An air spring vulcanizing device

An air spring vulcanization and air spring technology, which is applied to other household appliances, household appliances, household components, etc., can solve the problems of long time required for cold setting, unstable product size, low production efficiency, etc., and achieve small deformation and stable size. , the effect of high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

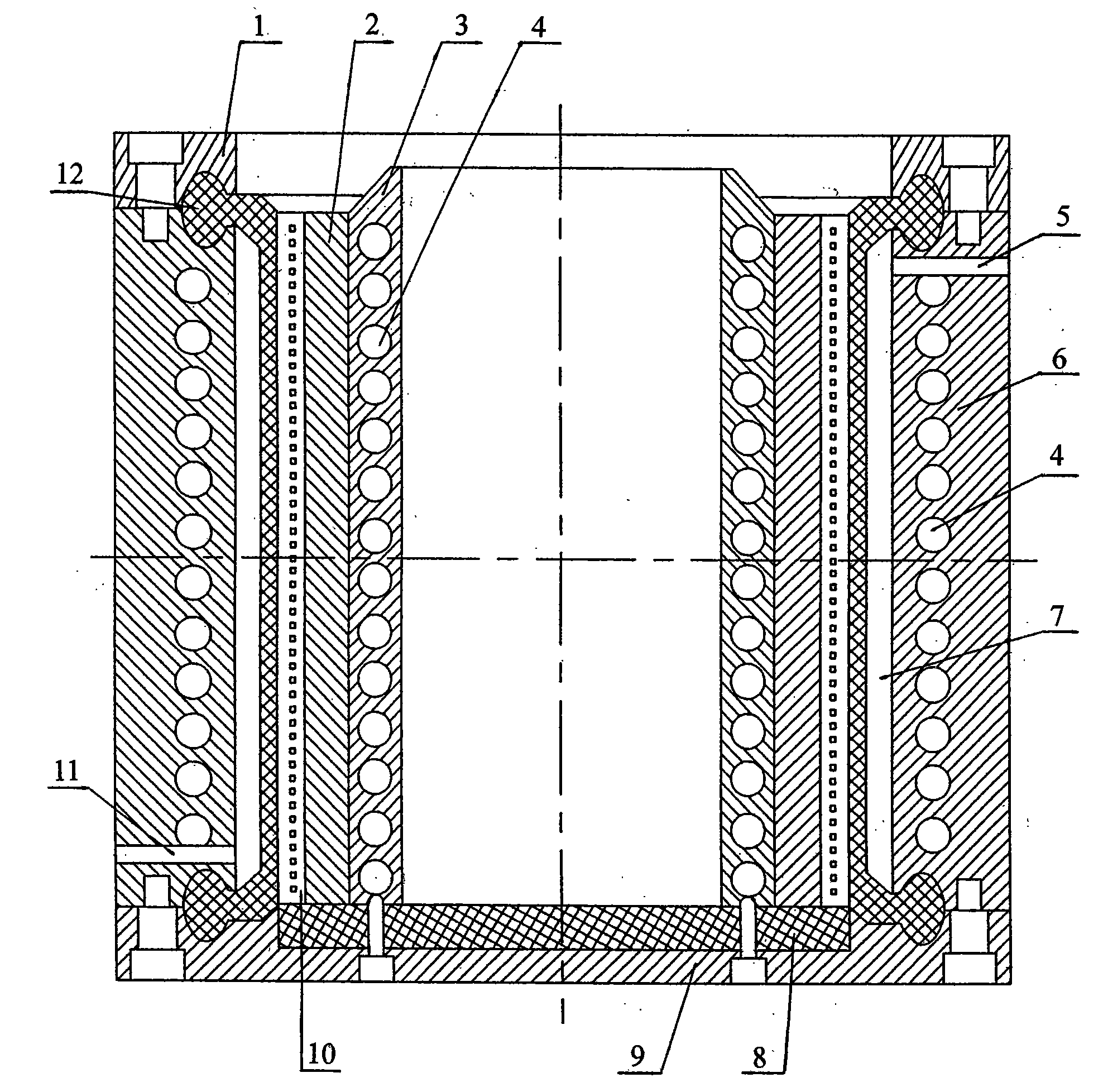

[0014] Air spring vulcanization device, such as figure 1 As shown, it includes screw-connected detachable upper platen 1, outer cylinder 6 and lower platen 9, the three are sealed and fixed, the outer cylinder is provided with a concentrically fitted inner cylinder 3, and the outer cylinder and the inner cylinder are wound with The electric heating chip 4, which can be an electric heating wire or an electric heating tube, is connected to an external power supply, and the heating temperature is controlled by a PLC circuit control system at 150±4°C. A ring-shaped closed vulcanization chamber 7 is formed between the inner and outer cylinders. In the vulcanization chamber, there is a vulcanization drum 2 sleeved outside the inner cylinder 3. In the outer cylinder 6, there are upper cylinders with two ends consisting of an upper pressing plate and an outer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com