A safety protecting work trolley for chamber

A safety protection and workbench technology, which is applied in underground chambers, shaft linings, tunnel linings, etc., can solve the problems of low safety protection level, large operation risks, complex and changeable excavation working faces, etc., and achieve high safety protection design. level, improve safety protection ability, and improve the effect of ground adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

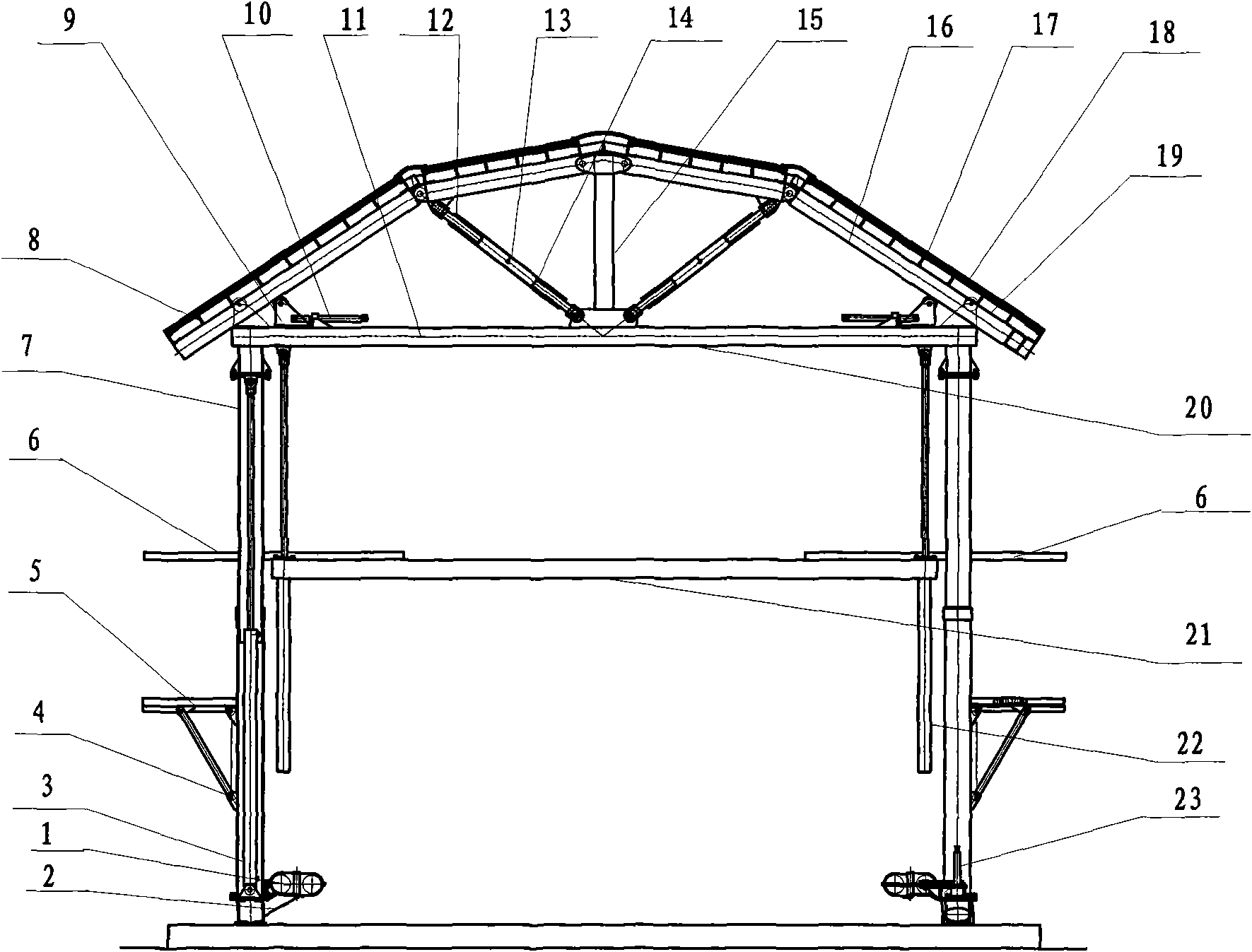

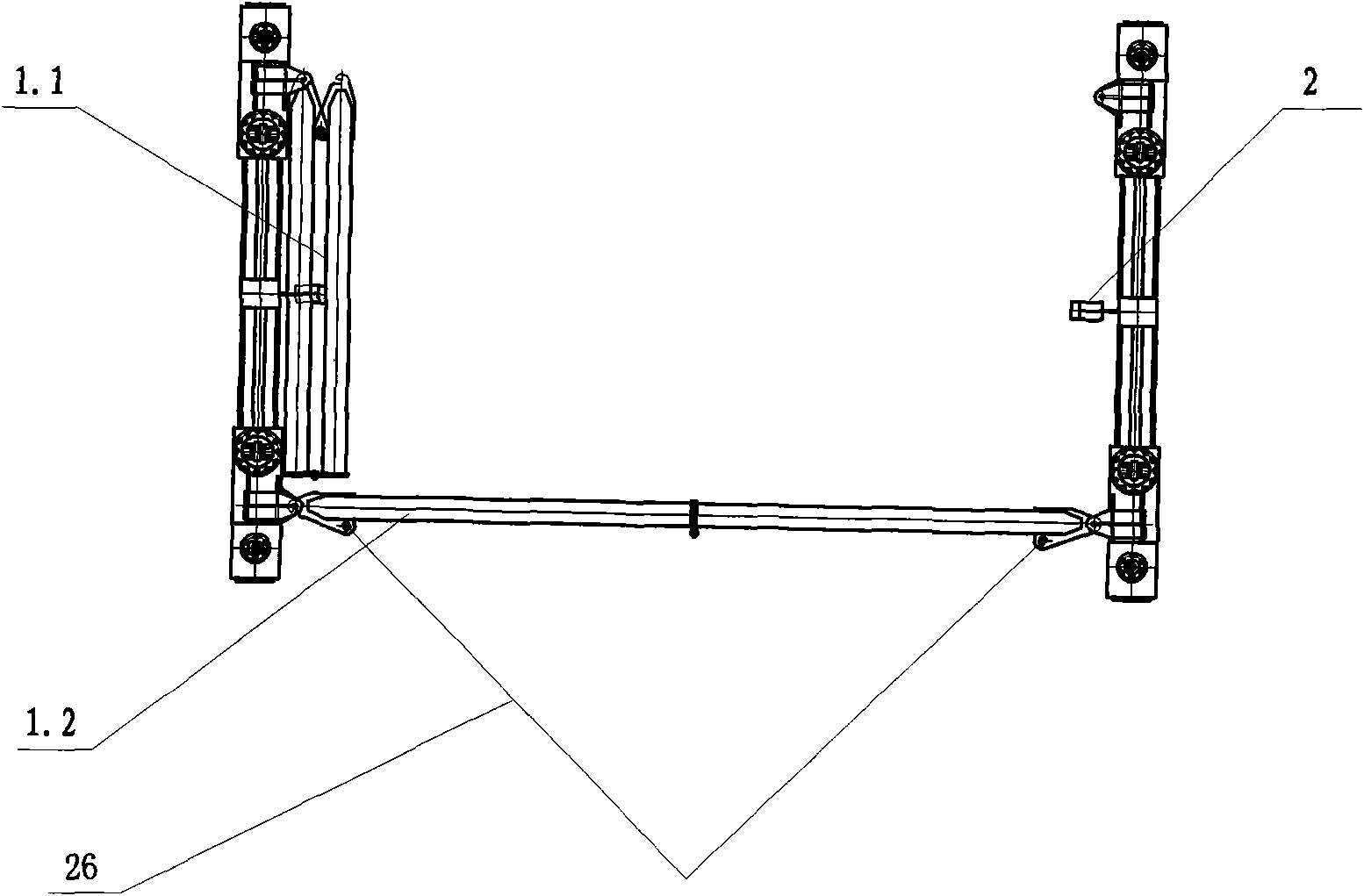

