A/O denitrification sewage treatment process and device capable of realizing sludge reduction

A sewage treatment device and sludge reduction technology, which is applied to the combined process and device of sewage treatment and the reconstruction of sewage treatment plants, can solve the problem of high sludge output, and achieve the effects of convenient operation and management, simple process flow and investment saving.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

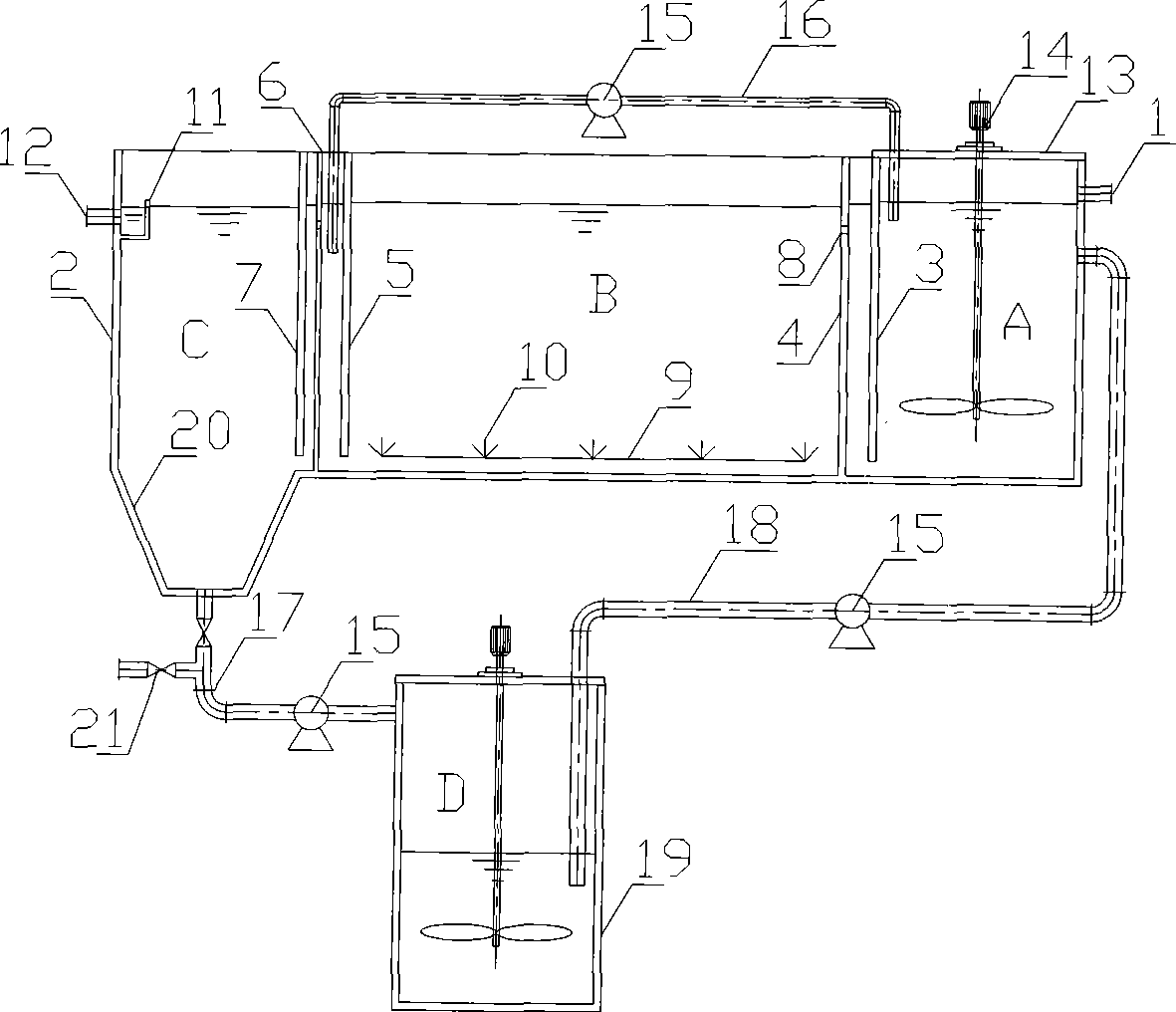

