Sealing optical fiber device at low temperature

A sealing device and optical fiber technology, which is applied to the coupling of optical waveguides and other directions, can solve the problems of reduced sealing performance, high cost, and small number of sealed optical fibers, and achieve the effects of simple sealing structure, simple method and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

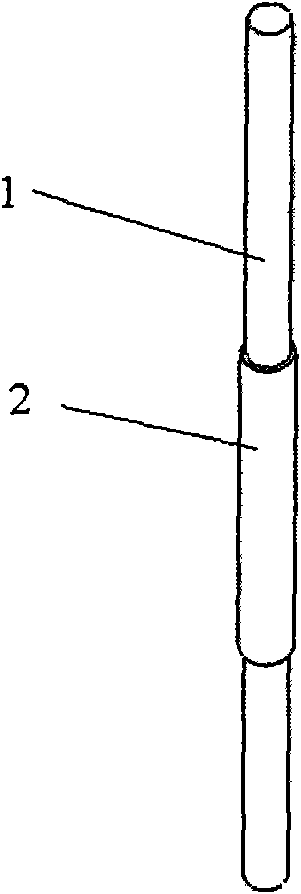

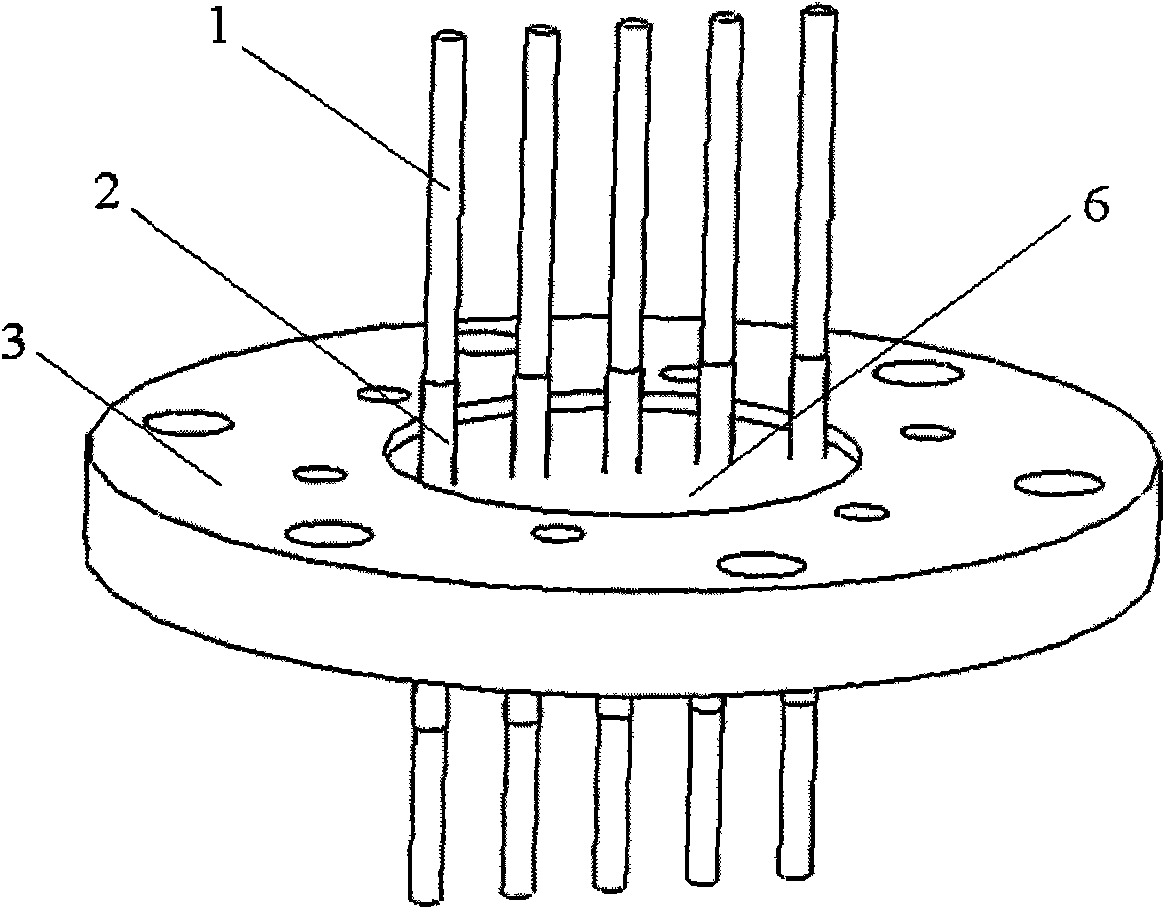

[0015] Such as figure 1 As shown, a metal layer 2 is coated on the outer surface of the optical fiber 1 by magnetron sputtering. The thickness of the metal layer 2 is 0.5mm-1mm, and the length of the metal layer 2 is 10mm greater than the height of the fiber sealing hole of the sealing flange. -15mm.

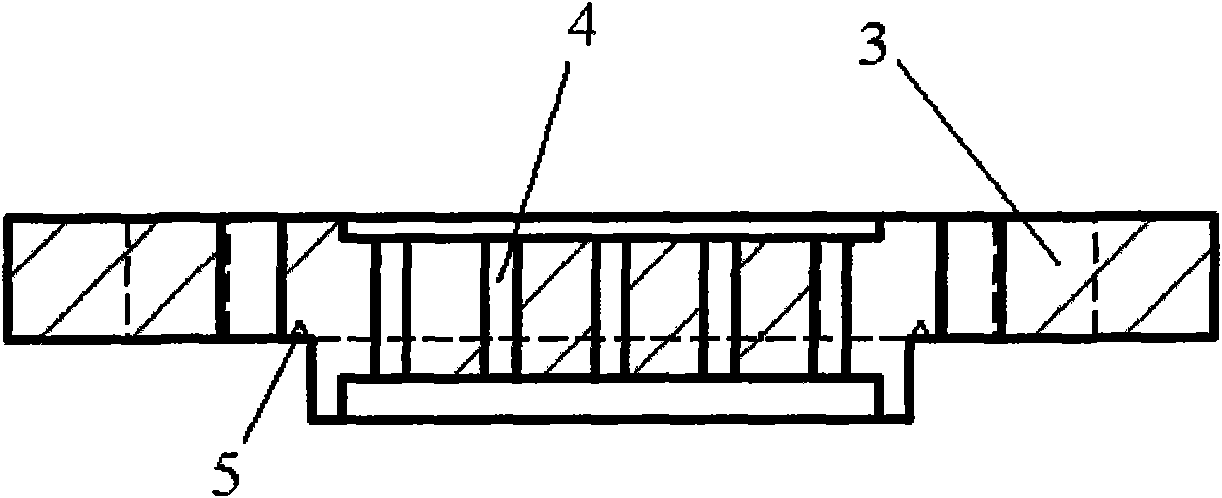

[0016] Such as figure 2 As shown, an optical fiber sealing hole 4 is opened in the center of the sealing flange 3, and a sealing groove 5 is formed on the lower end surface. The sealing flange 3 is made of stainless steel, and the sealing groove 5 has a width of 0.5-0.7mm and a depth of 0.4-0.6mm. After the optical fiber sealing hole 4 is sealed, metal indium wire is filled in the sealing groove 5 of the optical fiber flange, the sealing flange 3 is pressed tightly on the sealing port of the low-temperature container by screws, and the low-te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com