Membrane biologic reaction equipment and processing method for processing industrial waste water with high ammoniac nitrogen

A membrane biological reaction and high-ammonia-nitrogen industry technology is applied to membrane bioreactors and treatment fields for high-ammonia-nitrogen industrial wastewater treatment, which can solve the problems of high energy consumption, insignificant effect, accumulation of nitrite, etc., and achieves simple operation and maintenance, The effect of remarkable treatment effect and high denitrification effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

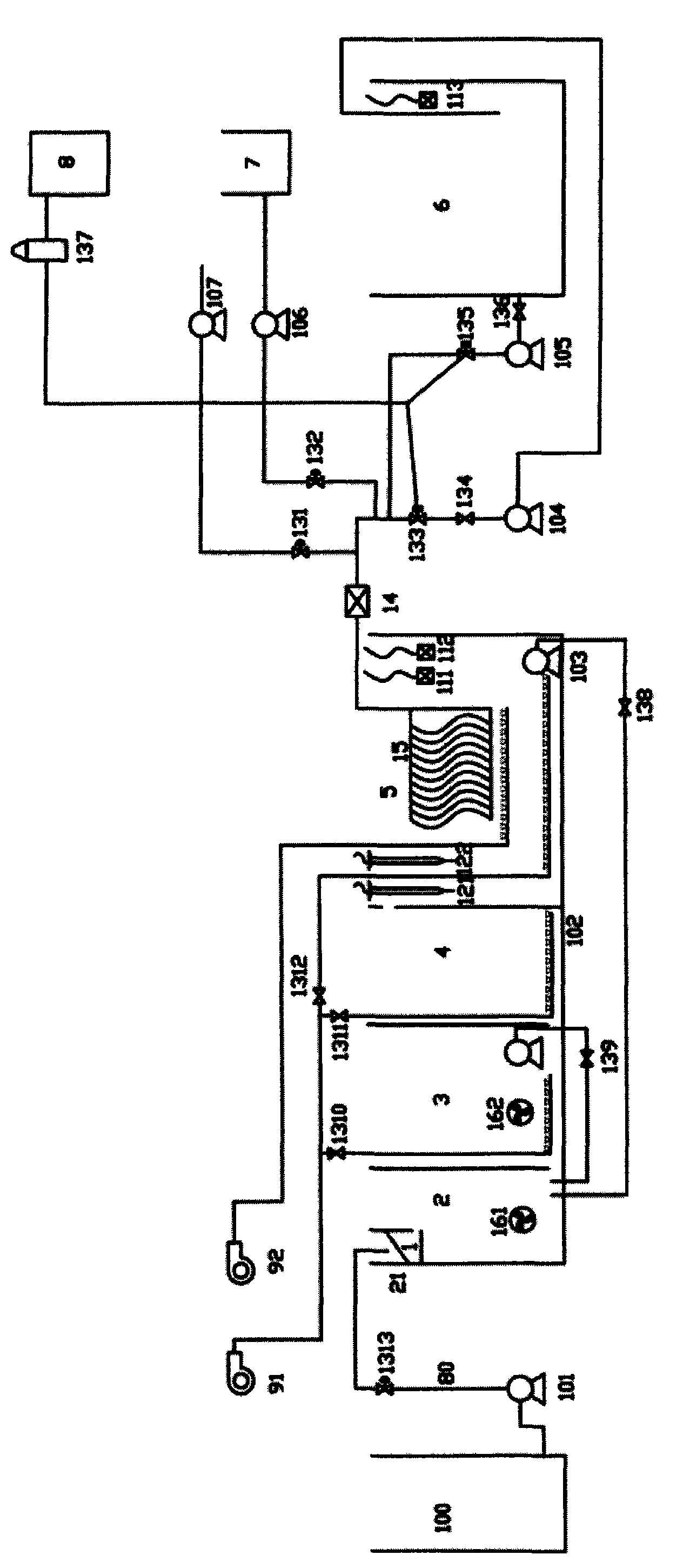

[0040] According to figure 1 , Take the MSG wastewater treatment example to illustrate the process flow and system equipment of the present invention.

[0041] Such as figure 1 As shown, the main components of the wastewater treatment of the present invention include an anaerobic effluent tank 100, an anoxic tank 2, a first-stage aerobic tank 3, a second-stage aerobic tank 4, and a membrane tank 5 which are connected in sequence in liquid communication, wherein the anaerobic effluent tank 100 It is in liquid communication with the anoxic tank 2 through the pipeline 80, the bottom of the anoxic tank 2 is connected to the bottoms of the tanks 3 and 4, and the mixed liquid of the tank 4 overflows to the tank 5, so the sludge and the treated liquid can flow Go to the next processing device.

[0042] MSG wastewater undergoes a common anaerobic (UASB) process, and the COD value of the wastewater is reduced from 4000-5000mg / L to 300-1000mg / L. When the anaerobic effluent fluctuates greatl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| denitrification rate | aaaaa | aaaaa |

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com