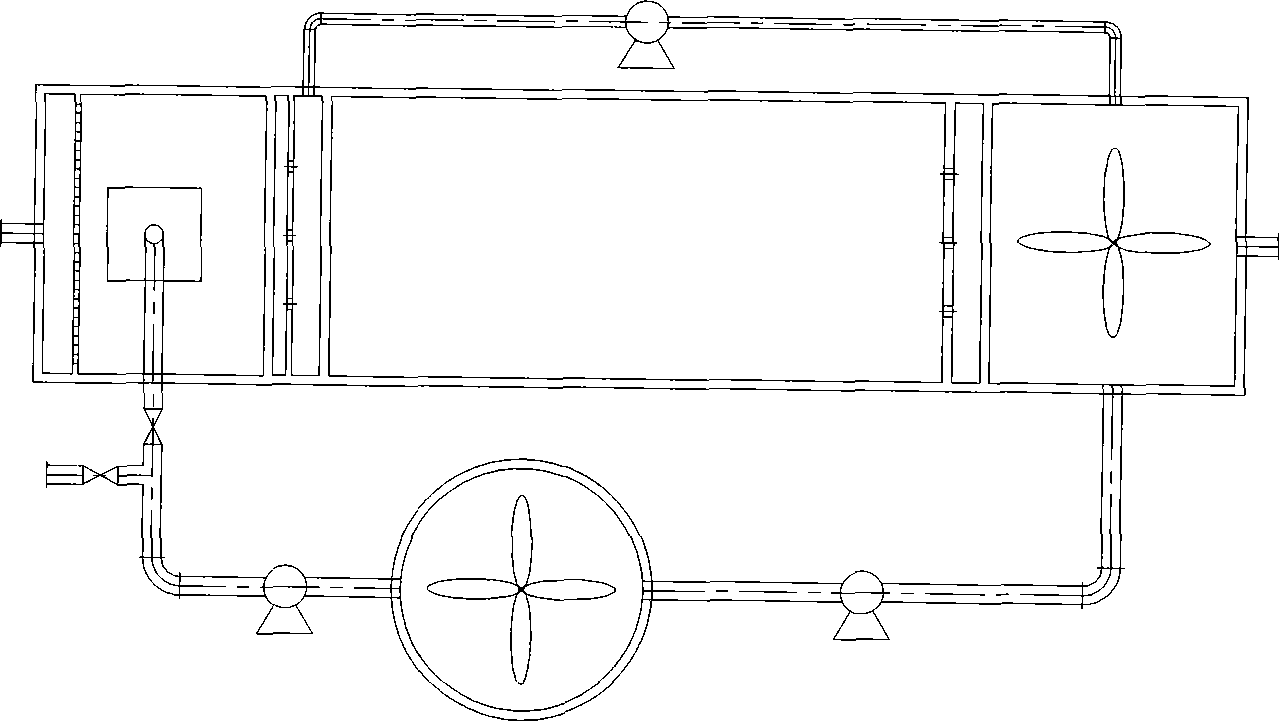

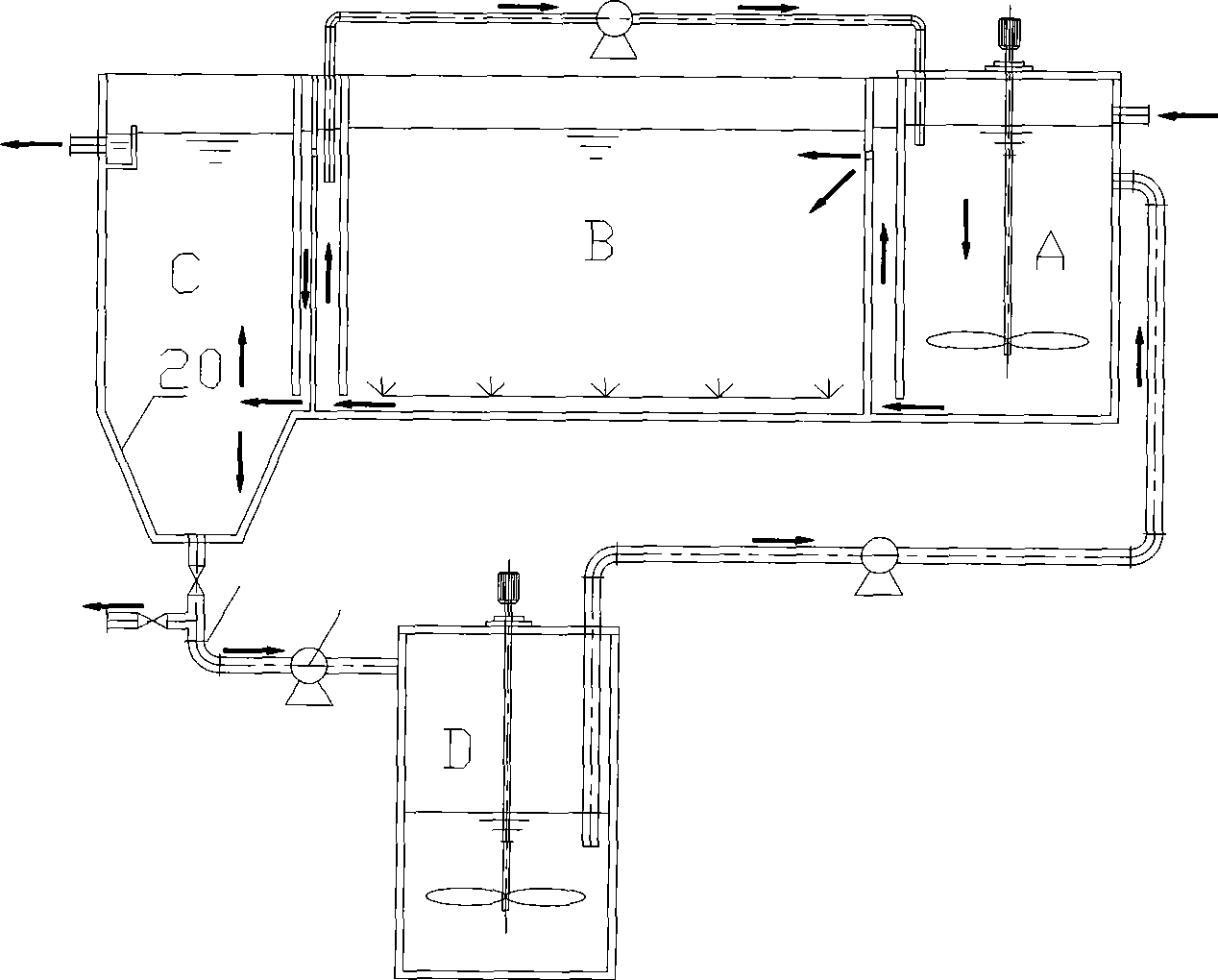

[0027] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0028] The A / O denitrification sewage treatment process of sludge reduction of the present invention has the following processing steps:

[0029] (1) Introduce the sewage to be treated into the anoxic zone, and keep stirring so that the sewage to be treated is fully mixed with the activated sludge returned from the sludge retention tank in step (4), and denitrification is realized in this zone;

[0030] (2) The sewage treated in step (1) is introduced into the aeration zone from the anoxic zone through the transition zone, and the aeration zone is provided with fillers to combine the activated sludge with the suspended growth of microorganisms and the fixed growth of biofilm, and pass through Continuous aeration or intermittent aeration aerates the sewage entering the aeration zone;

[0031] (3) According to the reflux ratio of the mixed liquid, part of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com