Automobile engine cooling fan control system based on four-phase double-wire winding brushless DC motor

A technology of brushed DC motors and bifilar windings, which is applied in pump control, mechanical equipment, machines/engines, etc., can solve the problems of low utilization rate of motors, and achieve the effects of improving efficiency, reducing costs, and facilitating control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

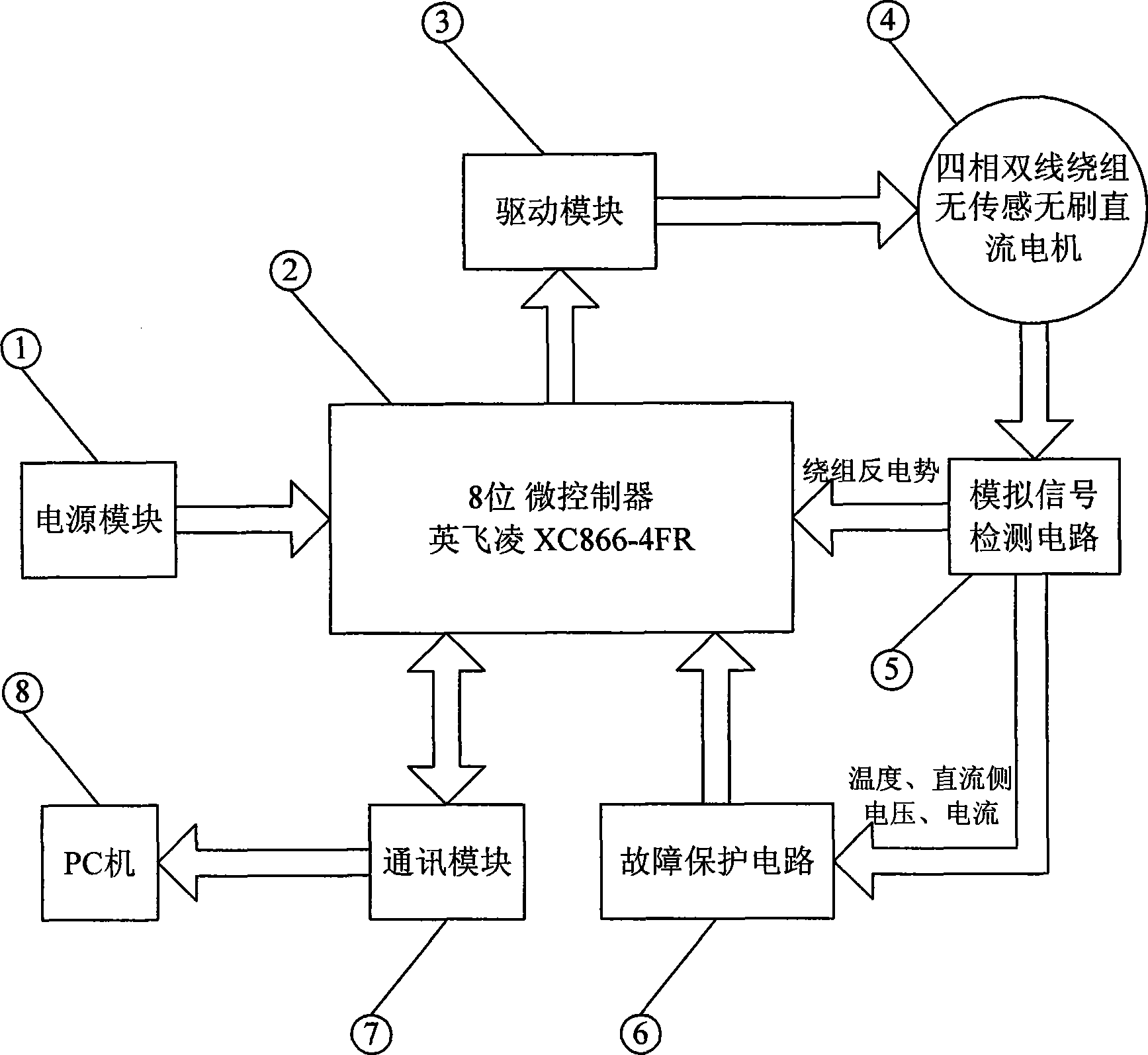

[0030] In conjunction with the accompanying drawings, the present invention is described as follows: The automotive engine cooling fan control system based on the four-phase two-wire winding brushless DC motor includes the following hardware and software.

[0031] Hardware of Automotive Engine Cooling Fan Control System Based on Four-phase Two-wire Winding Brushless DC Motor

[0032] Such as figure 1As shown, the automotive engine cooling fan control system based on the four-phase two-wire winding brushless DC motor proposed by the present invention mainly includes a microcontroller 2, a controller power module 1, a drive circuit 3, and a four-phase two-wire winding brushless DC motor. Motor 4, analog signal detection circuit 5, fault protection circuit 6, communication interface circuit 7 and PC 8. The output control signal of the microcontroller 2 is connected to the motor 4 through the drive module 3, thereby controlling the motor 4; the analog signal detection circuit 5 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com