Checker brick with plum blossom hole for air heating furnace

A technology of checker bricks and plum blossom holes, which is applied in the field of checker bricks, can solve the problems of small heat storage area, small hot air flow rate, and small hole diameter, and achieve the effects of enhancing heat storage capacity, increasing blast furnace temperature, and reducing the proportion of coke

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments, where the schematic embodiments and descriptions of the present invention are used to explain the present invention, but not to limit the present invention.

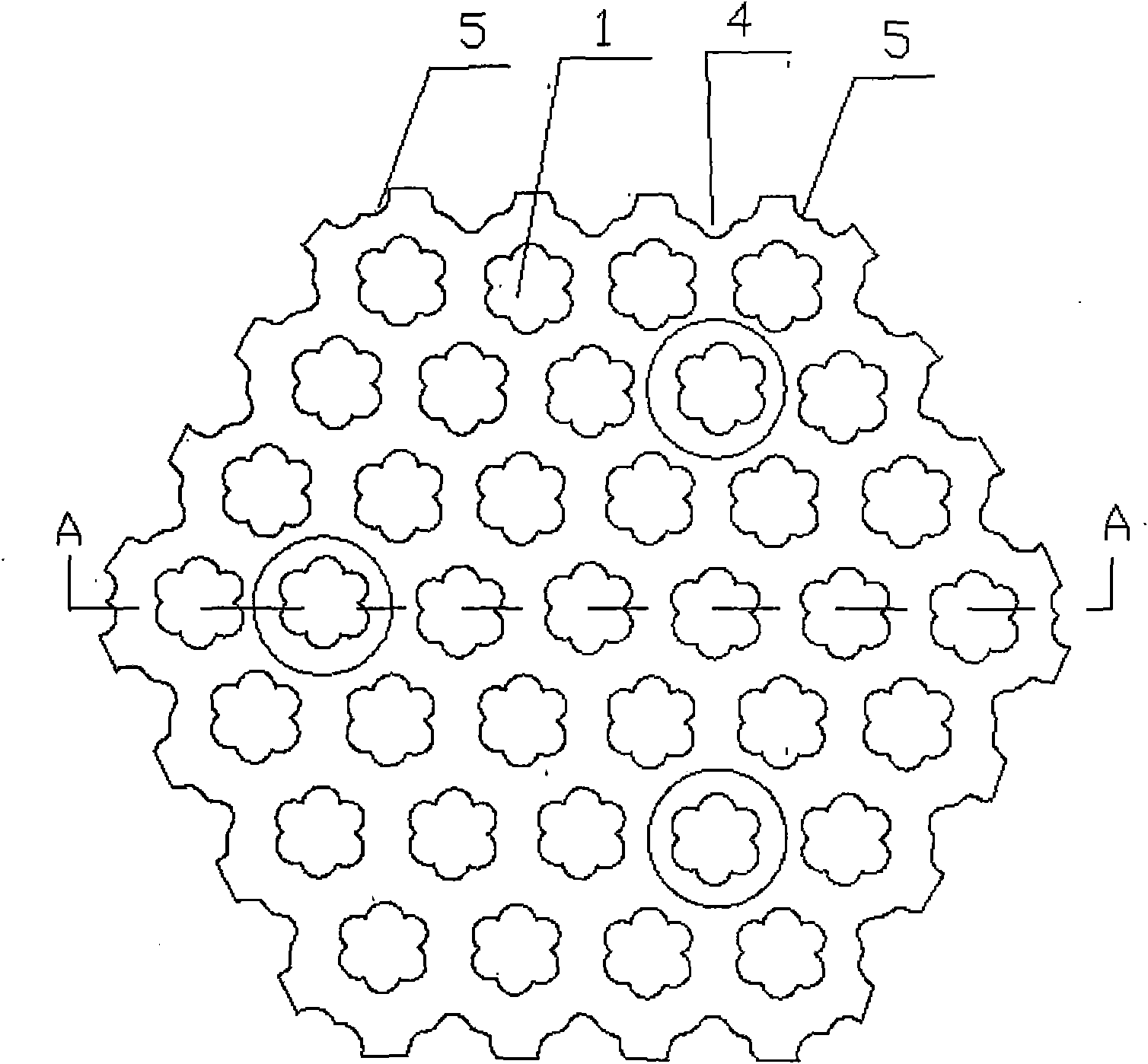

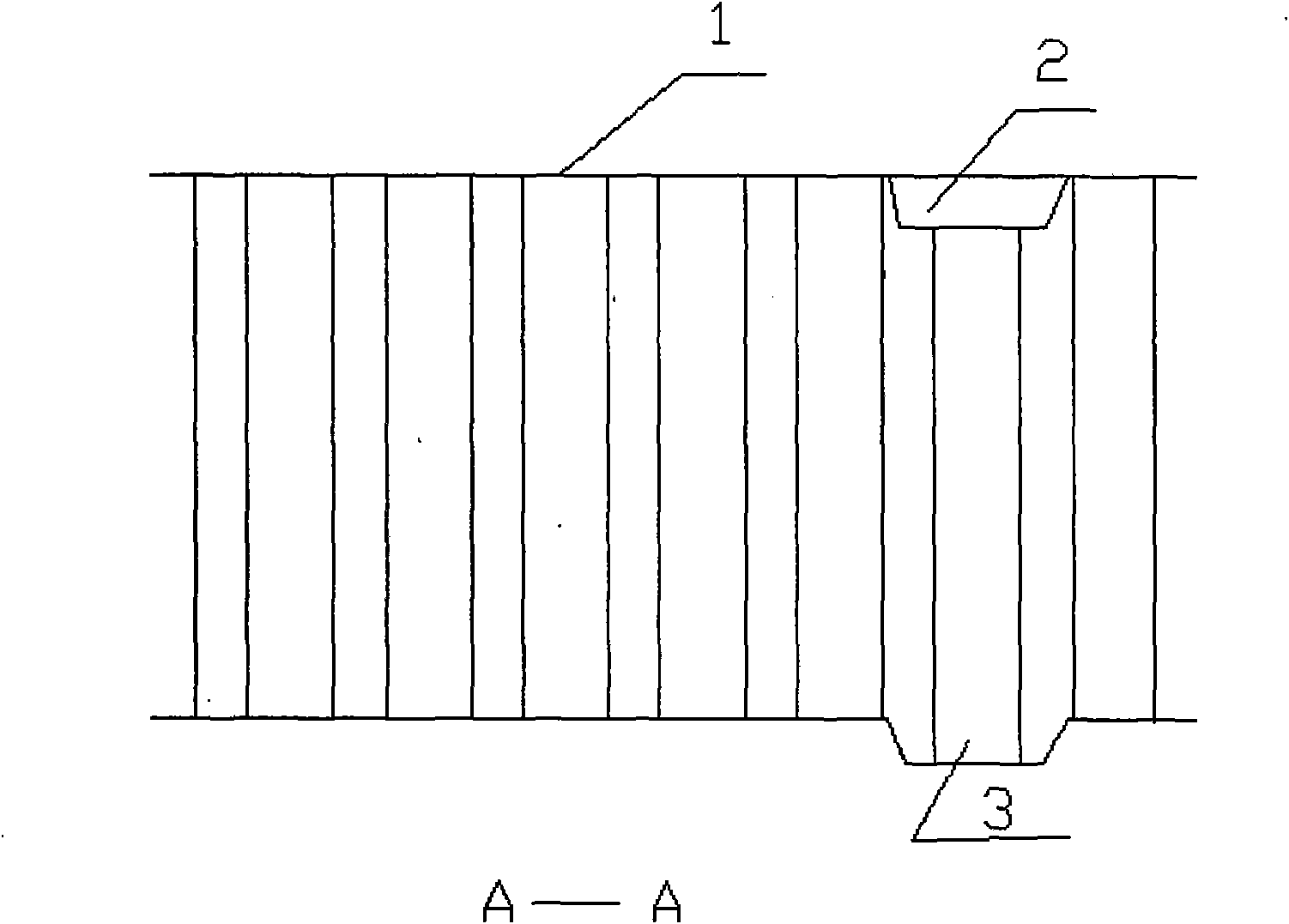

[0017] Such as Figure 1-2 As shown, in the plum-blossom-shaped checker bricks for hot blast stoves provided in this embodiment, through-holes 1 are arranged on the checker bricks, and the through-holes 1 are arranged equidistantly. It is composed of six 120-degree circular arcs of the same size connected end to end; the periphery of the checker brick is provided with a semi-quincunx-shaped hole 4 and a 120-degree circular arc hole 5 composed of three 120-degree circular arcs connected in sequence, and the checker brick Grooves 2 are provided on the upper end surface, and bumps 3 are provided at corresponding positions on the lower end surface of the checker brick.

[0018] The through h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com