Absorption type water cooling and warming machine

A cold and warm water machine and absorption type technology are applied in the field of single-effect absorption cold and warm water machines, which can solve the problems of inability to operate with warm and hot supply, and can not operate with cold and heat supply, and achieve the effect of simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] Hereinafter, the present invention will be described in detail with reference to the accompanying drawings.

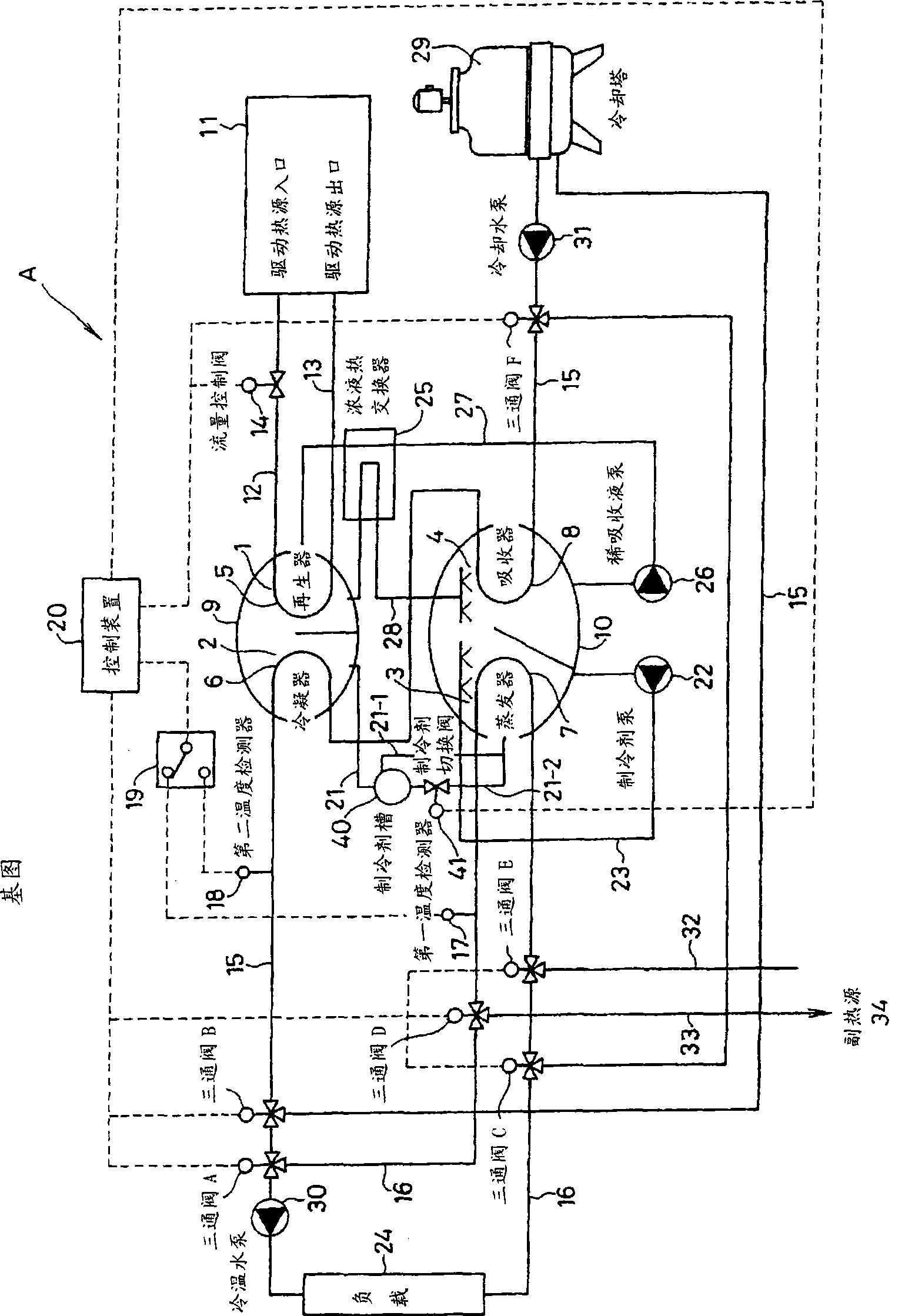

[0039] figure 1 It is an explanatory drawing explaining one Embodiment of the whole absorption-type water cooler and warmer of this invention.

