Method and special equipment for preparing carbon fiber product

A carbon fiber and product technology, which is applied in the field of resin-based composite material preparation, can solve the problems of difficult air bubbles, low production efficiency, and difficult storage, etc., and achieve the effects of accelerating resin flow, improving work efficiency, and improving impregnation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

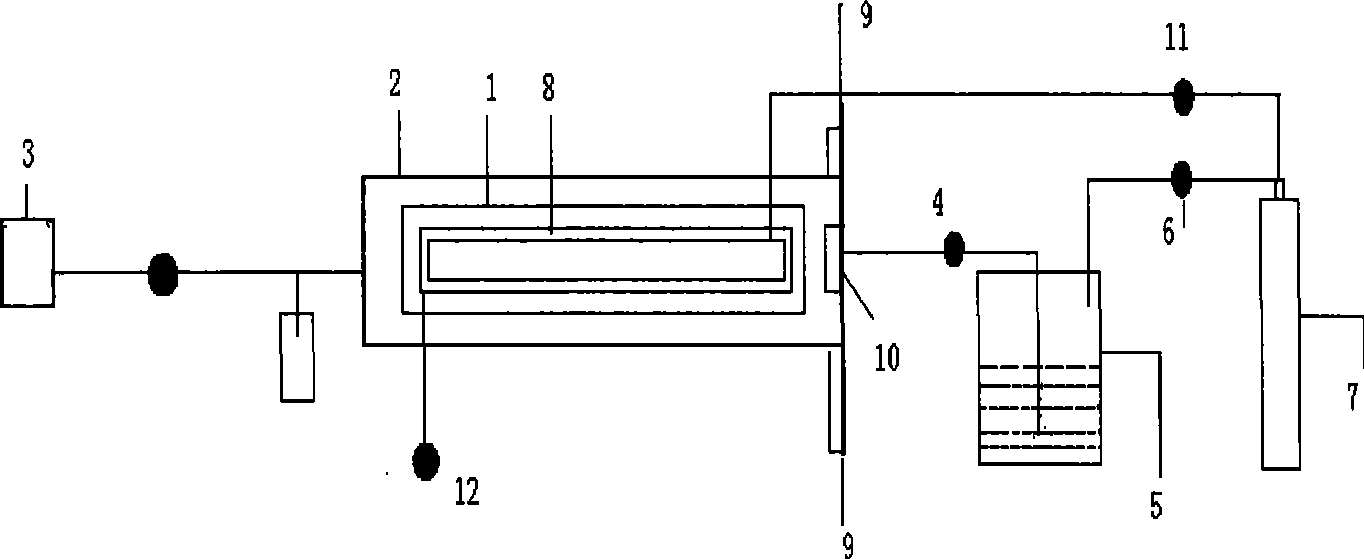

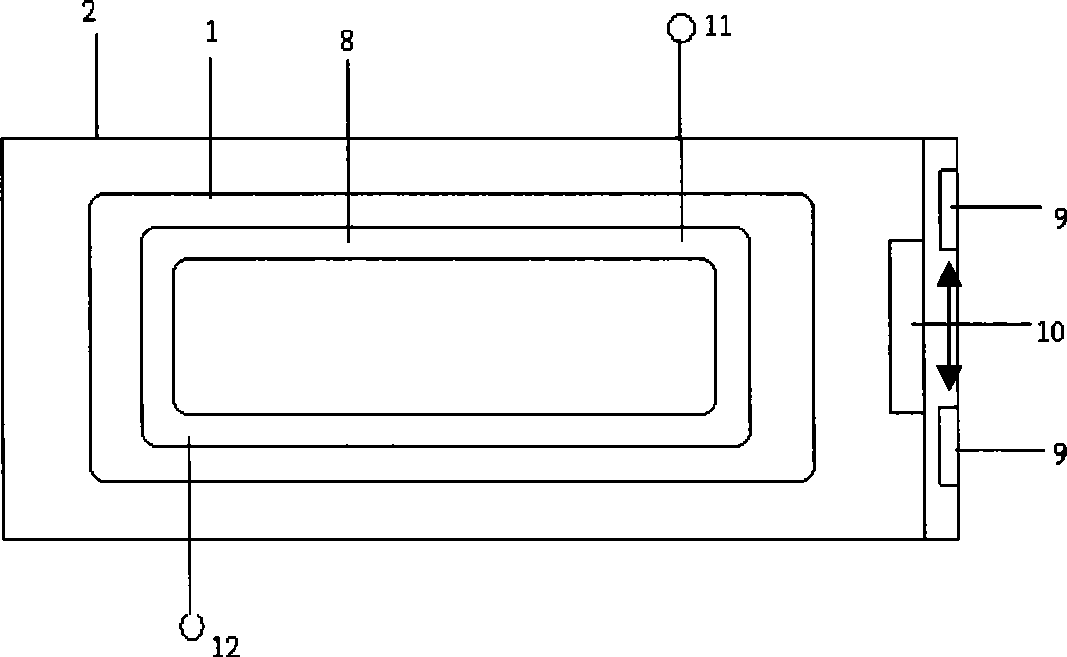

[0022] Lay a layer of carbon fiber cloth between two pieces of tempered glass (1), and then place the tempered glass (1) sandwiched with carbon fiber cloth in the two elastic expandable elastic plates arranged symmetrically up and down inside the diversion sealing device (2). Between the balloons (8), seal the diversion sealing device (2), then place the diversion sealing device (2) on the shelf at a 45-degree inclination angle, and then turn on the vacuum pump (3), and the diversion sealing device (2) Carry out vacuuming, open the heating device (10) in the diversion sealing device (2), make the temperature reach 80°C, then open the resin tank valve (4), extract resin from the sealed resin tank (5), and adjust the flow direction of the resin device (9) to adjust the flow direction and flow rate of the resin, observe the resin entering between the two pieces of tempered glass (1) in the diversion sealing device (2) through the transparent visible window on the diversion sealing...

Embodiment 2

