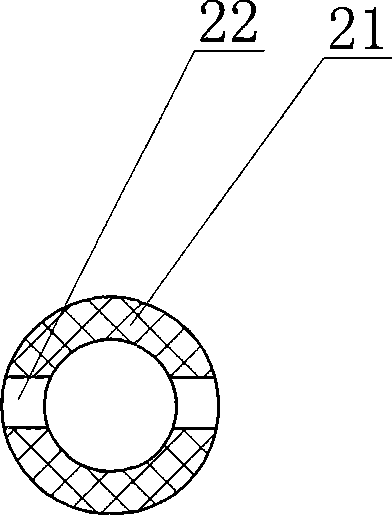

[0018] Such as Figure 1 to Figure 7 As shown, the automatic exhaust safety infusion set of the present invention includes a cork piercer 1, a drip funnel 2 and a conduit 4 communicated with the lower end of the drip funnel 2, a filter 3 installed on the conduit 4 and an adjustment Device 5, in order to make the present invention only need to complete a bottle inserting action to realize automatic air removal in use, without manually operating the exhaust, so as to make its operation more convenient, the lower end of the dripping funnel 2 is installed with a dripping device extending upwards. The lower end of the inner cavity of the bucket 2 is connected to the exhaust pipe 23 of the conduit 4. At least one exhaust infusion hole 25 is provided on the wall 24 of the exhaust pipe 23, and the filter 3 is installed between the dripping funnel 2 and the pipe wall 24. On the conduit 4 between the regulators 5, the filter 3 includes a filter chamber that separates the inner cavity in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com