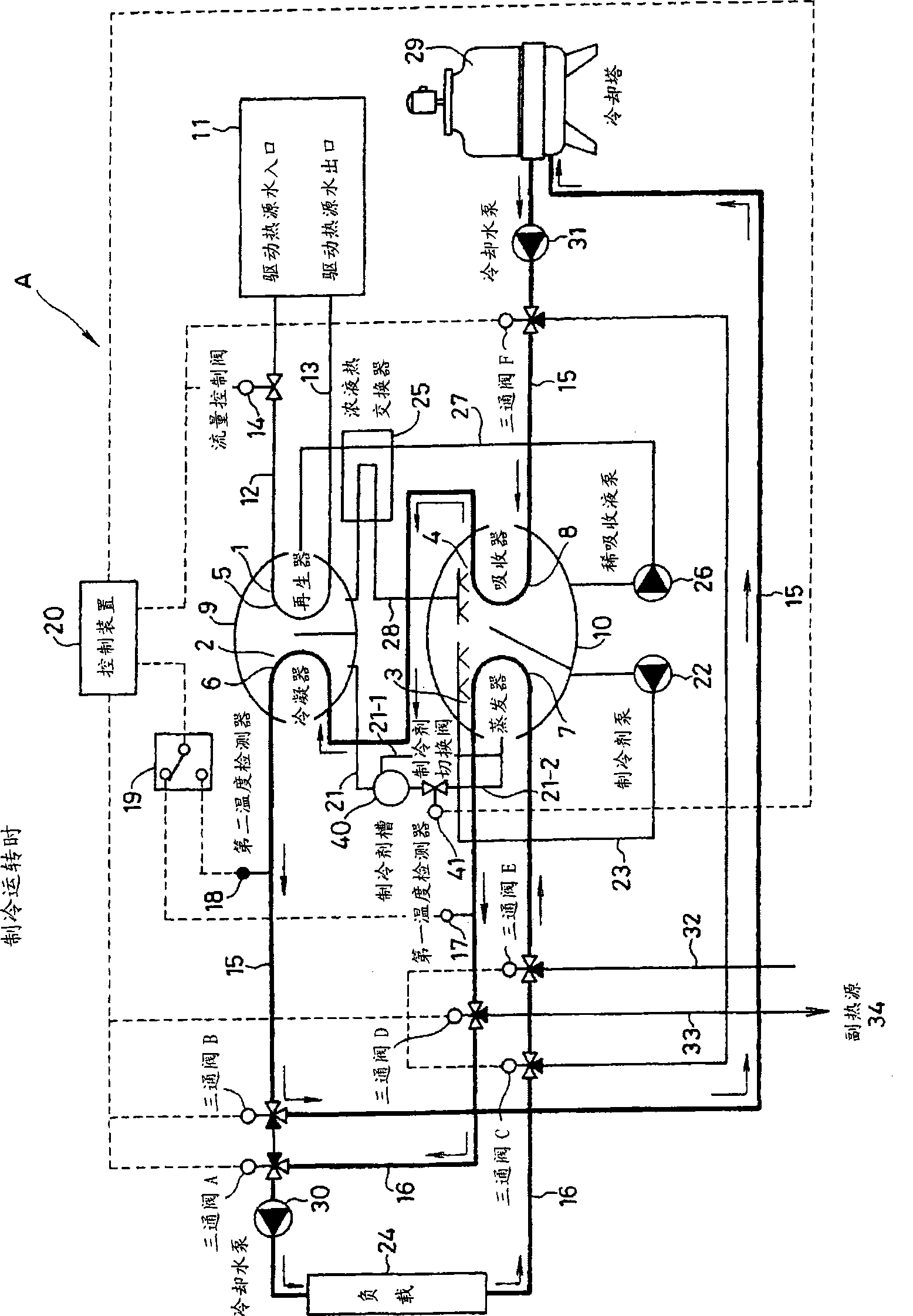

[0040] figure 2 is to illustrate the use of figure 1 It is an explanatory diagram showing an embodiment of the absorption-type chiller and warm-water machine of the present invention performing a cooling operation.

