Low-dimensional nanophase material high-flexibility assembling chip and application method

A low-dimensional nanotechnology, high flexibility technology, applied in nanotechnology, nanotechnology, nanostructure manufacturing and other directions, can solve the problems of poor flexibility, difficulty in realizing three-dimensional control of a single nanomaterial, complex manufacturing process, etc., and achieve the effect of overcoming complex structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

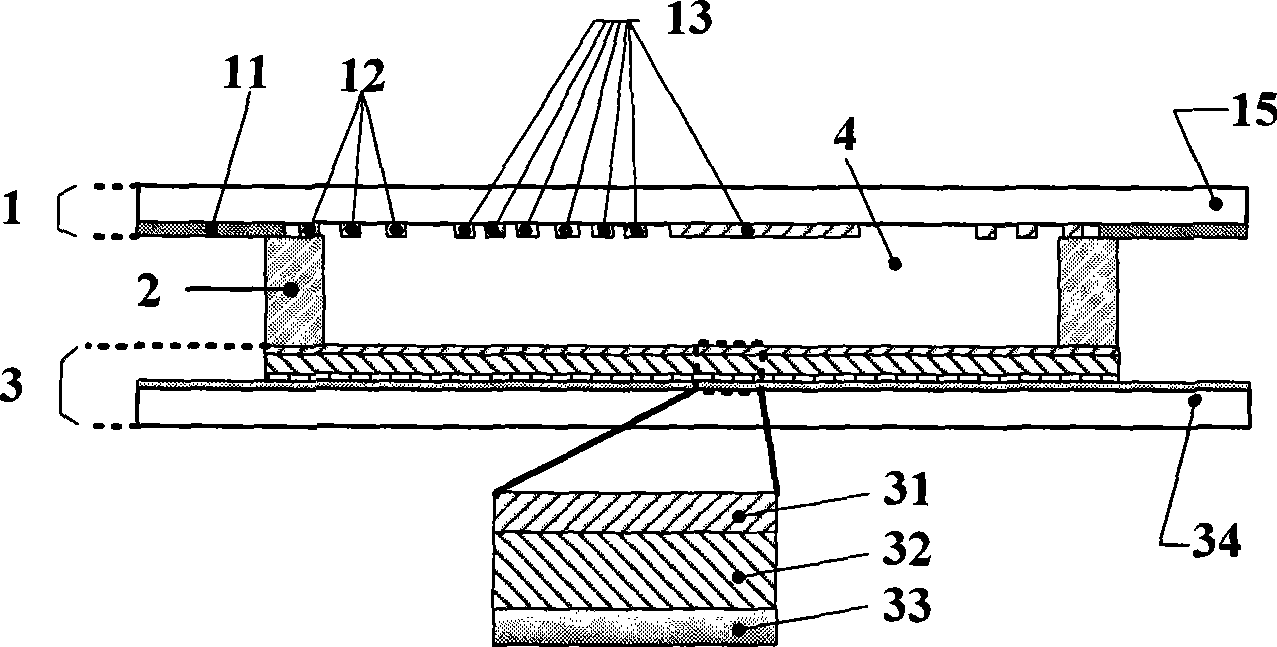

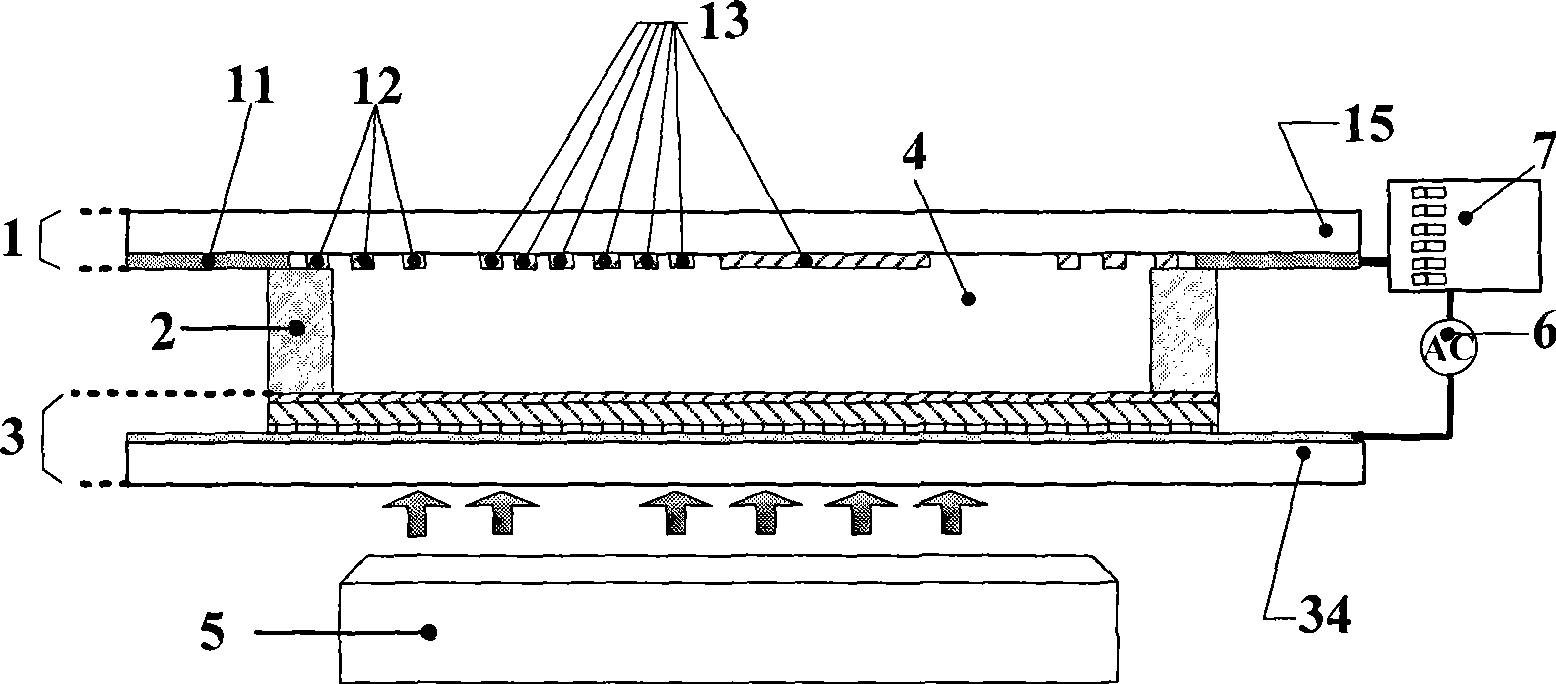

[0029] The embodiment of the highly flexible active assembly chip based on three-dimensional dielectrophoresis low-dimensional nanomaterials provided by the present invention can be found in figure 1 , figure 2 and image 3 . The method of assembling the chip structure, material and configuration of the chip peripheral components is not limited to this embodiment.

