Feeding solid complex enzyme and preparation method thereof

A compound enzyme, solid technology, applied in application, animal feed, animal feed, etc., can solve the problems of component enzyme activity and high production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

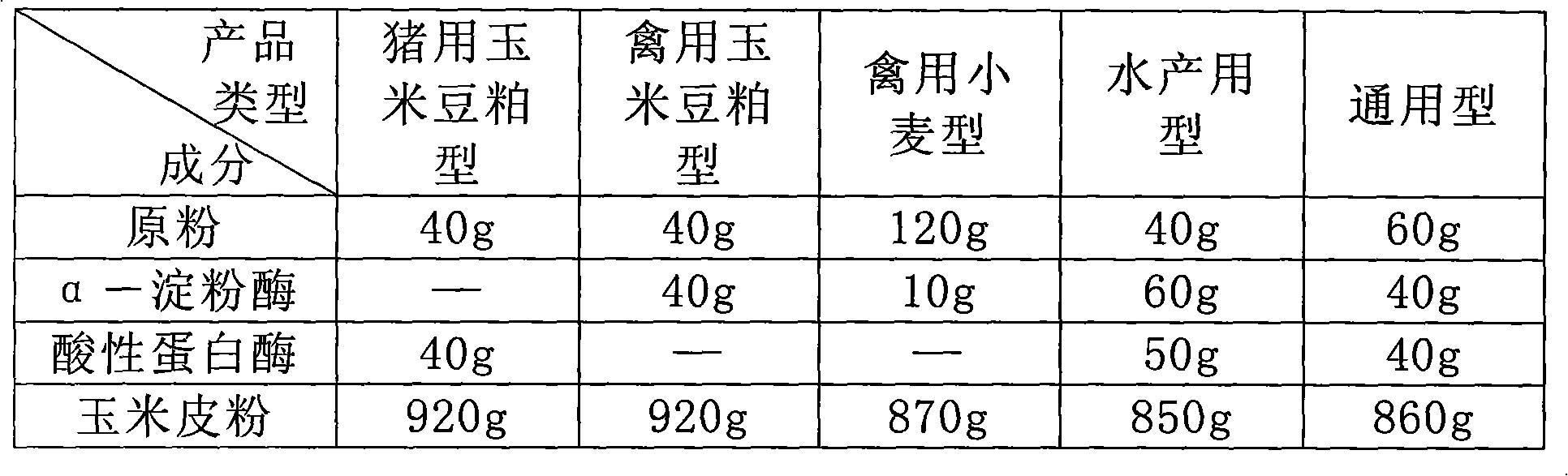

[0019] The preparation method of the solid composite enzyme of the present invention comprises the following steps of preparing the solid composite enzyme for feed by flashing and drying the fermented koji material at low temperature, pulverizing and adding ingredients: 1. After flash drying at 80°C for 5 seconds, crush it into 40-mesh raw powder; 2. Add ingredients to the raw powder according to the formula to prepare the finished solid compound enzyme for feed; the ingredients are acid protease and α-amylase One or two, and corn bran powder; the mass percentage formula of each component is: raw powder: 4-12%, 50000U / g acid protease: 0 or 1-6%, 2000U / g α-starch Enzyme: 0 or 4-5%, corn bran powder: balance; 3. Pack and store the finished product.

[0020] The effective enzyme components of the solid fermented koji are xylanase, pectinase, mannanase, β-glucanase, cellulase, acid protease and α-galactosidase. Each of the following examples is implemented by applying the above-m...

Embodiment 1

[0024] According to the above-mentioned process, according to the formula listed in Table 1, 109kg of solid fermented koji material was flash-dried at a low temperature of 95°C and 80°C for 5 seconds to obtain 70kg of dry material, and pulverized by a pulverizer to obtain 70kg of 40-mesh raw powder. 70kg of 50000U / g acid protease and 1610kg of corn bran powder were used to obtain 1750kg of solid compound enzyme for pig corn and soybean meal type feed. It has been tested that it contains xylanase 45623u / g, pectinase 16918u / g, mannanase 821u / g, β-glucanase 36521u / g, cellulase 558u / g, acid protease 3765u / g, α-galactosidase 378u / g.

Embodiment 2

[0026] According to the above-mentioned process, according to the formula listed in Table 1, 109kg of solid fermented koji material was flash-dried at a low temperature of 95°C and 80°C for 5 seconds to obtain 70kg of dry material, and pulverized by a pulverizer to obtain 70kg of 40-mesh raw powder. 70kg of alpha-amylase of 2000U / g, 1610kg of corn bran powder, obtain the finished product of 1750kg of solid compound enzymes for poultry corn soybean meal type feed. It has been tested that it contains xylanase 45615u / g, pectinase 16887u / g, mannanase 818u / g, β-glucanase 36515u / g, cellulase 562u / g, acid protease 373u / g, α-galactosidase 368u / g, α-amylase 175u / g.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com