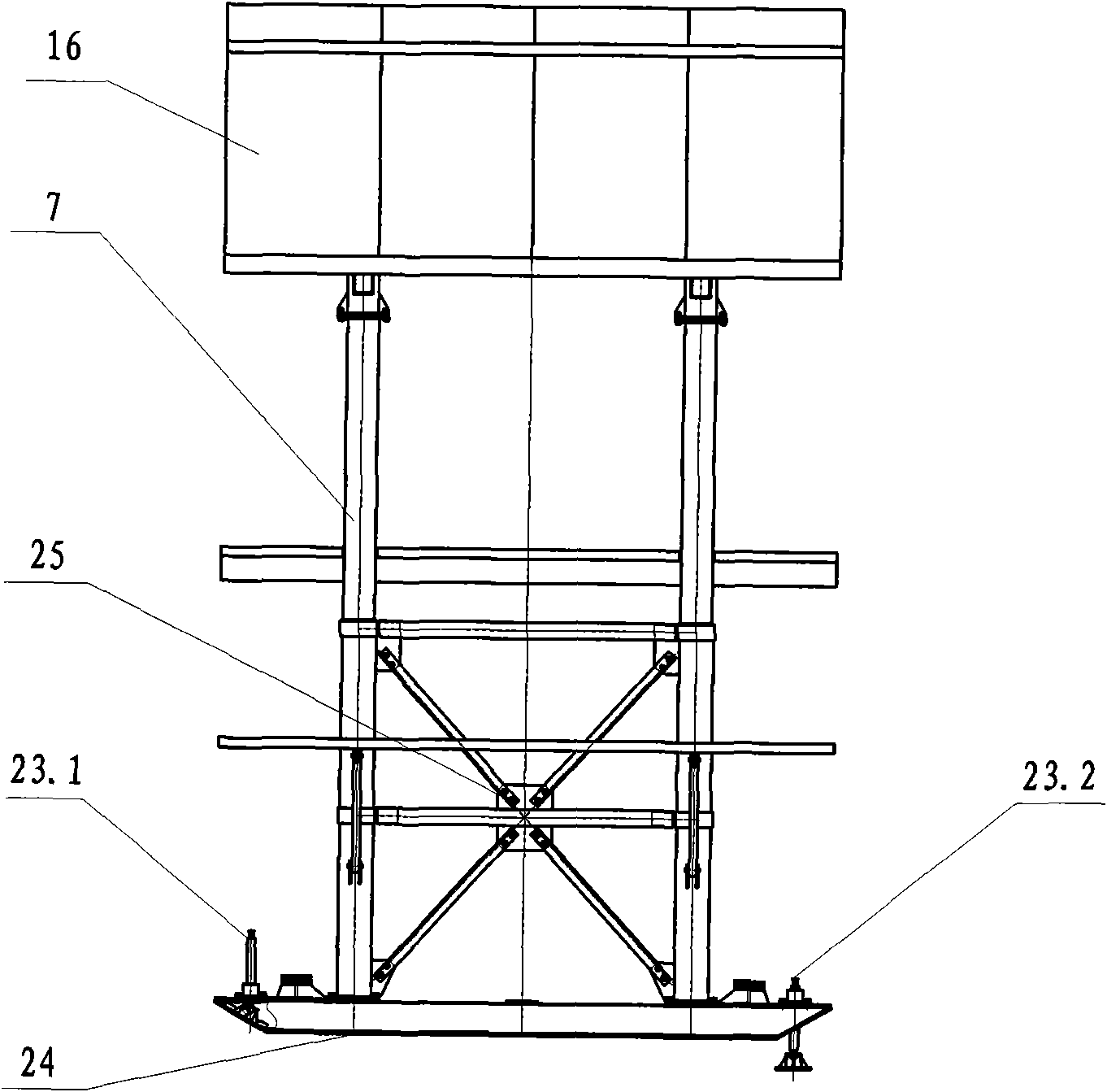

[0014] see Figure 1-Figure 4 , the present invention includes a protective shed 16, a work platform, an adjustment device and a mobile device, and the protective shed 16 is supported on the mobile device by a column 7. Its key technology is that the column 7 is a sleeve-type column, which is sheathed together by two pipe columns inside and outside, and the column lifting oil cylinder 3 is installed in the middle of the pipe column. The protective shed 16 is mainly composed of a protective roof truss and an expanded metal mesh 17. The protective roof truss includes a horizontal bar 11, a vertical bar 15 and an oblique bar 18. The horizontal bar 11 is connected end to end and fixed on the top of the column 7, and two of them are parallel to each other. The middle part of 11 fixes vertical bar 15 respectively, and oblique bar 18 is installed respectively between the top of vertical bar and the two ends of horizontal bar, constitutes the protective roof truss with symmetrical slo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com