Light conversion master batch and preparation method thereof

A technology for light-converting masterbatches and masterbatches, applied in chemical instruments and methods, luminescent materials, etc., can solve problems such as inability to synchronize the service life of plastic films, hinder the application of light-converting agents, and unreported fluorescence life, and improve light attenuation. properties, protection against oxidation and deliquescence, ease of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0064] (1) Synthesis of red light conversion agent: weigh 64.5g CaCO according to the stoichiometric ratio 3 , 24.8g sulfur powder, 0.52g Eu 2 o 3 , 4.6gNH 4 Cl, then the raw materials were mixed, fully ground, calcined at 800°C for 2 hours under a CO reducing atmosphere, and gradually cooled to obtain the sample (A1), which was red in color.

[0065] The general formula of A1 is: CaS:Eu,Cl.

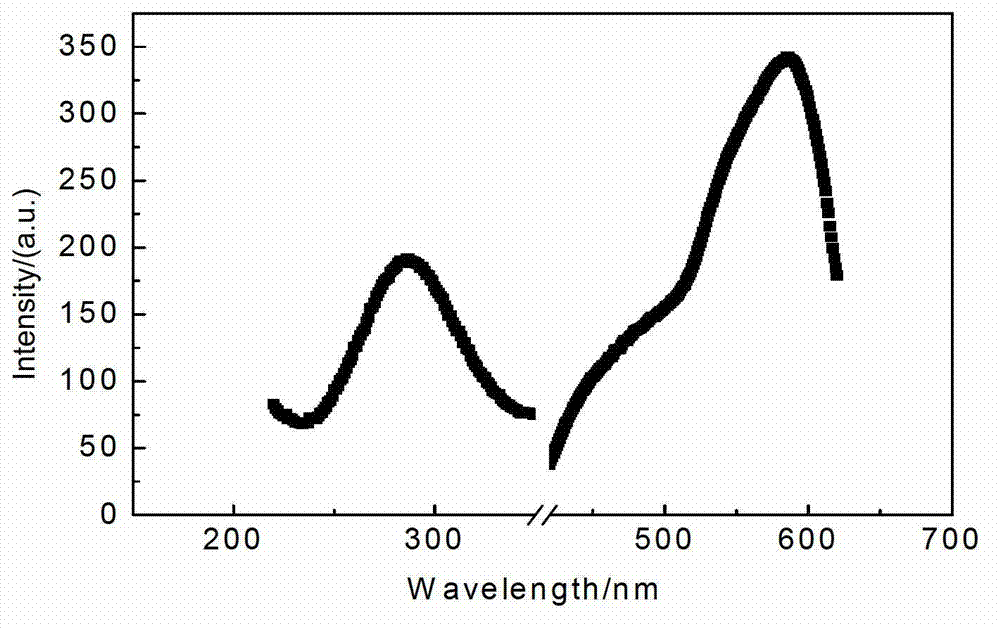

[0066] Excitation spectrum see figure 1 . figure 1 It shows that the light conversion agent (A1) can effectively absorb ultraviolet light and yellow-green light that plants do not absorb or absorb weakly in photosynthesis, and avoid the absorption spectrum of photosynthesis. characteristic wavelength of red light.

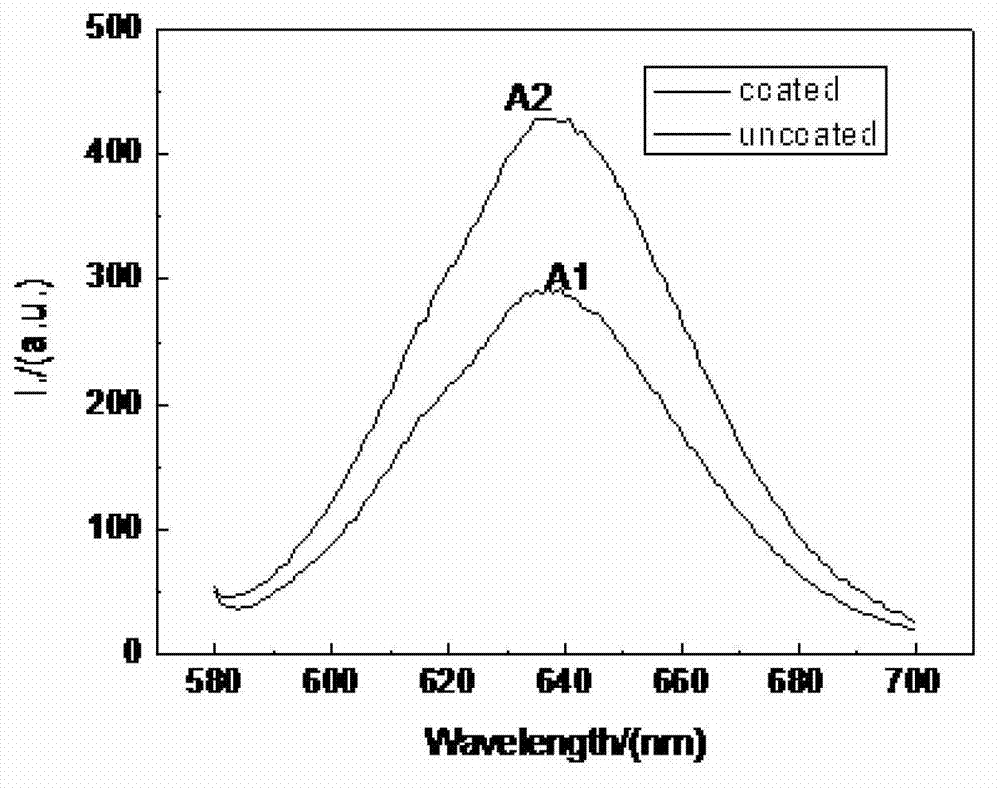

[0067] For the emission spectrum see figure 2 . figure 2 It shows that the light conversion agent (A1) can absorb ultraviolet light and yellow-green light and emit red light needed for plant photosynthesis, and its spectrum is very consistent with the photosynthesis...

