Waste oil treatment system and method

An oil treatment and oil storage tank technology, which is applied in the multi-stage series refining process treatment, petroleum industry, refined hydrocarbon oil, etc., can solve the problems of low efficiency, no waste oil regeneration treatment technology, environmental protection problems, and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

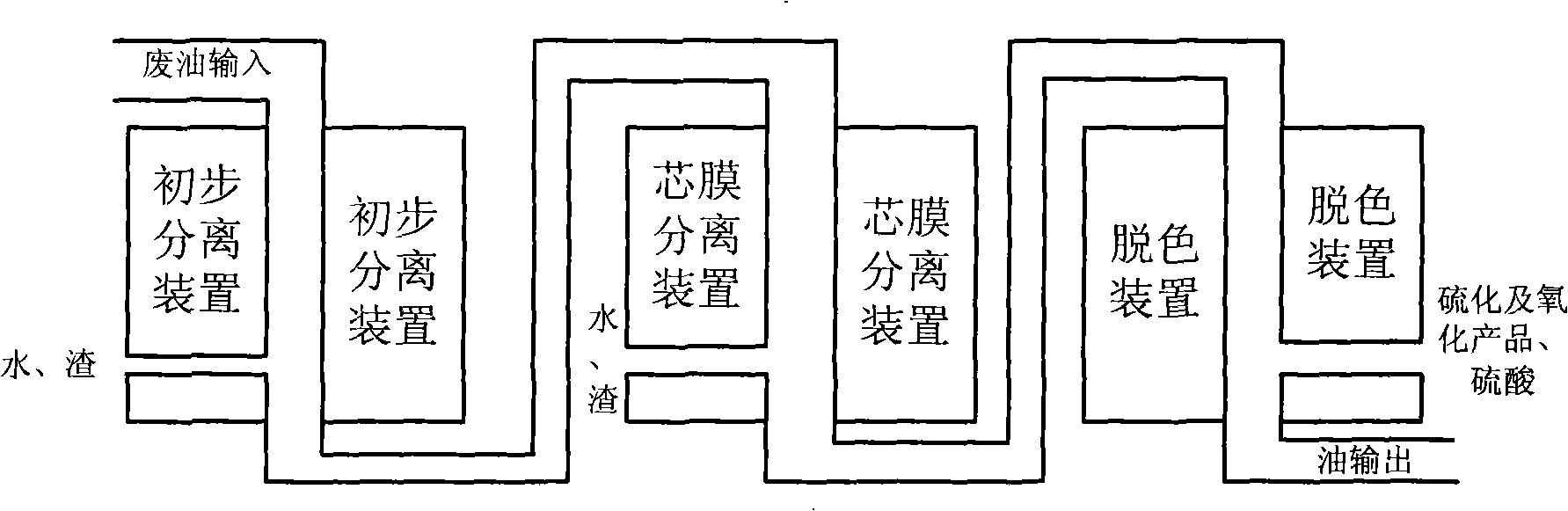

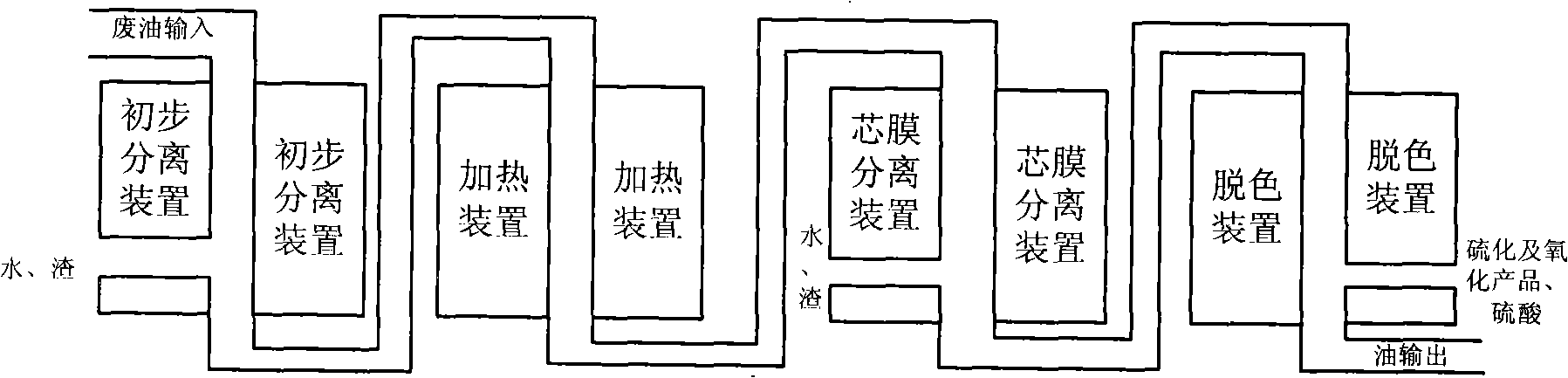

[0031] refer together figure 1 and figure 2 , the waste oil treatment system of the present invention mainly comprises:

