Battery module, electric storage device and electric system

一种电池模块、电池的技术,应用在输出功率的转换装置、二次电池、电池温度控制等方向,达到降低温度上升、降低充放电量和寿命的波动、降低压力损失的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

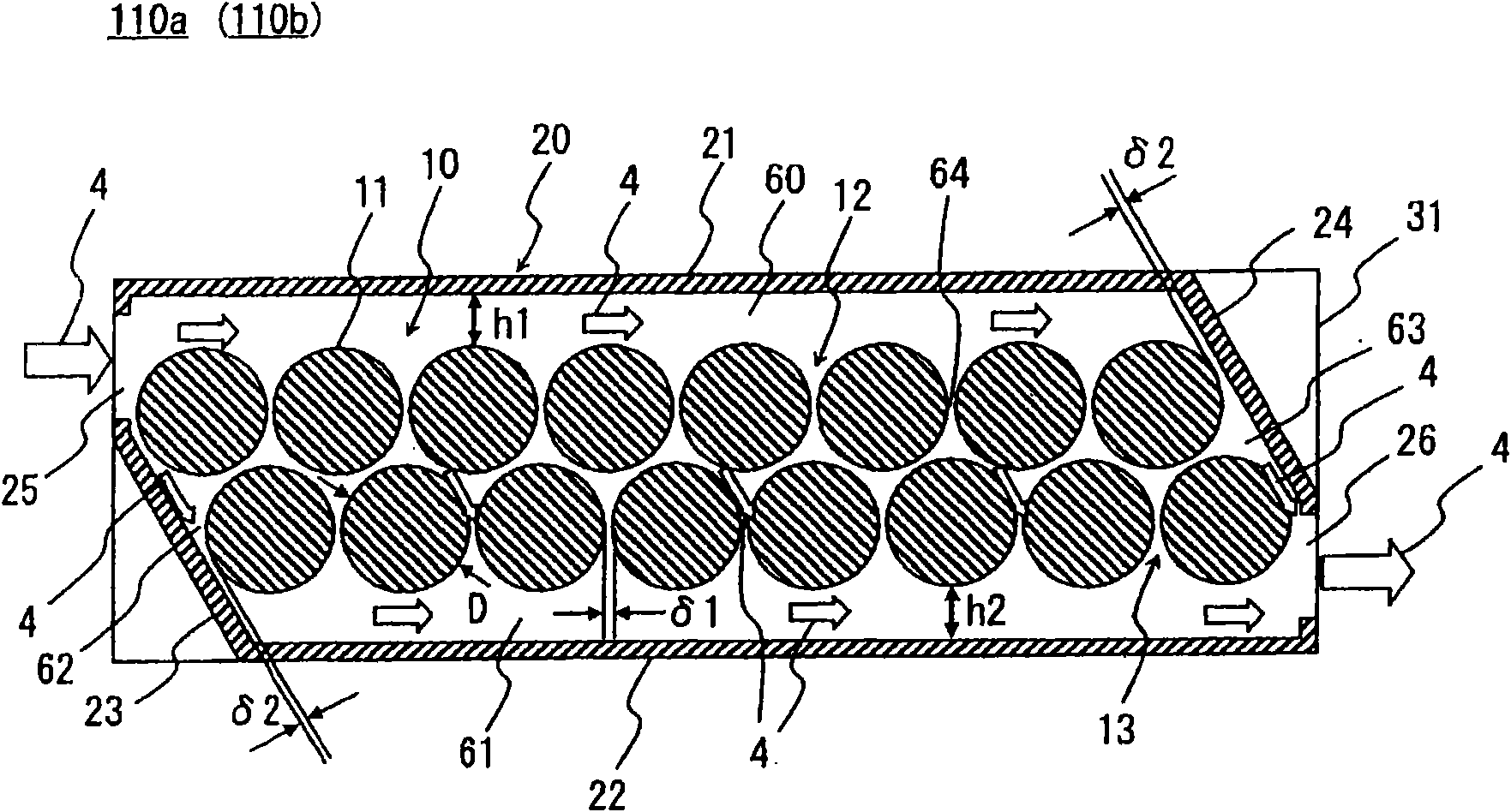

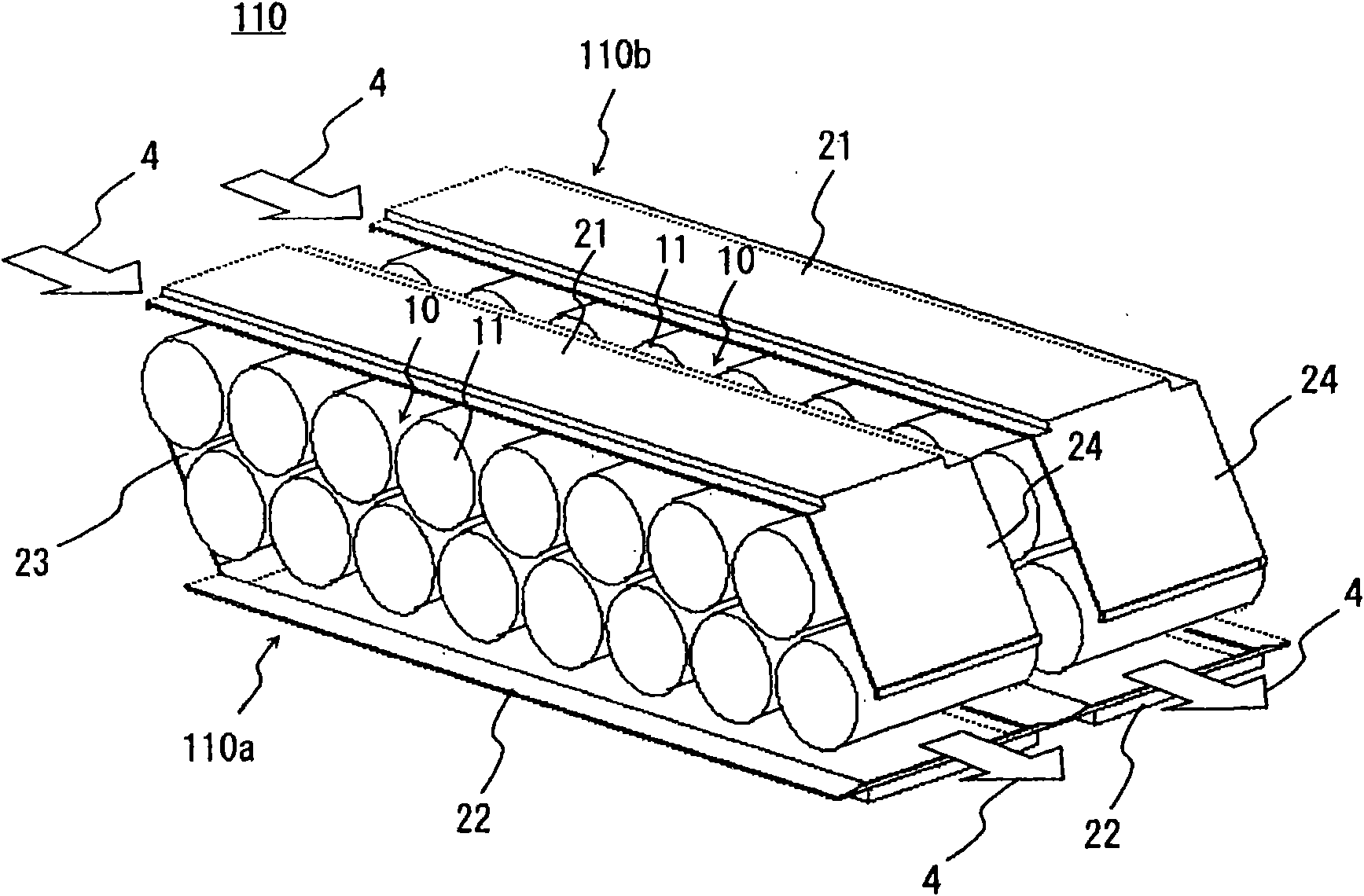

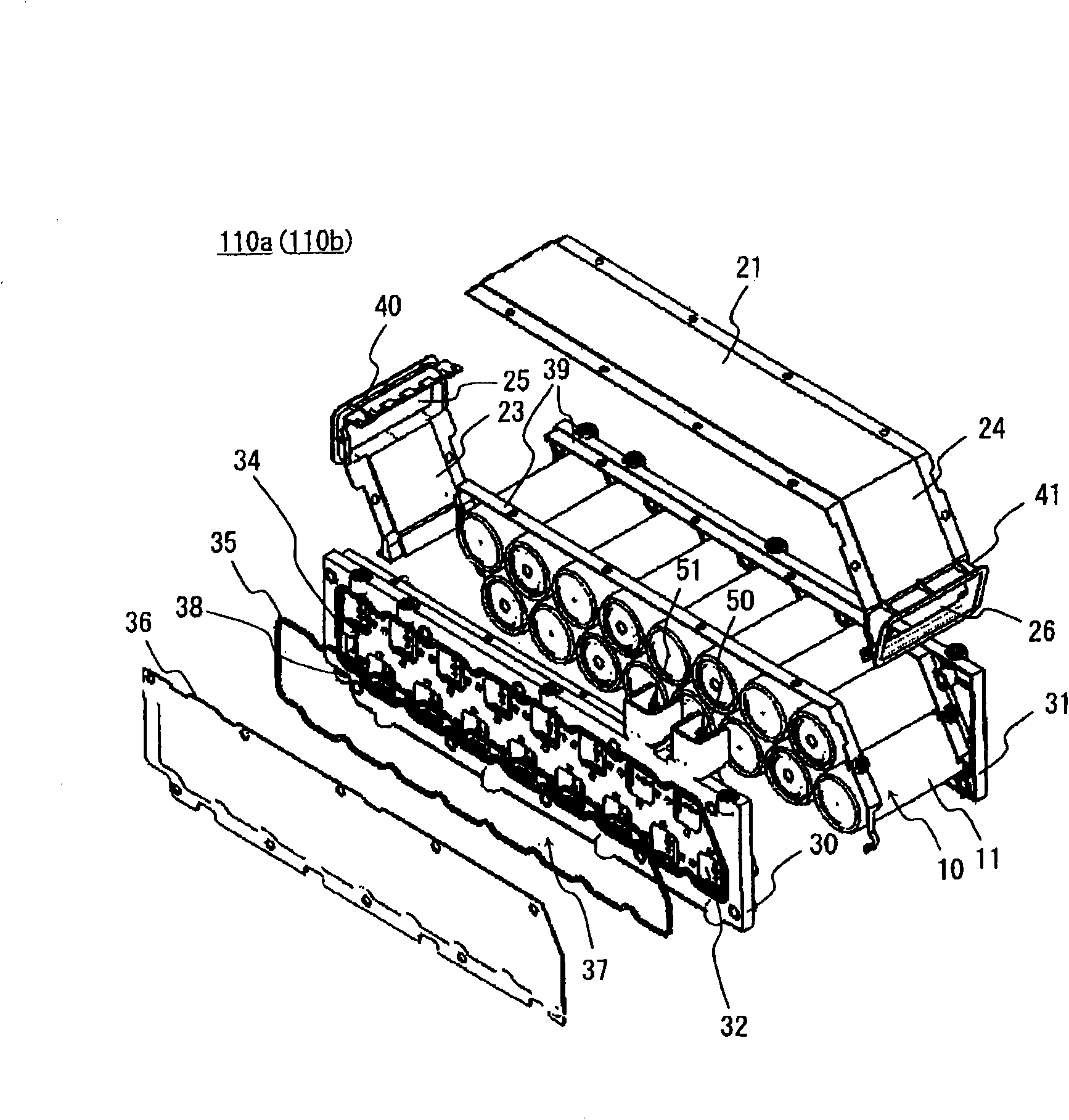

[0063] according to Figure 1-8 The first embodiment of the present invention will be described.

[0064] First, use Image 6 The configuration of an on-vehicle motor system (motor drive system) will be described.

[0065] The vehicle-mounted motor system of this embodiment drives the motor generator 200, which is a three-phase AC synchronous machine, as a motor when the vehicle is in an operation mode that requires rotational power, such as when the vehicle is towed or when the engine that is an internal combustion engine is started. Rotational power is supplied to driven bodies such as wheels and an engine. Therefore, the vehicle-mounted motor system of this embodiment outputs DC power from the power storage device 100, which is the vehicle-mounted power