Method for manufacturing silicon rubber compound insulator

A technology for composite insulators and manufacturing methods, which is applied in the direction of insulators, suspension/strain insulators, electrical components, etc., and can solve problems such as differences in processing and manufacturing processes, affecting the structural stability of insulators, and poor antifouling performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

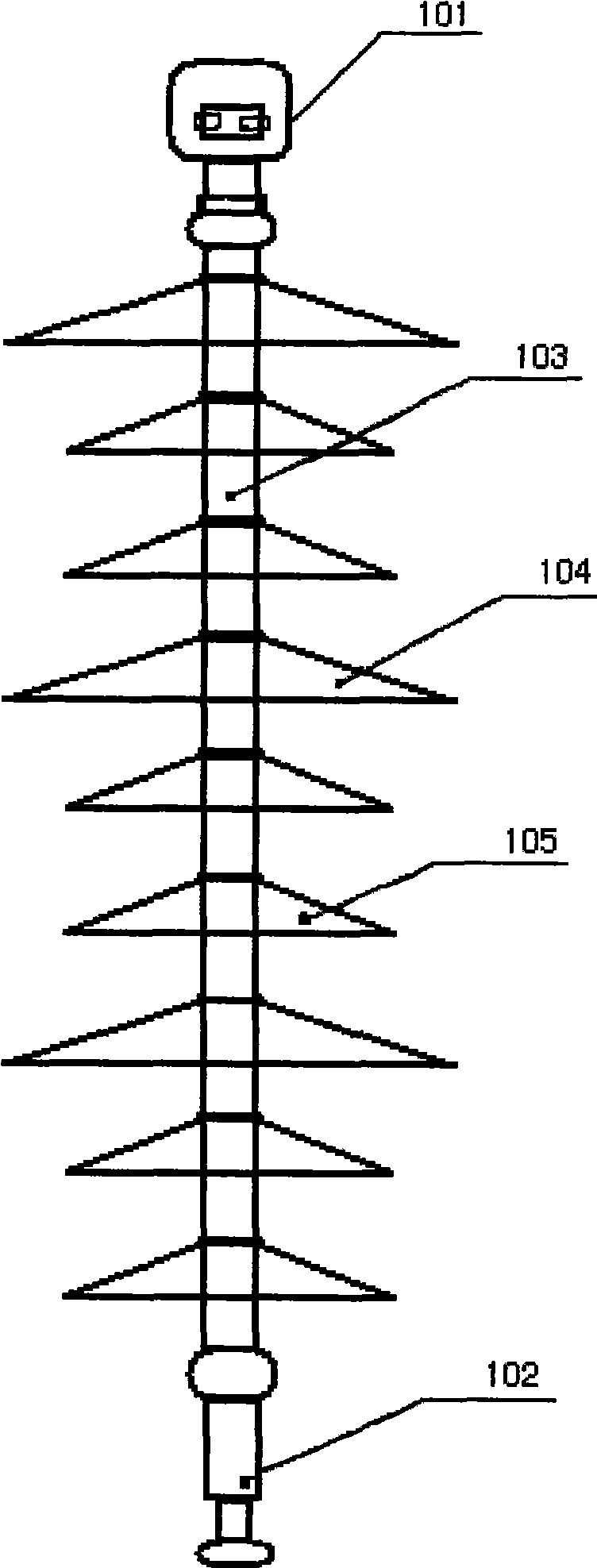

[0020] Take the suspension silicone rubber composite insulator as an example, such as figure 1 As shown, it includes an upper end fitting 101 and a lower end fitting 102 with jacks, an epoxy glass fiber mandrel 103, a large silicone rubber shed 104 and a small silicone rubber shed 105, the upper end fitting 101 is an elbow structure, The lower fitting 102 is a ball head structure;

[0021] Wherein, the two ends of the epoxy glass fiber mandrel 103 are respectively inserted into the sockets of the upper fitting 101 and the lower fitting 102 and are respectively crimped and connected with the upper fitting 101 and the lower fitting 102, and the large silicone rubber umbrella skirt 104. The small silicone rubber sheds 105 are molded and connected to the epoxy glass fiber mandrels 103 respectively;

[0022] Specifically, its preparation method com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com