[0024] Lay a layer of carbon fiber cloth between two pieces of tempered glass (1), and then place the tempered glass (1) sandwiched with carbon fiber cloth in two symmetrically arranged square frames inside the diversion sealing device (2). Between the elastic inflatable balloons (8), seal the diversion sealing device (2), then place the diversion sealing device (2) on a shelf with an inclination angle of 30 degrees, and then turn on the vacuum pump (3), and seal the diversion sealing device (2). (2) Carry out vacuuming, open the heating device (10) in the diversion sealing device (2), make the temperature reach 90°C, then open the resin tank valve (4), and then open the pressurization valve (6) to use compressed gas ( 7) Pressurize the resin tank, extract resin from the sealed resin tank (5), adjust the resin flow to the controller (9), adjust the flow direction and flow rate of the resin, and pass through the transparent visible window on the diversion sealing device (2) Obs...

Embodiment 3

[0026]Lay a layer of carbon fiber cloth between the two pieces of tempered glass (1), and then place the tempered glass (1) sandwiched with carbon fiber cloth in the two circular springs arranged symmetrically up and down inside the diversion sealing device (2). Between the inflatable balloons (8), seal the diversion sealing device (2), then place the diversion sealing device (2) on the shelf at a 60-degree inclination angle, then turn on the vacuum pump (3), to the diversion sealing device ( 2) Carry out vacuuming, open the heating device (10) in the diversion sealing device (2), make the temperature reach 40°C, then open the resin tank valve (4), then open the pressurization valve (6) and use compressed gas (7 ) to pressurize the resin tank, extract resin from the sealed resin tank (5), adjust the resin flow to the controller (9), adjust the flow direction and flow rate of the resin, and observe through the transparent visible window on the diversion sealing device (2) When ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com