supply, and converts the output DC power into a three-phase AC power through the power conversion device, namely, an inverter device 300, and converts the converted three-phase AC power into a three-phase AC power. AC pow...

Embodiment 2

[0207] according to Figure 9 A second embodiment of the present invention will be described.

[0208] In the first embodiment, a cylindrical (column) shape was used as the lithium cell 11, but in this embodiment, a square cylinder (square column) shape may also be used. The length of one side in the cross-section in the short-side direction of the lithium cell 11 is equal to the diameter D of the cylindrical lithium cell 11 in the preceding example.

[0209] The structure other than that is completely the same as that of the first embodiment. Therefore, the same reference numerals as those in the first embodiment are attached to the same structures as those in the first embodiment, and description thereof will be omitted.

[0210] According to the present embodiment described above, the same effect as that of the first embodiment can be achieved.

Embodiment 3

[0212] according to Figure 10 A third embodiment of the present invention will be described.

[0213] This embodiment is an improved example of the first embodiment, and the height of the outlet-side flow path 61, that is, from the position closest to the outlet flow-path forming plate 22 side of the lithium cells 11 constituting the second cell row 13 to the outlet flow path The height h2 in the height direction of the inner wall surface of the channel forming plate 22 is greater than the height of the inlet side flow channel 60 , that is, from the position closest to the inlet channel forming plate 21 side of the lithium cells 11 constituting the first cell row 12 to the inlet. Height h1 in the height direction of the inner wall surface of the flow path forming plate 21 . Therefore, the dimensional ratio of the height h2 of the outlet-side channel 61 to the diameter D of the lithium cell is larger than the dimensional ratio of the height h1 of the inlet-side channel 60 to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com