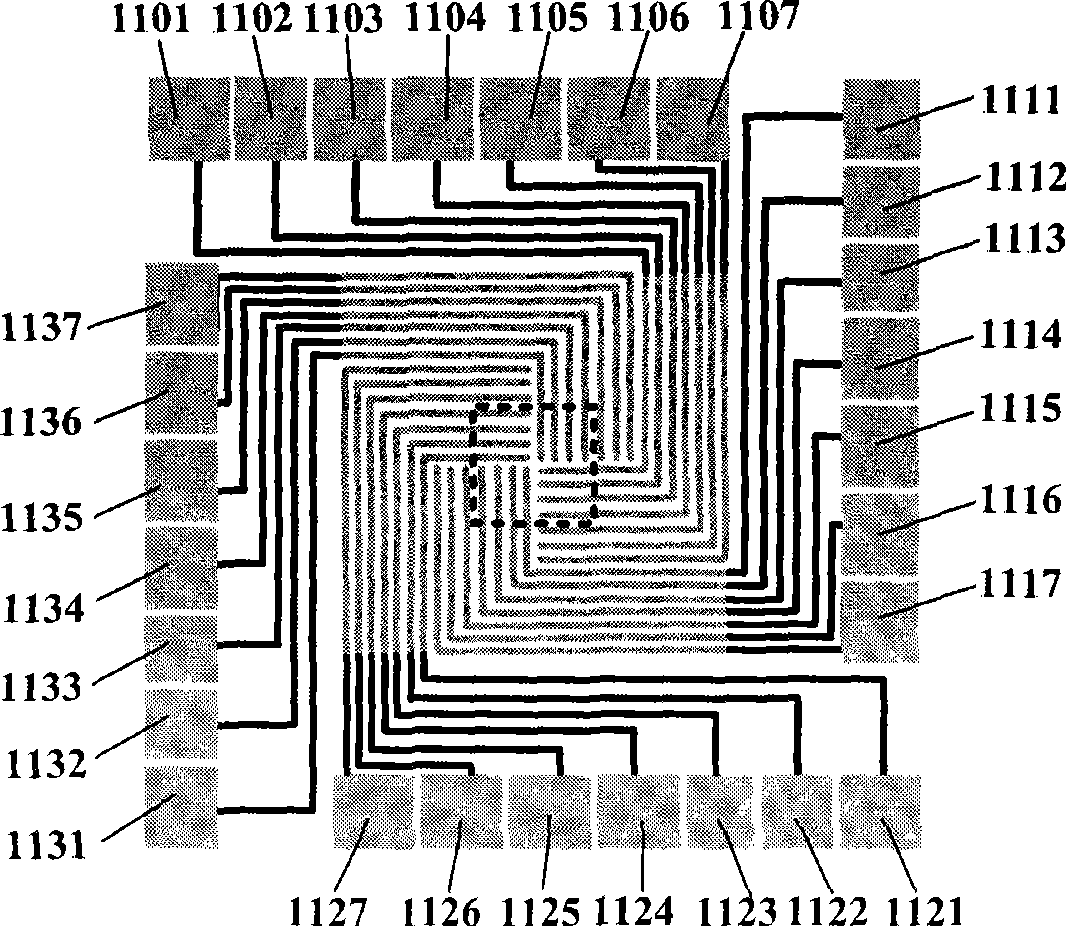

[0030] In this embodiment, the structure of the assembly control chip used for nanomaterial assembly is as follows figure 1 shown. The assembled control chip is composed of an upper substrate 1 , a spacer layer 2 and a lower substrate 3 . The microelectrode array 13 , leads 12 and pins 11 are located on the lower surface of the upper substrate 1 and between the upper transparent substrate 15 and the microfluidic chamber 4 . The lower substrate is composed of an insulating layer 31 , a photoconductive layer 32 , an indium tin oxide film 33 and a lower transparent substrate 34 . The microelectrode array 13 exte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com