[0032] Preliminary separation device for preliminary separation of oil, water and slag from waste oil;

[0033] Decolorization device for decolorization of waste oil;

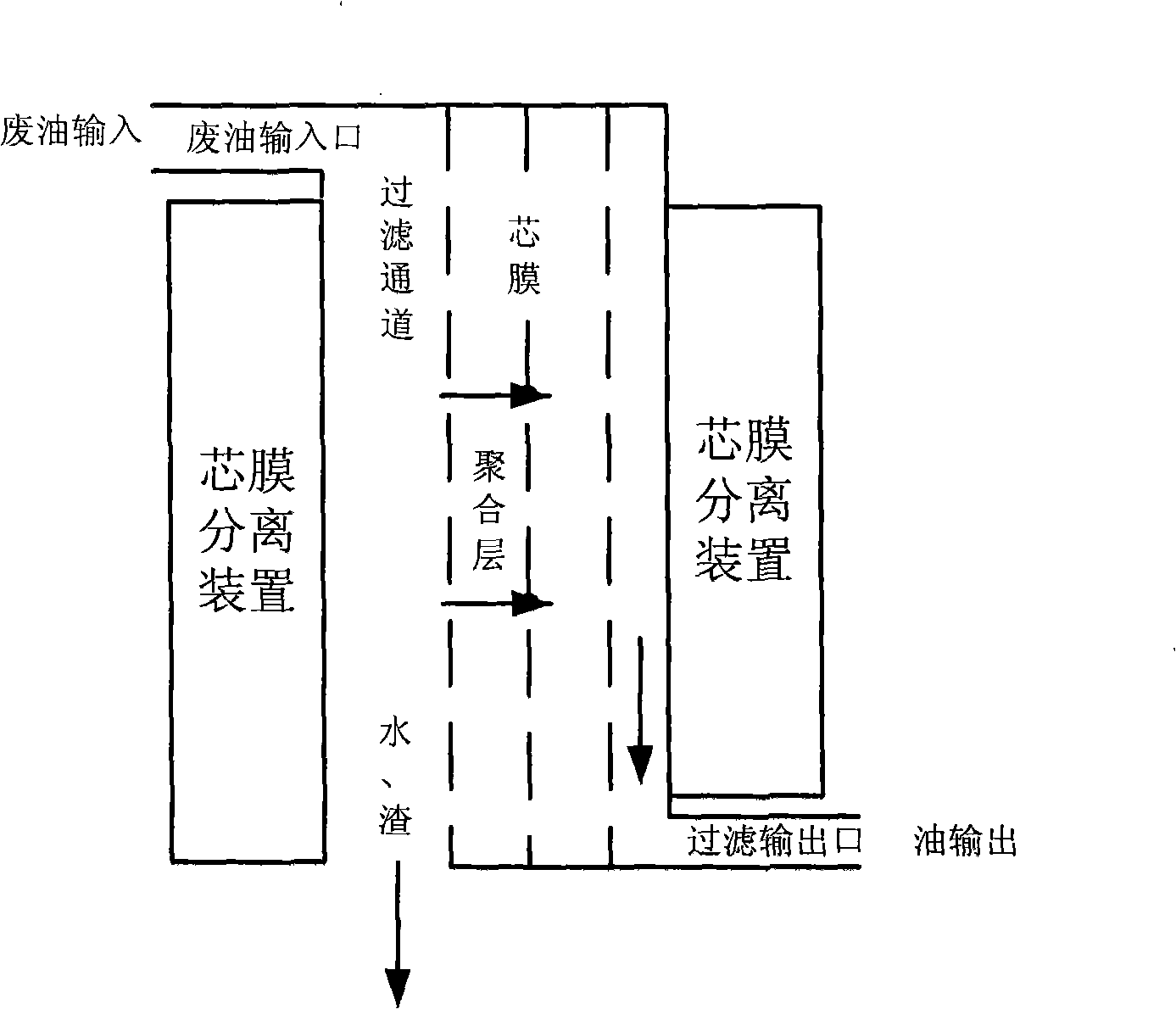

[0034] Comprising a core membrane separation device connected between the primary separation device and the decolorization device, the core membrane separation device includes:

[0035]A core membrane for filtering waste oil comprising a polymeric layer that repels water molecules and solid molecules through oil molecules.

[0036] When in use, the waste oil enters from the preliminary separation device, passes through the preliminary separation device, core membrane separation device and decolorization device in sequence, and simultaneously undergoes preliminary separation treatment, core membrane separation treatment and decolorization treatment in sequence, and finally the treated oil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com