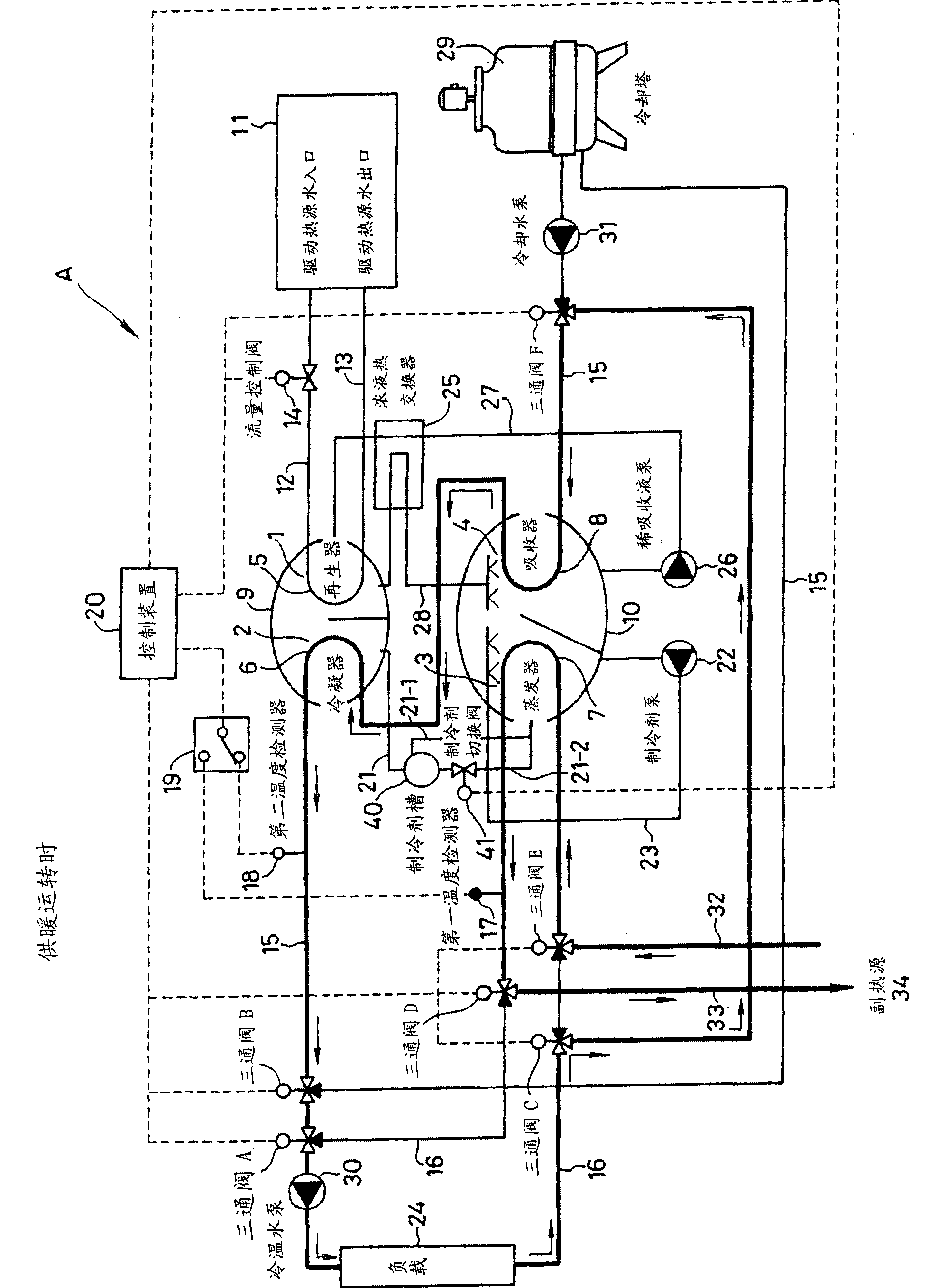

[0041] image 3 is to illustrate the use offigure 1 It is an explanatory diagram showing an embodiment of the absorption-type chiller and warm water machine of the present invention when it performs a heating operation.

[0042] figure 1 The parts indicated by the reference numerals in the figure 2 and image 3 in the same. In use figure 2 Description and use of the absorption-type water chiller of the present invention in cooling operation image 3 These will be described when explaining the c...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap