Circuit base plate and manufacturing method thereof

A technology of circuit substrate and manufacturing method, which is applied in the direction of printed circuit manufacturing, printed circuit, printed circuit, etc., can solve the problems of large difference in expansion and shrinkage, easy peeling of conductive lines and substrates, warping of circuit board products, etc. Achieve the effects of avoiding impact, good electrical conduction, and not easy to warp

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

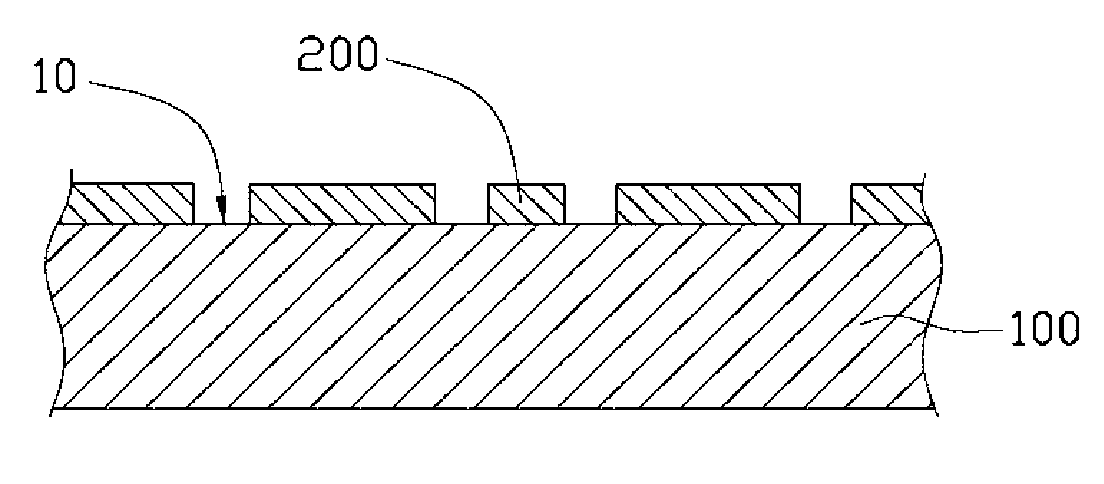

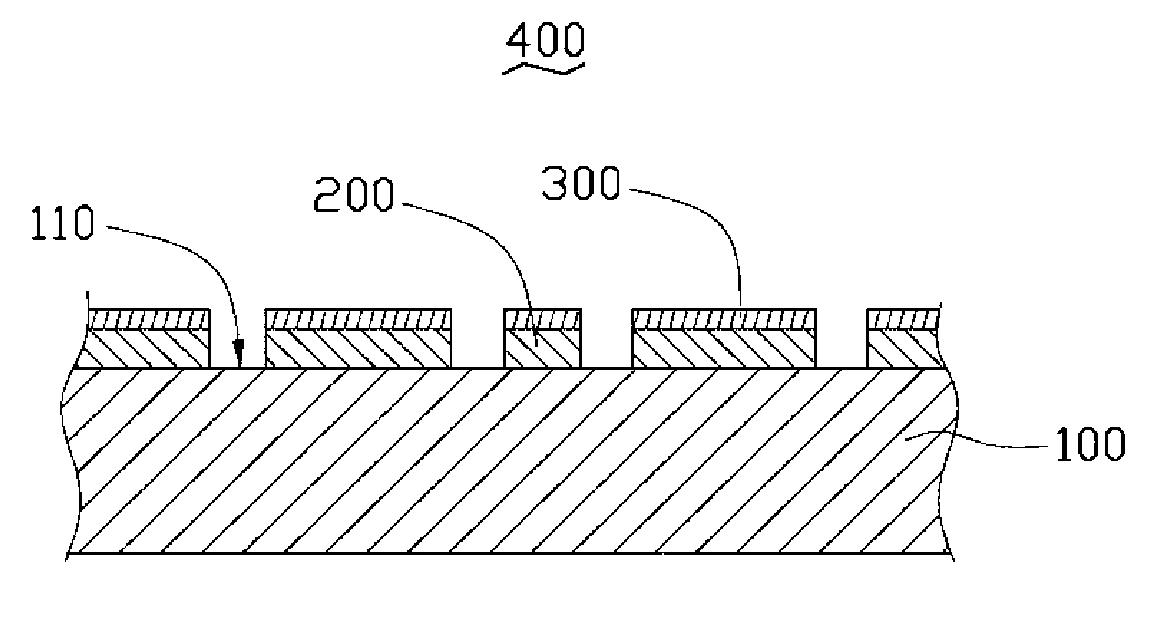

[0012] The circuit substrate and the manufacturing method of the circuit substrate provided by the embodiment of the technical solution will be further described in detail below with reference to the drawings and embodiments.

[0013] see Figure 1 to Figure 3 , the circuit substrate and the manufacturing method of the circuit substrate provided in this embodiment.

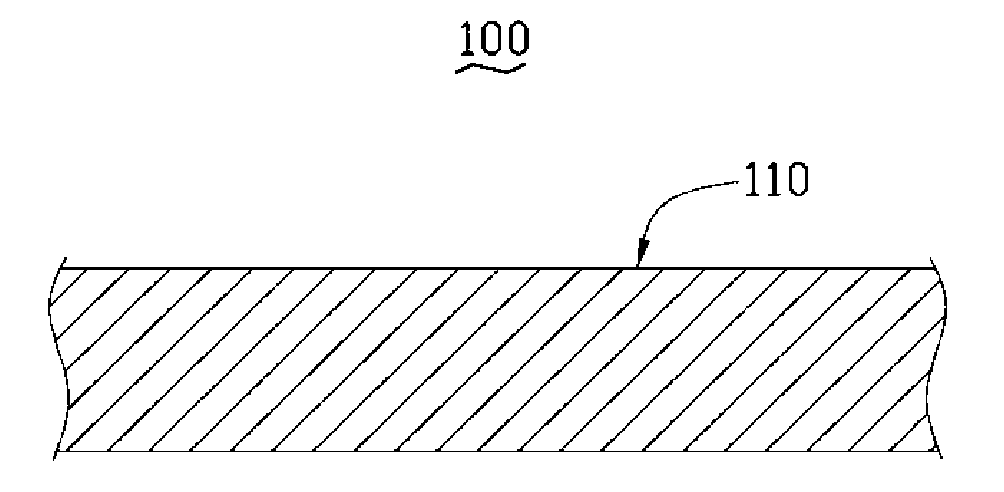

[0014] Step 1: providing a substrate 100 .

[0015] Such as figure 1 As shown, in this embodiment, the base material 100 is a semi-finished product that needs to be circuit-fabricated. The base material 100 with different structures can be selected as required. For example, the substrate 100 can be an insulating layer, and the insulating layer can be made of polyimide, polyester, liquid crystal polymer and other insulating materials. The base material 100 may also be a composite structure formed by laminating a multilayer circuit board and an insulating layer. In addition, the substrate 100 can also be a semi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com