Solid rocket engine

A technology of solid rockets and motors, which is applied in the direction of rocket motor devices, machines/engines, mechanical equipment, etc. It can solve the problems of reducing thrust, reducing charge, reducing volume, etc., and achieves large combustion surface area, short working time and high reliability. Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

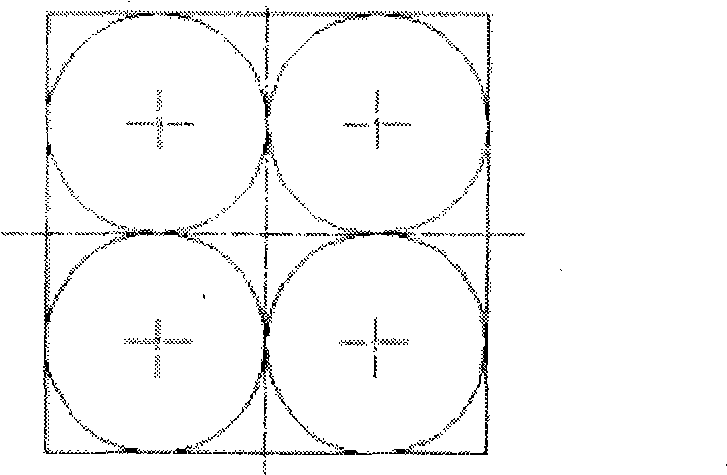

[0015] refer to figure 1 , the engine layout is to arrange four centrally symmetrical small engines of the same size in a given space, and every two centrally symmetrical engines form a group to realize orbital maneuvering of the satellite. When the first orbit change is required by the ground command, the two centrally symmetrical engines will be ignited to make the satellite enter the transfer orbit from the original orbit; when the satellite moves to the entry point with the target satellite orbit, the other two The engine is ignited to put the satellite into the target satellite orbit. Two centrally symmetrical engines are used to ignite to realize the layout of orbital maneuvering, which requires high machining accuracy of the engines, good ignition reliability, and consistency in timing of the ignition commands issued by the ignition control device for the two engines. better.

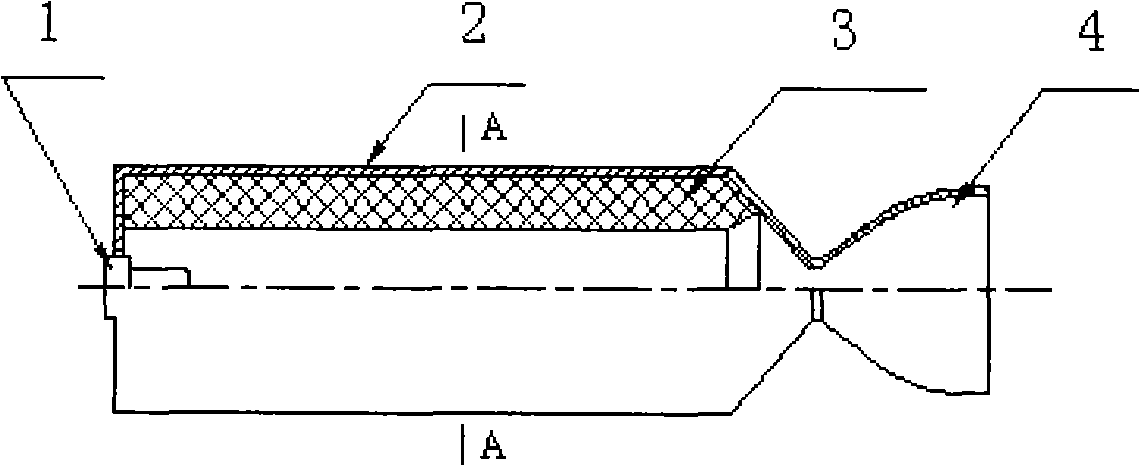

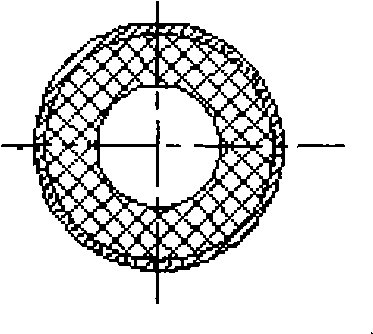

[0016] refer to figure 2 , the engine is composed of an igniter 1, a casing 2, a propella...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com