Embodiment 2

[0079] (1) Synthesis of red light conversion agent: weigh 64.5g CaCO according to the stoichiometric ratio 3 , 24.8 sulfur powder, 0.52g Eu 2 o 3 , 4.6g Li 2 CO 3 , mix the raw materials, grind them thoroughly, bake at 850°C for 2 hours in a CO reducing atmosphere, and gradually cool down to obtain the sample (B1), which is orange-red.

[0080] The general formula of B1 is: CaS:Eu, Li.

[0081] Experiments have shown that the excitation spectrum of B1 is the same as that of A1, and it can also absorb ultraviolet light and yellow-green light that are not needed for photosynthetic growth of plants or that absorb weaker light.

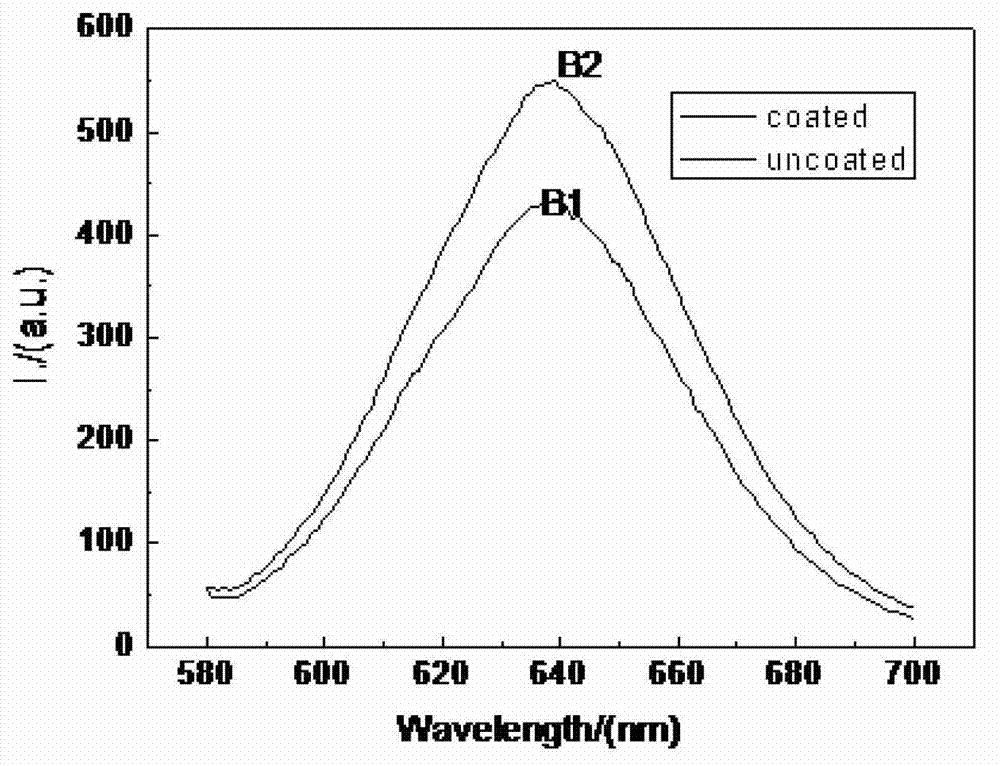

[0082] For the emission spectrum see image 3 . image 3 It shows that the light conversion agent (B1) can absorb ultraviolet light and yellow-green light and emit red light needed for plant photosynthesis, and its spectrum is very consistent with the photosynthesis spectrum.

[0083] Since carbonate and easily sublimable sulfur powder are used as ...

Embodiment 3

[0094] (1) Synthesis of red light conversion agent: weigh 64.5g CaCO according to the stoichiometric ratio 3 , 24.8 sulfur powder, 0.52g Eu 2 o 3 , 4.6g CaCl 2 , mix the raw materials, grind them thoroughly, bake at 900°C for 2 hours under a CO reducing atmosphere, and gradually cool down to obtain a sample (C1), which is red in color.

[0095] The general formula of C1 is: CaS:Eu,Cl.

[0096] Experiments show that: the excitation spectrum of C1 is the same as that of A1, and it can also absorb ultraviolet light and yellow-green light that are not needed for photosynthetic growth of plants or absorb weaker ones.

[0097] For the emission spectrum see Figure 4 . Figure 4 It shows that the light conversion agent (C1) can absorb ultraviolet light and yellow-green light and emit red light needed for plant photosynthesis, and its spectrum is very consistent with the photosynthesis spectrum.

[0098] Since carbonate and easily sublimable sulfur powder are used as raw materia...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com