Rubber color master-batch and preparation method thereof

A color masterbatch and rubber technology, applied in the field of rubber color masterbatch and its preparation, can solve the problems of poor rubber medium dispersion performance, poor light resistance, insufficient color development of pigments, etc., to increase absorption and reflection, improve light resistance, reduce The effect of surface energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

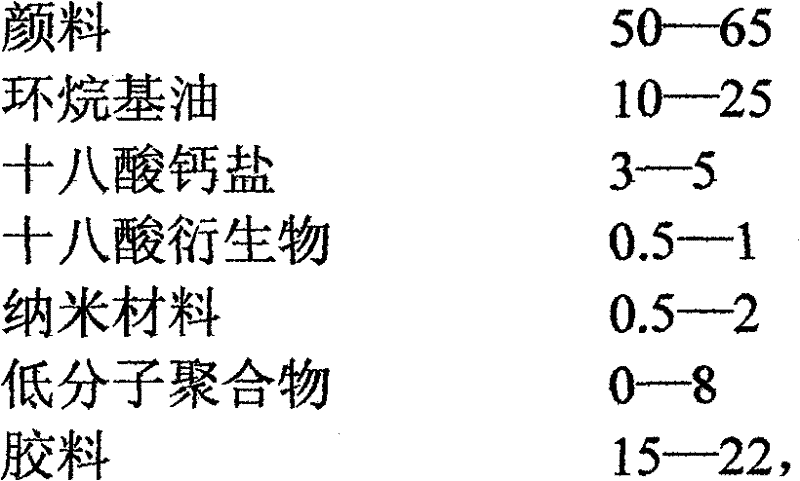

Method used

Image

Examples

Embodiment 1

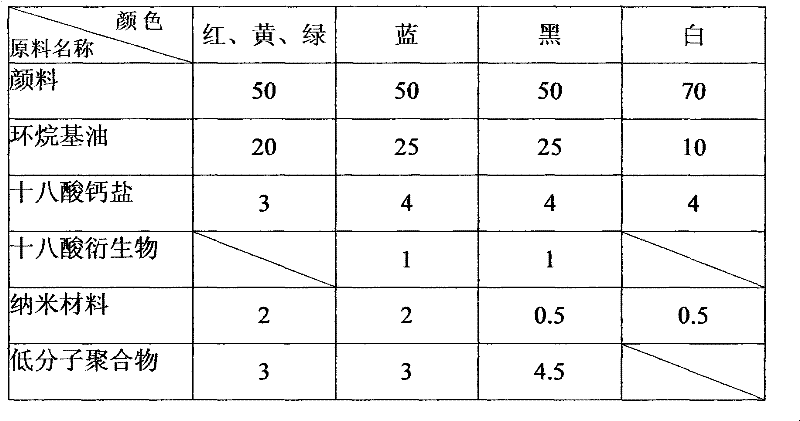

[0042] Preparation of red or yellow or green rubber masterbatch

[0043] In a 500l kneader, add 20Kg of alkyl oil, 3Kg of calcium octadecanoate, 3.5Kg of polyethylene with a molecular weight of 1500, start stirring, gradually raise the temperature to 85-90°C, and keep it warm for 1 hour; cool down to 50-55°C, Add 50Kg of the corresponding red, yellow or green pigments among the above-mentioned commonly used pigments, knead and moisten for 1-1.5 hours; add 0.5Kg of octadecyl imidazoline, mix for 0.5 hours, then grind on a three-roller machine, pour the ground material into In a 500L kneader for blending, start stirring, add 21Kg of rubber material and heat up to 65°C and mix for 1.5 hours, add 2Kg of nano-scale silica material, and mix for another 0.5 hour, take out the rolled sheet and cut to obtain the finished product.

[0044] The enterprise standard was adopted for testing, and the results are as follows:

[0045] project

Embodiment 2

[0047] Preparation of blue rubber masterbatch:

[0048] In a 500l kneader, add 25Kg of alkyl oil, 5Kg of octadecanoic acid calcium salt, and 3.5Kg of polyethylene with a molecular weight of 1500, start stirring, gradually heat up to 85-90°C, and keep warm for 1 hour; cool down to 50-55°C, Add 50Kg of blue pigment, knead and moisten for 1-1.5 hours; add 1Kg of octadecyl imidazoline, mix for 0.5 hours, then grind on a three-roller machine, pour the ground material into a 500L kneader for blending, start stirring, add After heating 13.5Kg of the rubber material to 80°C and keeping it warm for 4 hours, add 2Kg of nano-scale silicon dioxide material, mix for another 0.5 hour, take out the rolled sheet and cut it to obtain the finished product.

[0049] Enterprise standards are used for testing, which meet the standard indicators.

Embodiment 3

[0051] Preparation of black rubber masterbatch:

[0052] In a 500l kneader, add 25Kg of alkyl oil, 5Kg of octadecanoic acid calcium salt, 8Kg of polyethylene with a molecular weight of 1500, start stirring, gradually raise the temperature to 85-90°C, and keep it warm for 1 hour; cool down to 50-55°C, add Knead and wet 50Kg of black pigment for 1.5 hours; add 1Kg of octadecyl imidazoline, mix for 0.5 hours, then grind on a three-roll machine, pour the ground material into a 500L kneader for blending, start stirring, and add 10.5Kg of rubber After raising the temperature to 90°C and keeping it warm for 1 hour, add 1Kg of nano-sized zinc oxide material, mix for another 0.5 hour, take out the rolling sheet and cut it to obtain the finished product.

[0053] Enterprise standards are used for testing, which meet the standard indicators.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com